Wood-plastic plate and preparation method thereof

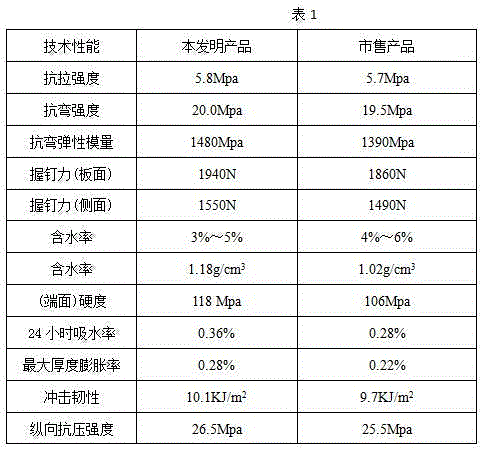

A wood-plastic board and board technology, applied in the field of building materials, can solve the problems of high water expansion rate, poor screw holding force, and large glue content, etc., to achieve improved adhesion, improved use performance, and strong hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1—Preparation of straw three-layer composite board

[0033] A. Straw pretreatment

[0034] After the straw is cleaned and removed, cut it into 0.5cm long pieces; weigh NaOH and dissolve it in water to form a 1% alkali solution; add the straw to the alkali solution, and the mass ratio of the straw to the alkali solution is 1:10; heat to 100°C, soak for 1 hour, filter to obtain straw powder, wash with water until the water becomes neutral, dry, and set aside.

[0035] B. Preparation of single-layer straw composite board

[0036] 1. Put 80kg of carboxymethyl starch into the drum for pre-gelatinization and drying to obtain pre-gelatinized carboxymethyl starch, transfer it to a high-speed mixer, add glycerin accounting for 30% of the mass of carboxymethyl starch, add glycerin in three times, every ten Add once every minute; mix evenly at a temperature of 50°C, and let it stand for 6 hours to obtain glycerin plasticized carboxymethyl starch;

[0037] 2. Dry polylac...

Embodiment 2

[0043] Example 2—Preparation of a single-layer straw composite board

[0044] A. Straw pretreatment

[0045] After cleaning and removing impurities, the straw is cut into 1cm-long pieces, weighed and dissolved in water to form a 2% alkali solution, and the straw is added to the alkali solution with a mass ratio of the straw to the alkali solution of 1:10, heated to Soak at 90°C for 2 hours, filter to obtain straw coarse powder, wash with water until the water becomes neutral, dry, and set aside.

[0046] B. Preparation of single-layer straw composite board (composite board A)

[0047] 1. Take 120kg of carboxymethyl starch and put it into the drum for pre-gelatinization and drying to obtain pre-gelatinized carboxymethyl starch, transfer it to a high-speed mixer, add glycerin accounting for 35% of the mass of carboxymethyl starch, add glycerin in three times, every ten Minutes are added once. Mix well at 45°C and let stand for 5h. Obtain glycerol plasticized carboxymethyl st...

Embodiment 3

[0051] Example 3—Preparation of a single-layer straw composite board

[0052] A. Straw pretreatment

[0053] After the straw is cleaned and removed, cut it into 0.75cm long pieces, weigh NaOH and dissolve it in water to form a 3% alkali solution, add the straw to the alkali solution, the mass ratio of the straw to the alkali solution is 1:10, heat Soak at 80°C for 2 hours, filter to obtain straw coarse powder, wash with water until the water becomes neutral, dry, and set aside.

[0054] B. Preparation of single-layer straw composite board (composite board A)

[0055] 1. Take 100kg of carboxymethyl starch and place it into a roller for pregelatinization and drying to obtain pregelatinized carboxymethyl starch. Transfer it to a high-speed mixer and add glycerin accounting for 40% of the mass of carboxymethyl starch. Glycerin is added in three times, every ten Minutes are added once. Mix well at 40°C and let stand for 4h. Obtain glycerol plasticized carboxymethyl starch;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com