Cyclopropane alpha-amino acid derivatives containing continuous quaternary carbon center and synthesis method thereof

A synthesis method and cyclopropane technology are applied in the field of cyclopropane α-amino acid derivatives and synthesis fields containing continuous quaternary carbon centers, which can solve the problems of high cost, narrow substrate application range, high toxicity, etc. The effect of good enantioselectivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

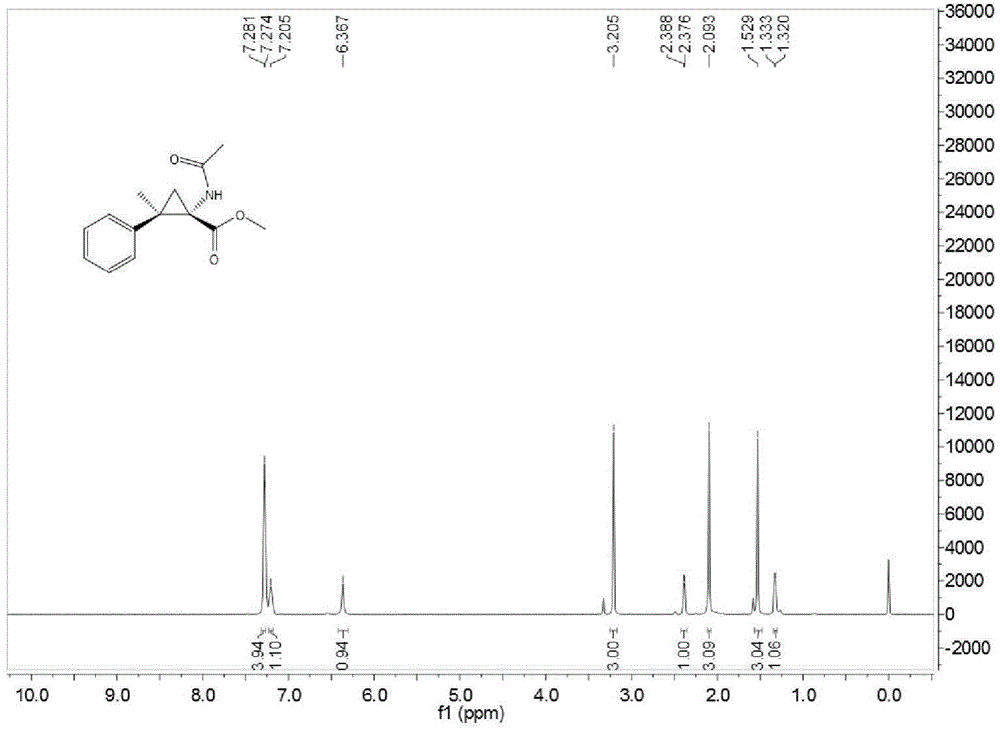

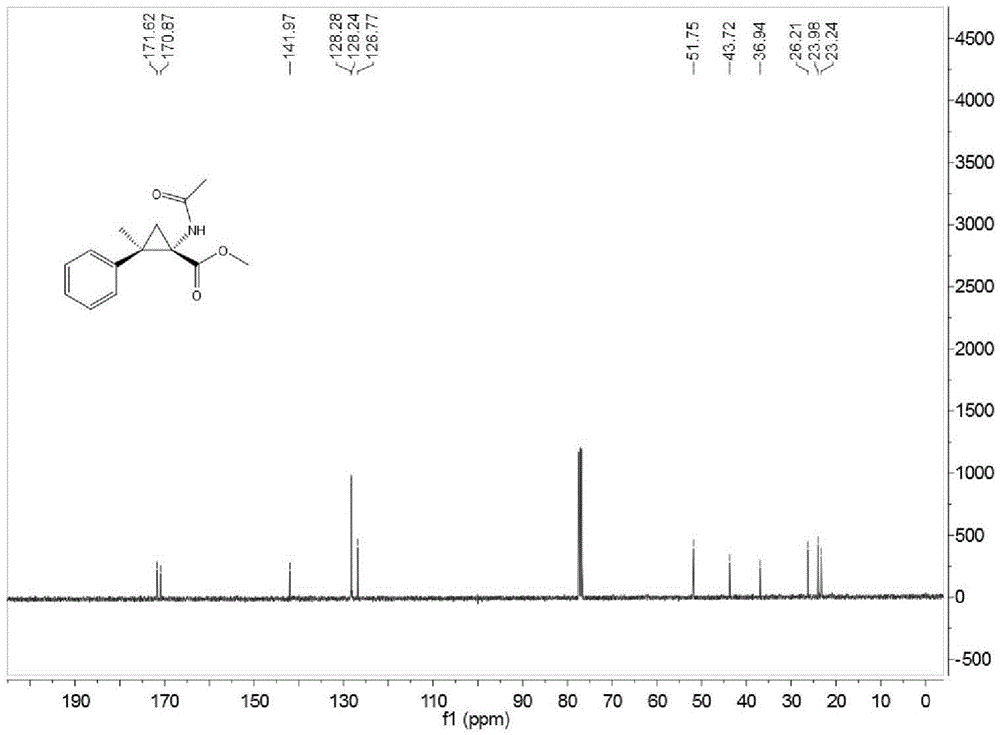

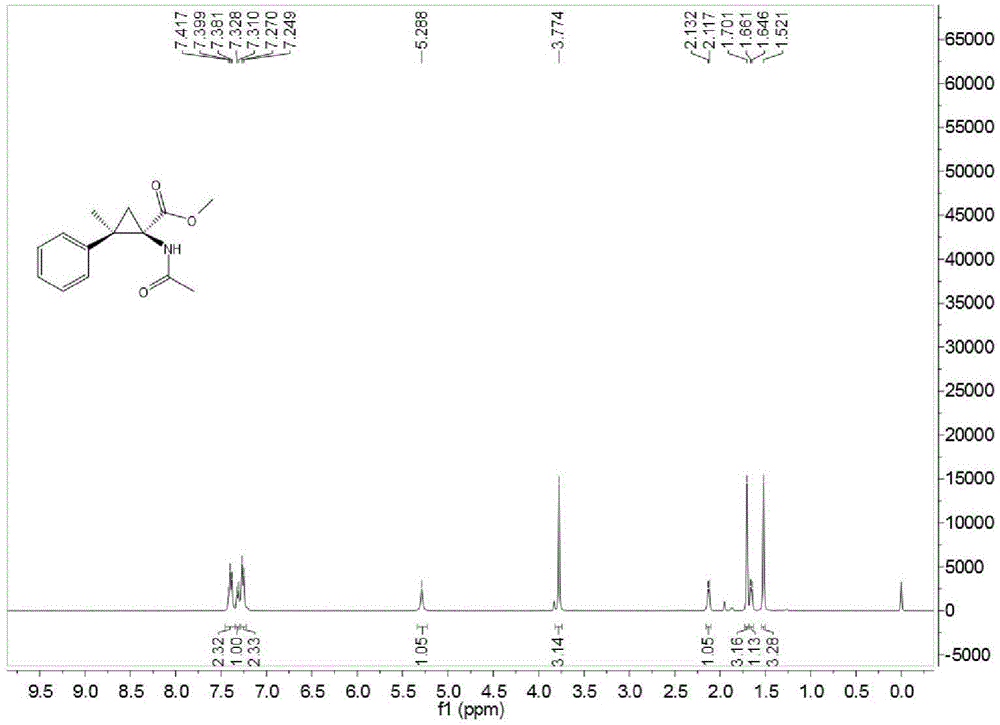

[0029] In a 25ml reaction flask equipped with a reflux condenser, add 0.2mmol of acetophenone p-toluenesulfonylhydrazone, 0.2mmol of cesium carbonate, 0.02mmol of benzyltriethylammonium chloride, 2ml of toluene, at 25°C After stirring and reacting for 1 hour, 0.1 mmol of methyl 2-acetamidoacrylate was added, and the reaction system was stirred and reacted at 90° C. for 12 hours, then heating and stirring were stopped, and cooled to room temperature. The reaction solution was extracted with ethyl acetate, the solvent was removed by rotary evaporation under reduced pressure, and then separated and purified by column chromatography to obtain the target product. The column chromatography eluent used was a mixed solvent of petroleum ether:ethyl acetate with a volume ratio of 2:1 , the main diastereomer of the product was obtained with a yield of 82%.

Embodiment 2

