A tapering method for chalcogenide glass optical fiber

A technology of chalcogenide glass and optical fiber, which is applied in the field of tapering of optical fiber, which can solve the problems of unsuitable drawing, uneven tapered area, bending deformation of optical fiber, etc., and achieve less internal stress and structural defects, high structural uniformity, and good The effect of the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: with Ge 30 As 10 Se 30 Te 30 The chalcogenide glass suspension core fiber is used as a tapered parent fiber, and a tapered fiber with a tapered region length of about 2 cm and a tapered waist outer diameter of about 1000 nm is made. 30 As 10 Se 30 Te 30 The taper method of chalcogenide glass optical fiber comprises the following steps:

[0022] 1) Prepare a 15 m long, 500 um outer diameter Ge 30 As 10 Se 30 Te 30 A chalcogenide glass three-hole suspension core optical fiber is used as the mother fiber 1, a plastic hose 2 with a length of about 4 cm, and a steel metal plate 3 with a scale line of 0.5 m in length, 0.02 m in width, and 0.001 m in thickness. Wash and dry the metal plate 3 with distilled water;

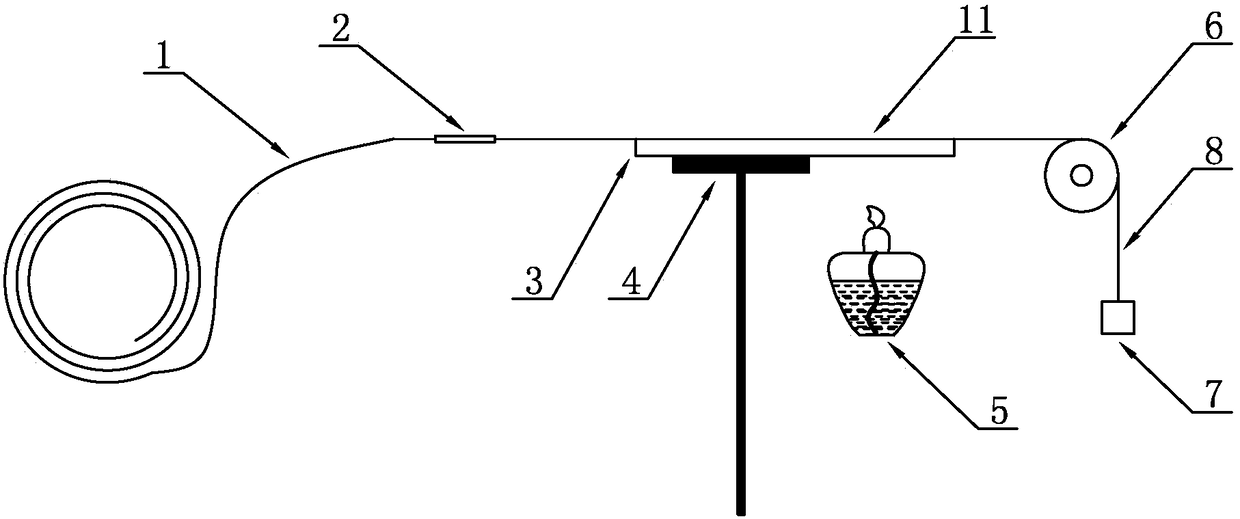

[0023] 2) if figure 1As shown, the metal plate 3 is horizontally fixed on a frame 4, so that both ends of the metal plate 3 are suspended in the air, and the front end exposes a 10 cm suspended area, and a certain pulley 6 is fixed in front...

Embodiment 2

[0026] Example 2: As with no organic coating layer 2 S 3 The bare chalcogenide glass fiber is used as the tapered parent fiber to make a tapered optical fiber with a tapered region length of about 5 cm and a tapered waist outer diameter of about 1500 nm. The As 2 S 3 The taper method of chalcogenide glass optical fiber comprises the following steps:

[0027] 1) Prepare a 20 m long, 800 um outer diameter As 2 S 3 A chalcogenide glass three-hole suspension core optical fiber is used as the mother fiber 1, a plastic hose 2 with a length of about 7 cm, and a steel metal plate 3 with a scale line of 0.5 m in length, 0.02 m in width, and 0.001 m in thickness. Wash and dry the metal plate 3 with distilled water;

[0028] 2) if figure 1 As shown, the metal plate 3 is horizontally fixed on a frame 4, so that both ends of the metal plate 3 are suspended in the air, and the front end exposes a 10 cm suspended area, and a certain pulley 6 is fixed in front of the metal plate 3; dete...

Embodiment 3

[0031] Embodiment 3: with As 2 S 3 The chalcogenide glass standard optical fiber is used as the tapered parent fiber, and the tapered optical fiber with the length of the tapered region about 1 cm and the outer diameter of the tapered waist is about 800 nm. The As 2 S 3 The taper method of chalcogenide glass optical fiber comprises the following steps:

[0032] 1) Prepare a 20 m long, 200 um outer diameter As 2 S 3 The chalcogenide glass optical fiber is used as the mother fiber 1, a plastic hose 2 about 3 cm in length, a steel metal plate 3 with a scale line of 0.5 m in length, 0.02 m in width, and 0.001 m in thickness. 3 wash and dry;

[0033] 2) see figure 1 , fix the metal plate 3 horizontally on a frame 4, so that both ends of the metal plate 3 are suspended in the air, and the front end exposes a 10 cm suspended area; determine the area 11 to be tapered on the mother fiber 1, and put 2 sets of plastic hoses On the mother fiber 1, move the plastic hose 2 to the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com