Wiring method of power unit and transformer in high-voltage frequency converter and high-voltage frequency converter

A high-voltage inverter and power unit technology, applied in the field of high-voltage inverters, can solve the problems of excessively long cable length, difficult length control, and increased cable cost, and achieve the effects of improving assembly efficiency, shortening production cycle, and reducing cable cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

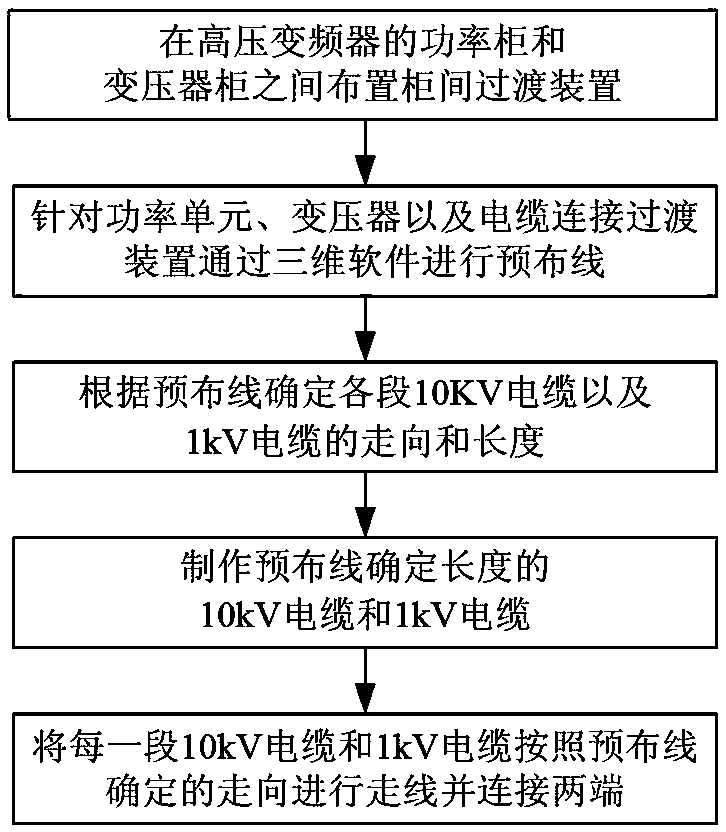

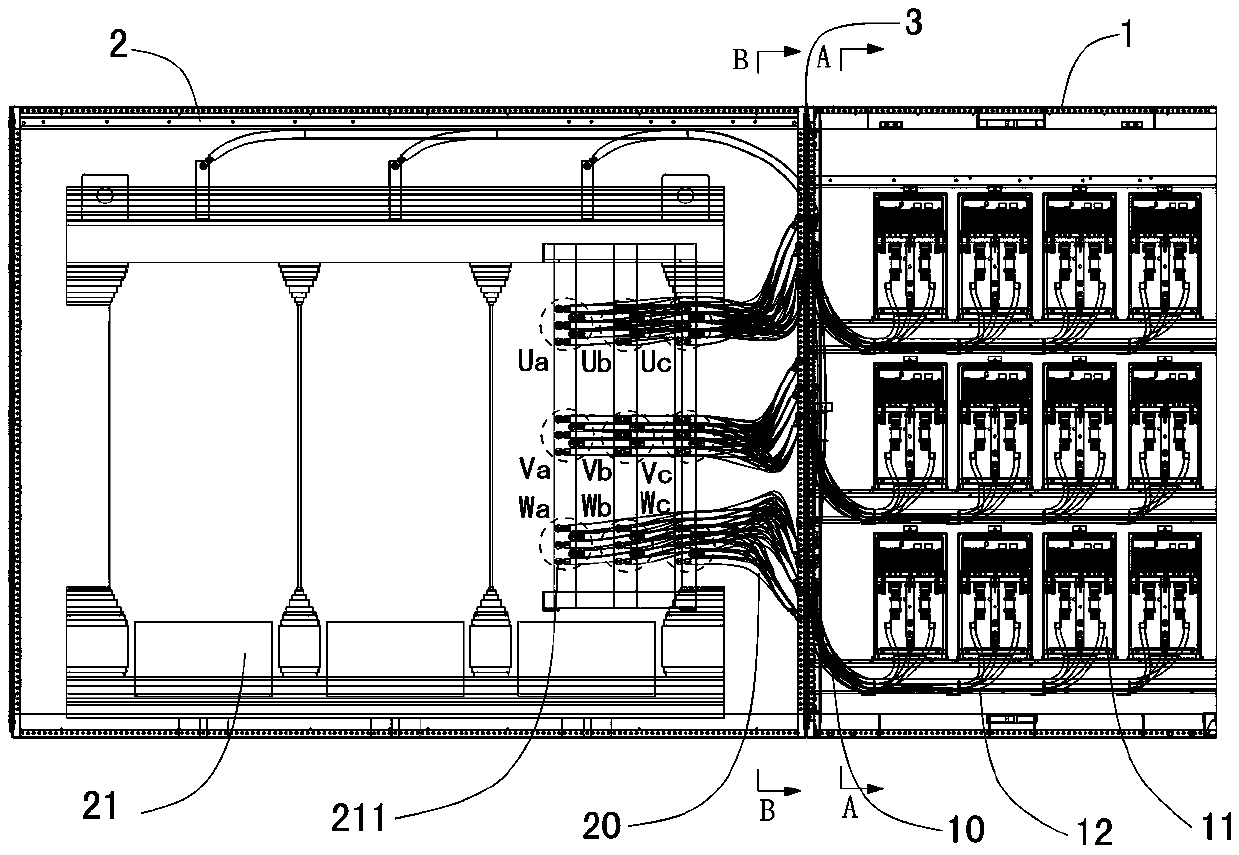

[0032] Such as figure 1 As shown, the wiring method steps of the power unit and the transformer in the high-voltage frequency converter of this embodiment include:

