Gluing station

A technology of glue table and lift table, applied in the field of glue table, can solve the problems of inaccurate control of glue position and length, and achieve the effects of high reliability, high glue quality and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

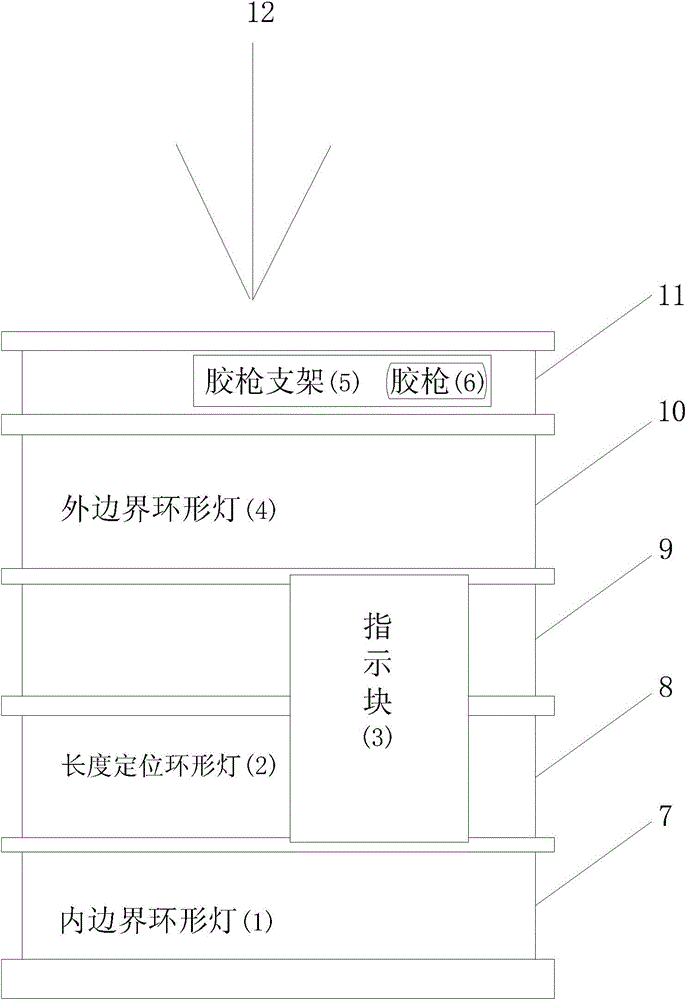

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

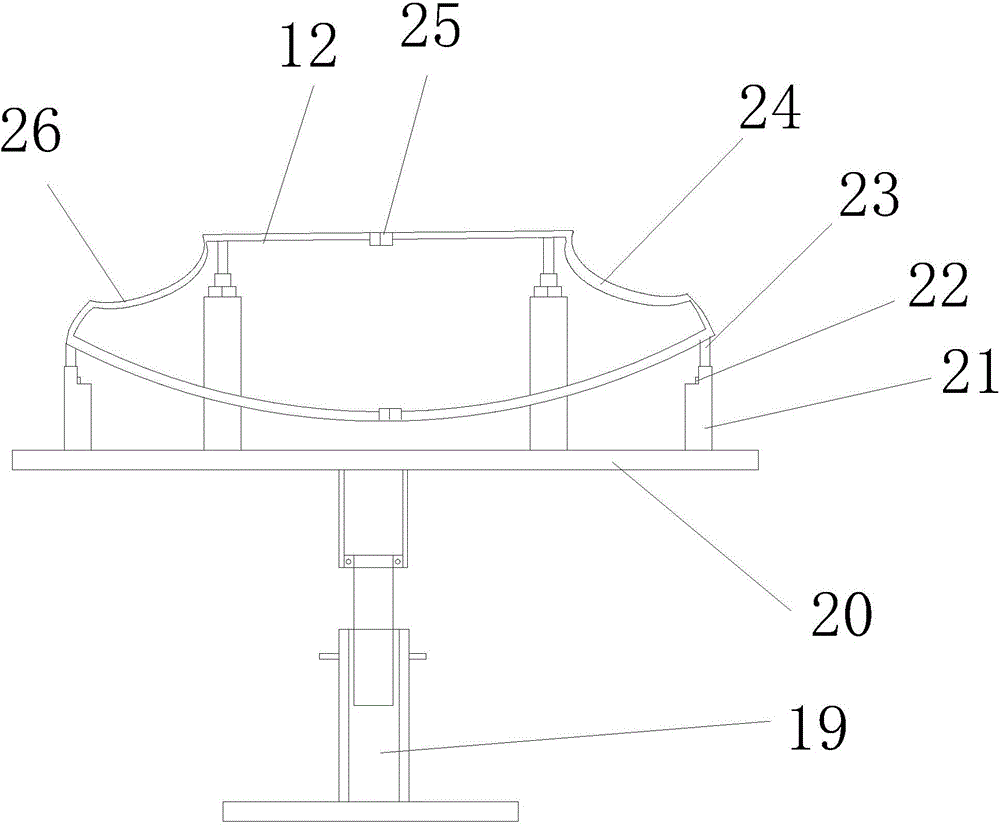

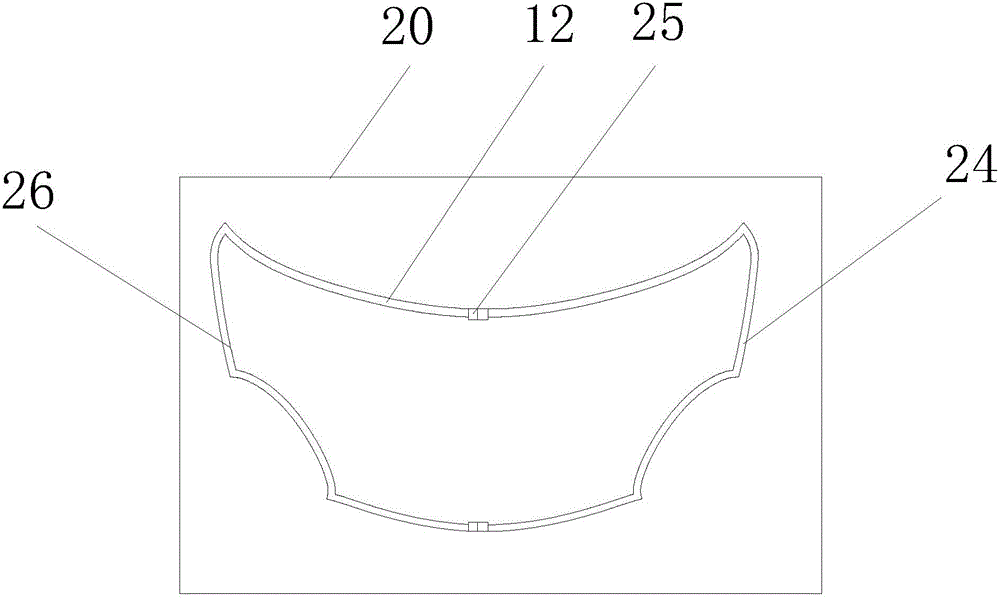

[0023] An example of a gluing table, such as figure 1 , figure 2 As shown, it includes a rotary lifting platform 19, an annular ring 12 that is similar to the outer ring of the parts 27 that need to be glued and is proportionally reduced to one-half to one-fifth. A plurality of support rods 21 are arranged on the table top 20 of the rotary lifting platform, and a positioning block 22 is arranged on the outer top of each support rod. The annular ring is made up of a left half circle 26 and a right half circle 24, and the left half circle and the right half circle are turned over and connected by a hinge 25, and the maximum angle at which the right half circle is turned over relative to the left half circle is 90 degrees. A positioning foot 23 matching the positioning block is provided on the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com