[0031] In a 25ml reaction flask equipped with a reflux condenser, add 0.2mmol of acetophenone p-toluenesulfonylhydrazone, 0.2mmol of potassium carbonate, 0.02mmol of benzyltriethylammonium chloride, 2ml of toluene, at 25°C After stirring and reacting for 1 hour, 0.1 mmol of methyl 2-acetamidoacrylate was added, and the reaction system was stirred and reacted at 90° C. for 12 hours, then heating and stirring were stopped, and cooled to room temperature. The reaction solution was extracted with ethyl acetate, the solvent was removed by rotary evaporation under reduced pressure, and then separated and purified by column chromatography to obtain the target product. The column chromatography eluent used was a mixed solvent of petroleum ether:ethyl acetate with a volume ratio of 2:1 , the main diastereoisomer of the product was obtained with a yield of 63%.

Embodiment 3

[0033] In a 25 ml reaction flask equipped with a reflux condenser, add 0.2 mmol of acetophenone-p-toluenesulfonylhydrazone, 0.2 mmol of potassium tert-butoxide, 0.02 mmol of benzyltriethylammonium chloride, and 2 ml of toluene. After stirring and reacting at 25°C for 1 hour, 0.1 mmol of methyl 2-acetamidoacrylate was added, and the reaction system was stirred and reacted at 90°C for 12 hours, then heating and stirring were stopped, and cooled to room temperature. The reaction solution was extracted with ethyl acetate, the solvent was removed by rotary evaporation under reduced pressure, and then separated and purified by column chromatography to obtain the target product. The column chromatography eluent used was a mixed solvent of petroleum ether:ethyl acetate with a volume ratio of 2:1 , the main diastereoisomer of the product was obtained with a yield of 57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com