Stainless steel doped perovskite ceramic dual-phase composite hollow fiber oxygen permeable membrane and preparation method thereof

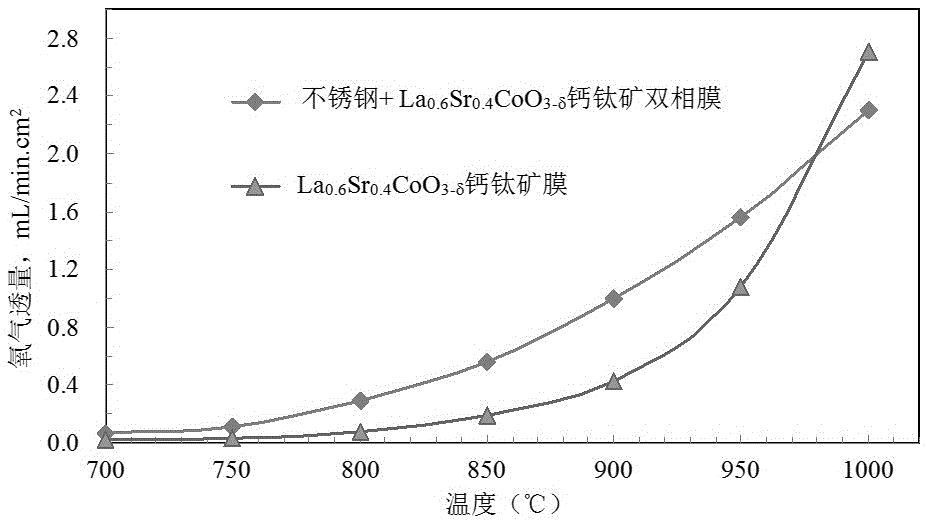

A perovskite and stainless steel technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of low mechanical strength and difficult assembly of membrane modules, and achieve high mechanical strength and easy assembly into membrane modules , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

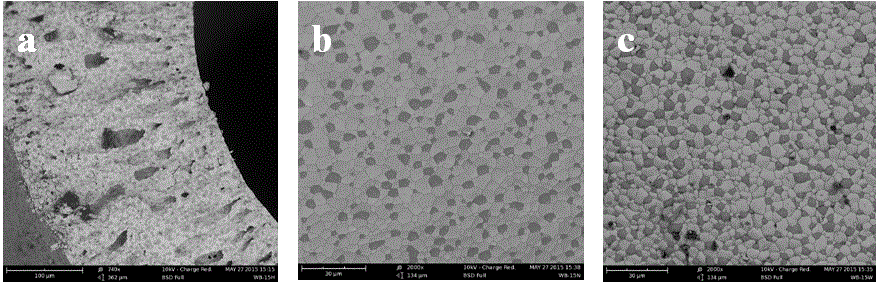

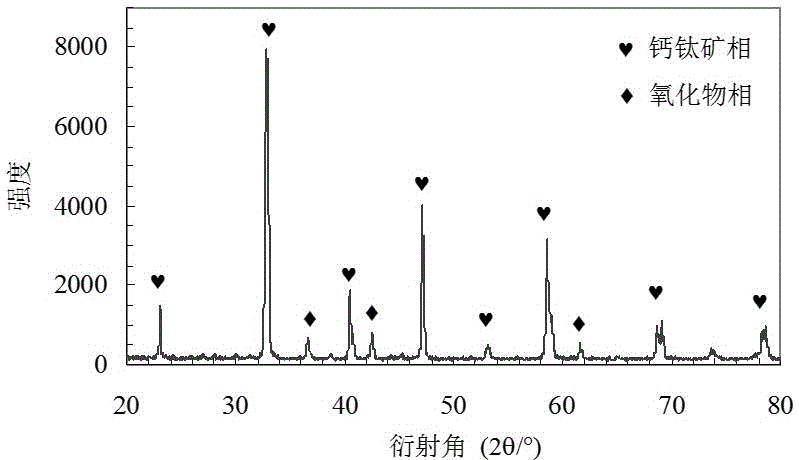

[0023] Embodiment 1: stainless steel powder is doped with La 0.6 Sr 0.4 CoO 3-δ Dual Phase Composite Hollow Fiber Membrane

[0024] Dissolve the dispersant polyvinylpyrrolidone in the organic solvent N-methylpyrrolidone, add stainless steel powder and perovskite ceramic powder La 0.6 Sr 0.4 CoO 3-δ , after fully wetting, add the polymer binder polysulfone in batches, and fully stir to obtain a uniform and stable casting solution, wherein the mass percentage of the organic polymer binder is 9%; the mass percentage of the organic solvent is 36%; 0.6 Sr 0.4 CoO 3-δ The content of ceramic powder is 47.7%; the content of dispersant is 2%; the mass percentage of stainless steel powder is 5.3%; the obtained casting solution is vacuum degassed for 3 hours, then moved to the spinning equipment tank, under nitrogen pressure, with pure water As the core liquid, the casting liquid is pressed into the gel bath water through the spinning head to undergo phase inversion molding, and ...

Embodiment 2

[0025] Embodiment 2: stainless steel powder doped with SrCo 0.8 sc 0.2 o 3-δDual Phase Composite Hollow Fiber Membrane

[0026] Dissolve the dispersant polyammonium methacrylate in the organic solvent N-methylpyrrolidone, add stainless steel powder with a particle size of 1-3 μm and perovskite ceramic powder SrCo 0.8 sc 0.2 o 3-δ , after fully wetting, add the polymer binder polyethersulfone in batches, and fully stir to obtain a uniform and stable casting solution, wherein, the mass percentage of the organic polymer binder is 9%; the mass percentage of the organic solvent 53%; SrCo 0.8 sc 0.2 o 3-δ The content of ceramic powder is 34.2%; the content of dispersant is 2%; the mass percentage of stainless steel powder is 1.8%; the obtained casting solution is vacuum degassed for 5 hours, then moved to the spinning equipment tank, under nitrogen pressure, with pure water As the core liquid, the casting liquid is pressed into the gel bath water through the spinning head to...

Embodiment 3

[0027] Embodiment 3: stainless steel powder doped with La 0.6 Ca 0.4 FeO 3-δ Dual Phase Composite Hollow Fiber Membrane

[0028] Dissolve the dispersant methyl methacrylate in the organic solvent N,N-dimethylformamide, add stainless steel powder and perovskite ceramic powder La with a particle size of 1-3 μm 0.6 Ca 0.4 FeO 3-δ , after fully wetting, add the polymer binder polyethersulfone in batches, and fully stir to obtain a uniform and stable casting solution, wherein, the mass percentage of the organic polymer binder is 8%; the mass percentage of the organic solvent 59%; La 0.6 Ca 0.4 FeO 3-δ The content of ceramic powder is 31.04%; the content of dispersant is 1%; the mass percentage of stainless steel powder is 0.96%; the obtained casting solution is vacuum degassed for 1 h, and then moved to the spinning equipment tank, under nitrogen pressure, with pure Water is the core liquid, and the casting liquid is pressed into the gel bath water through the spinning head...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com