Forced vibrating air-sucking directional pollination device for hybrid rice

A hybrid rice and pollination device technology, applied in the field of agricultural machinery, can solve the problems of short flowering time and pollen life, easy to miss the best time for pollination, high labor intensity, etc., and achieve good pollination quality, high pollination efficiency, and labor intensity. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below with reference to the drawings and examples.

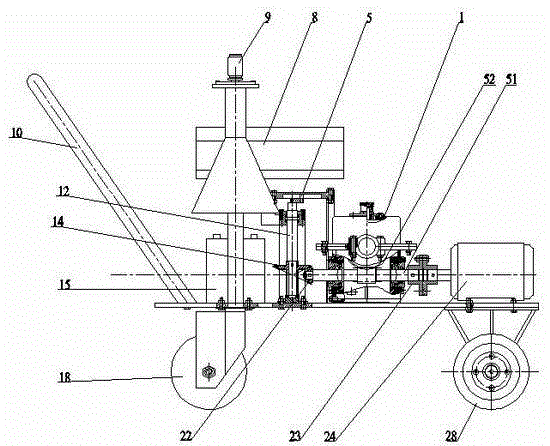

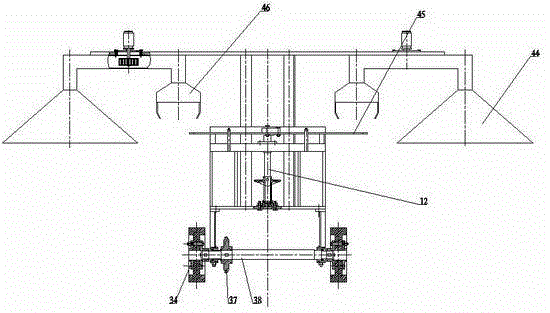

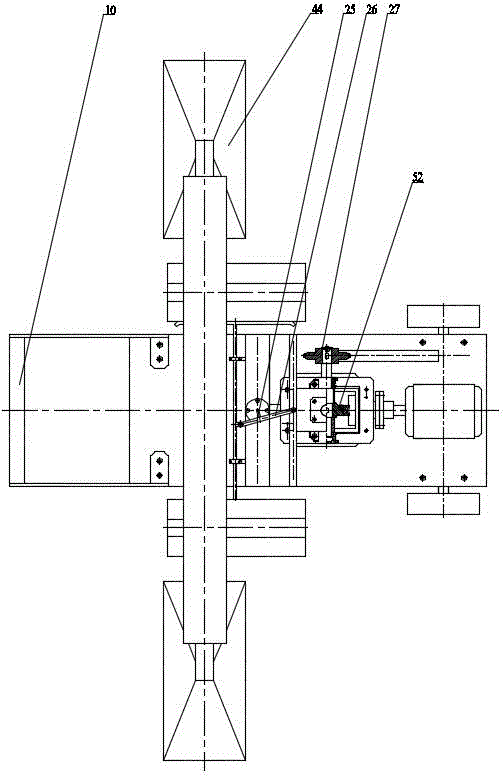

[0019] Such as figure 1 , 2 3, the stress-vibration type hybrid rice suction directional pollination device of this embodiment mainly includes two parts: a transmission mechanism and a pollination mechanism. Pollination institutions include Danghe institutions and dusting institutions.

[0020] The transmission mechanism is driven by a motor 24, which can be a 500w DC motor with a rated speed of 500r / min. It is powered by battery 15.

[0021] The motor 24 is connected to a worm gear reducer 1 to adjust the speed. The worm gear reducer 1 includes a worm 51 and a worm gear 52. One end of the worm 51 is connected to the drive shaft of the motor 24 through the motor coupling 23, and the other end is connected to the small bevel gear 22. Worm gear 52 is connected to main sprocket 27 (such as image 3 ), the main sprocket 27 is connected to the slave sprocket 37 through a chain, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com