Liquid metal cooling pool type reactor multifunctional in-reactor heat separation system

A liquid metal cooling and reactor technology, applied in reactors, cooling devices, nuclear power generation, etc., can solve problems such as narrow application range, complex system structure, and inconvenient maintenance, and achieve wide applicability, simple system structure, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

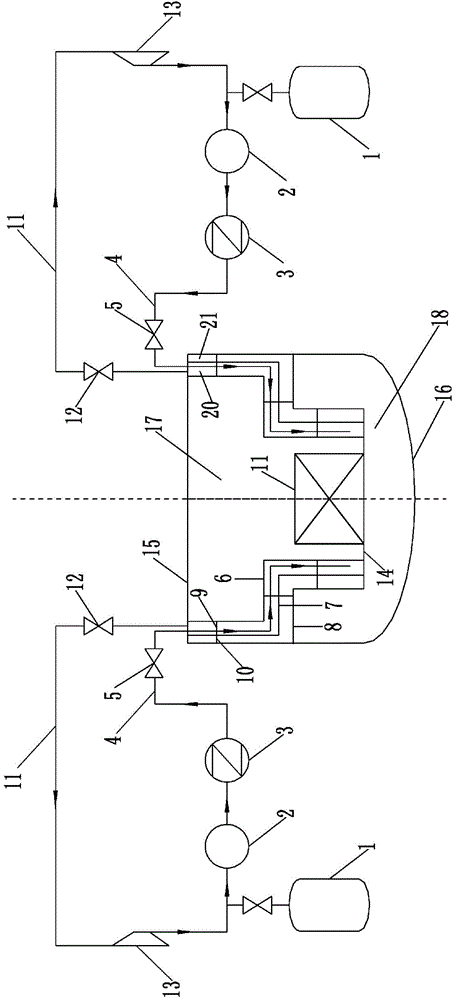

[0030] Taking the multifunctional in-reactor thermal separation system designed for a lead-bismuth cooled natural circulation pool reactor as an example, the main technical parameters and related operating conditions of the system are described below.

