Industrial process fault diagnosis method based on switching linear dynamic system model

A technology of dynamic system model and fault diagnosis, which is applied in general control system, control/adjustment system, test/monitoring control system, etc., can solve the problem of not being able to meet the actual industrial process monitoring requirements, unfavorable for the implementation of industrial process automation, and unable to achieve satisfactory monitoring Effect and other issues, to achieve the effect that is conducive to the implementation of automation, improve the effect of fault diagnosis, and enhance the mastery of process status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

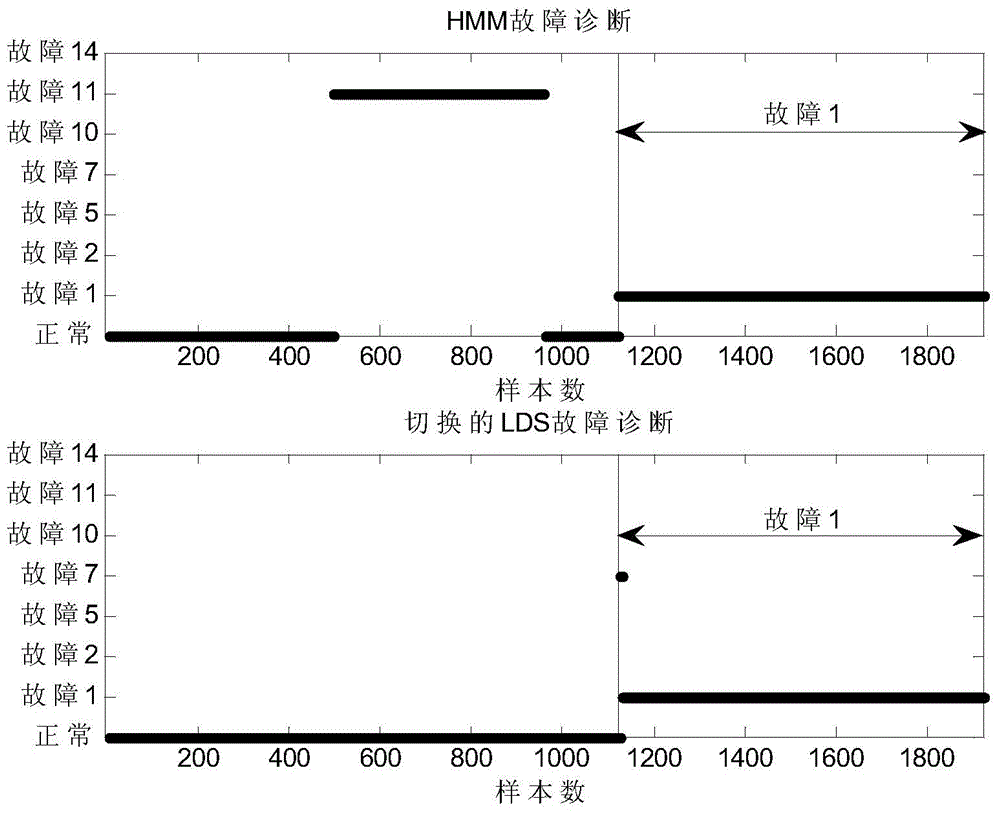

[0017] The invention provides an industrial process fault diagnosis method based on switching linear dynamic system model. The method aims at the problem of industrial process fault diagnosis. Firstly, the distributed control system is used to collect the data of normal working Data of fault conditions, and classify them into categories of conditions. Then the linear dynamic system model is established for different working condition categories, and then the switched linear dynamic system model is established. Store the model parameters in the database for later use. When monitoring and diagnosing new online data, first use Gaussian and filtering methods to obtain the posterior probability of the data under various working conditions, and then obtain the fault diagnosis results.

[0018] The main steps of the technical solution adopted in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com