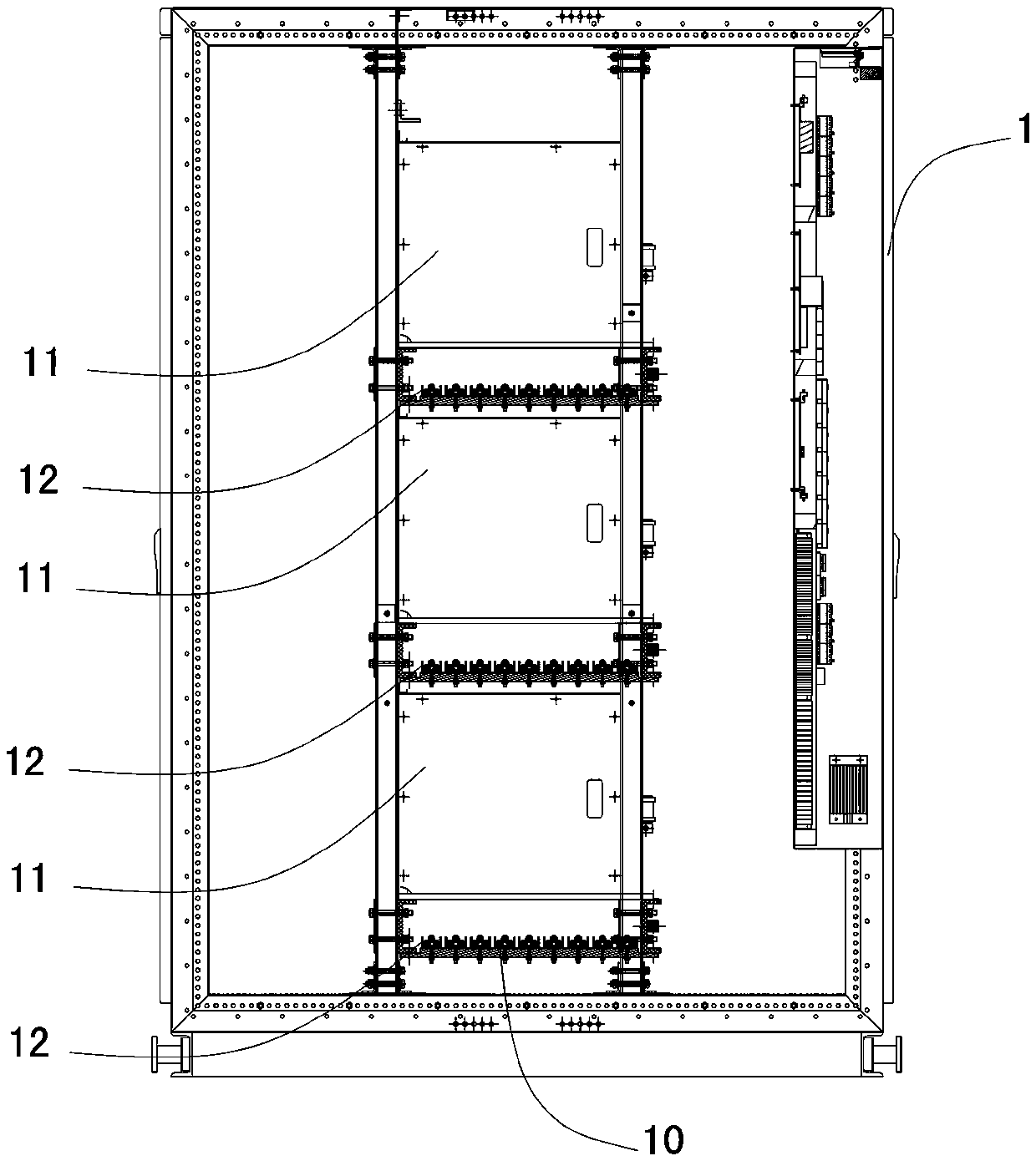

[0033] 1) The inter-cabinet transition device is arranged between the power cabinet and the transformer cabinet of the high-voltage frequency converter. Both sides of the inter-cabinet transition device are provided with connecting bolts for the electrical connection between the power unit and the transformer;

[0034] 2) For the power unit, transformer and cable connection transition device, use 3D software to perform pre-wiring to simulate the routing path of each cable, and when using 3-D software to perform pre-wiring, connect the connecting bolts of the inter-cabinet transition device Use 10kV cables between the terminals, use 1kV cables between the connecting bolts of the inter-cabinet transition device and the connecting terminals of the power unit, and keep a safe distance between the 1kV cables of adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com