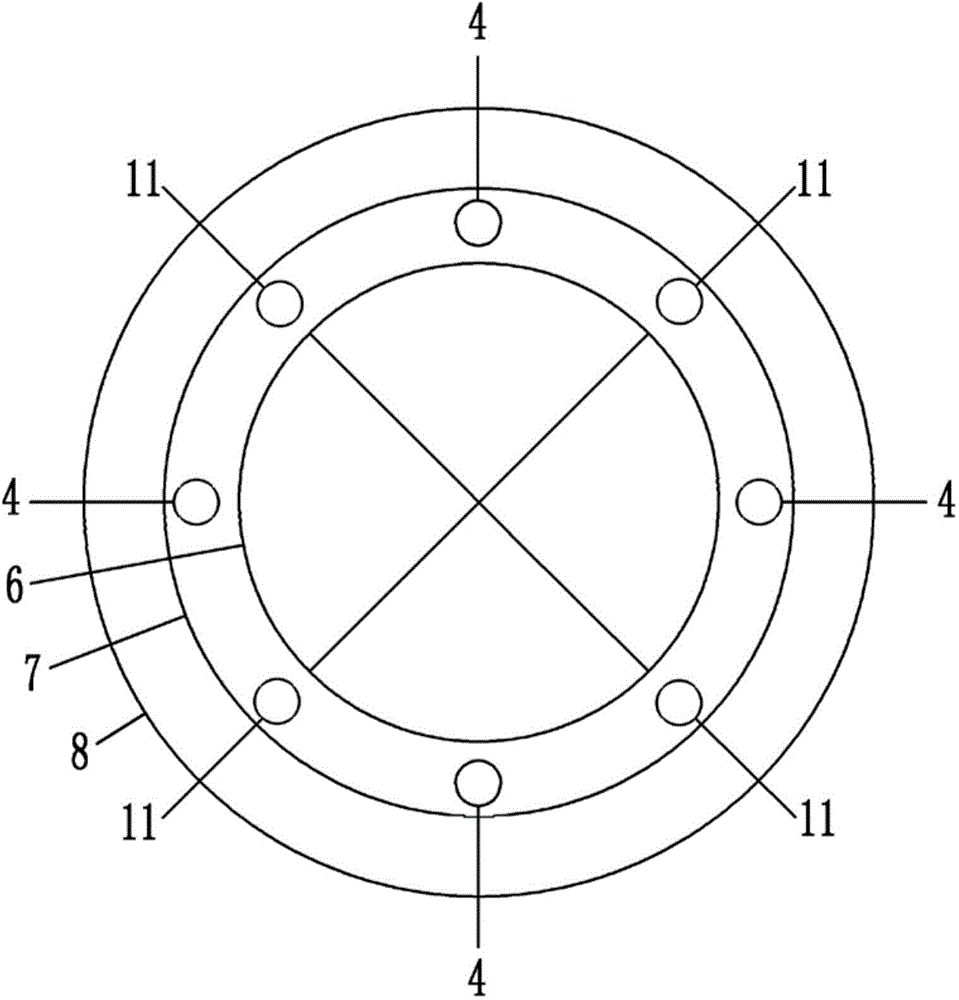

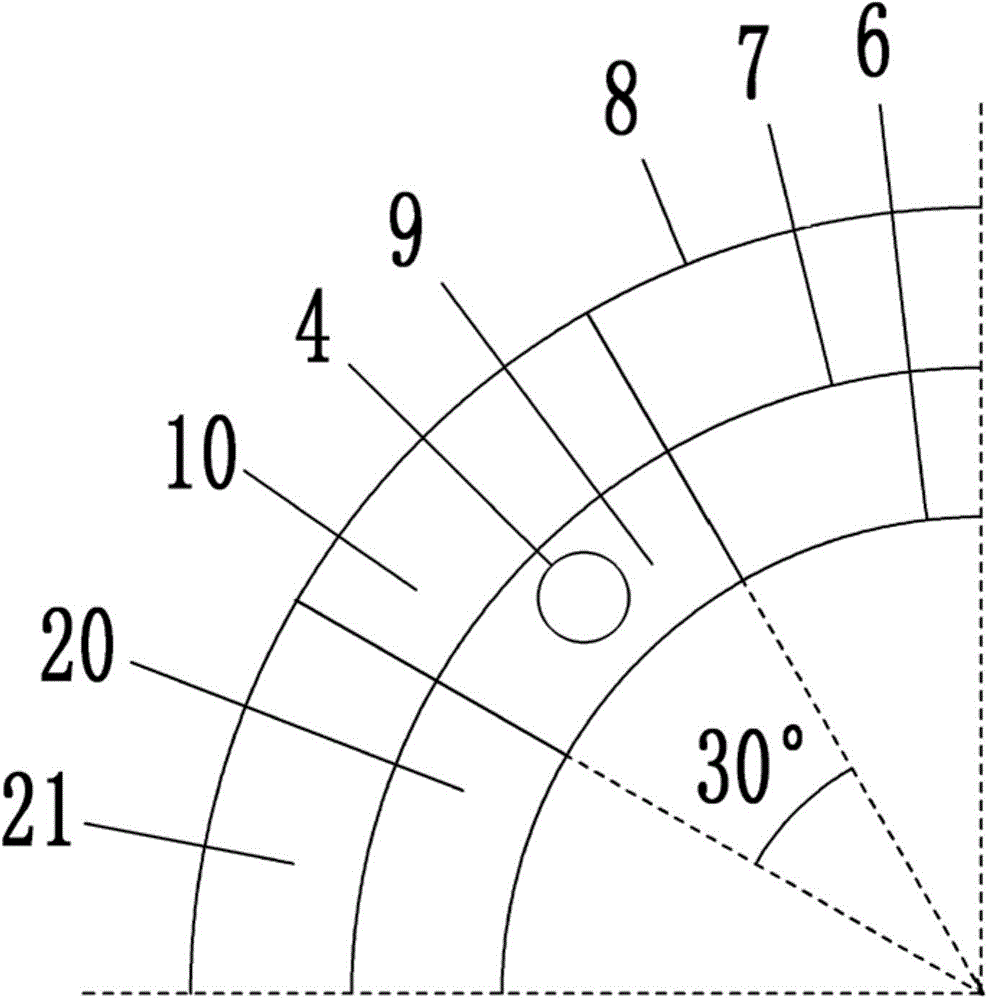

[0031] The rated thermal power of the whole reactor is 10MW, the liquid lead bismuth (LBE) in the main container 16 is about 550t, and the melting point of lead bismuth is 125°C. The designed liquid heavy metal cooling natural circulation reactor multi-function thermal separation system in the reactor consists of a gas storage tank 1, a gas filter 2, a gas heater 3, a gas input pipe 4, an intake valve 5, and an inner thermal barrier 6 , middle thermal partition 7, outer thermal partition 8, inner partition fixed steel plate 9, outer partition fixed steel plate 10, gas output pipe 11, exhaust valve 12, air extractor 13 and between equipment connected pipes and valves. The static connection mode of relevant components and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com