Anaerobic digestion sludge conditioning system and method

An anaerobic digestion system and anaerobic digestion technology, applied in the field of solid waste treatment, can solve the problems of consuming large energy and increasing temperature, and achieve the effect of reducing energy consumption, realizing reduction and improving anaerobic digestion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

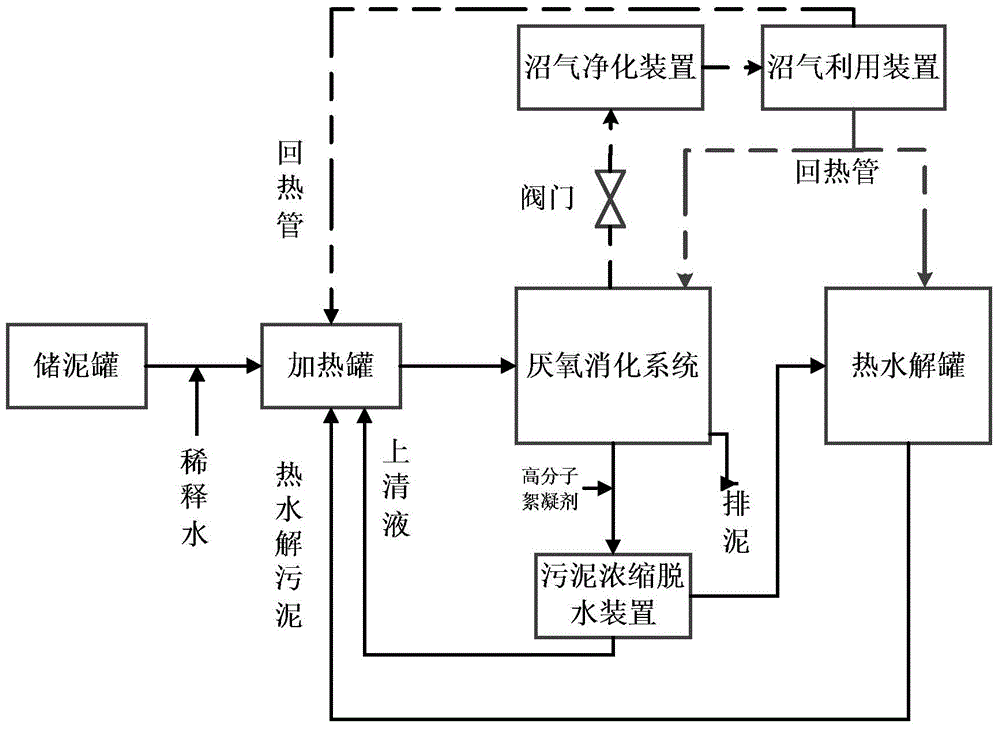

Method used

Image

Examples

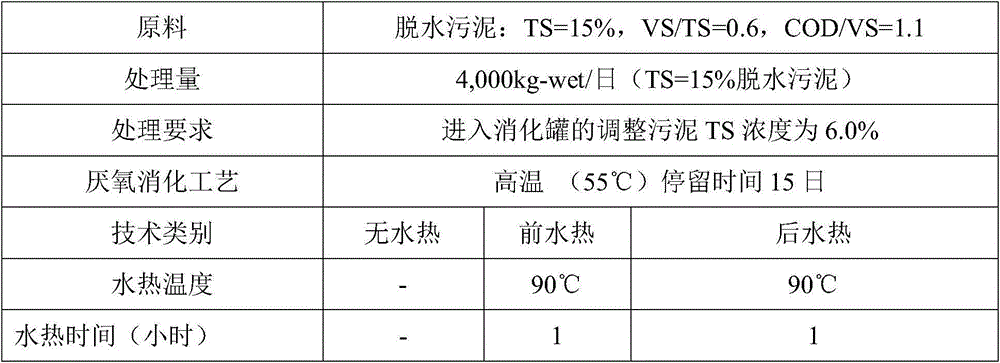

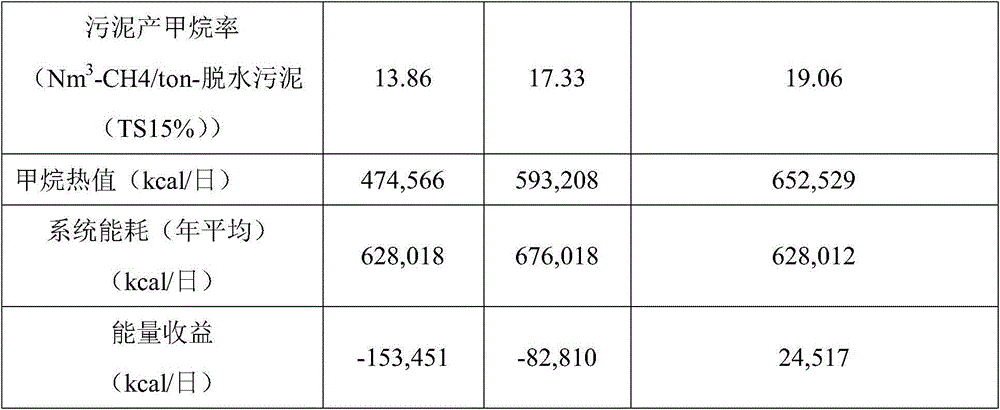

Embodiment 1

[0034] The solid content (TS) of the dewatered sludge of the urban sewage treatment plant: 15%, first diluted with water and pumped into the heating tank through the sludge pump, in the heating tank with the returned sludge after thermal hydrolysis treatment (TS: 20 %) mixed and warmed up to 55°C, before entering the anaerobic digestion system, adjust the TS to 6% with the reflux supernatant (TS: 2.5%) of the concentrated dehydration of the digestive liquid, and the residence time of the sludge in the anaerobic digestion system is On the 15th, the methane content in the gas production was 55%, and the methane production rate of the sludge was 19.06Nm 3 -CH 4 / ton- dewatered sludge, the amount of sludge discharged by the anaerobic digestion system is 56% of the amount of sludge input, the discharged digestive liquid is added with polymer flocculant for concentration and dehydration, and 80% of the separated supernatant is refluxed and adjusted For the water content of the feed...

Embodiment 2

[0040] The solid content (TS) of the dewatered sludge of the urban sewage treatment plant: 15%, first diluted with water and pumped into the heating tank through the sludge pump, in the heating tank with the returned sludge after thermal hydrolysis treatment (TS: 20 %) mixed and warmed up to 35°C, before entering the anaerobic digestion system, adjust the TS to 6% with the reflux supernatant (TS: 2.5%) of the concentrated dehydration of the digestive liquid, and the residence time of the sludge in the anaerobic digestion system is On the 30th, the methane content in the gas production was 55%, and the methane production rate of the sludge was 17.33Nm 3 -CH 4 / ton- dewatered sludge, the amount of sludge discharged by the anaerobic digestion system is 56% of the amount of sludge input, the discharged digestive liquid is added with polymer flocculant for concentration and dehydration, and 80% of the separated supernatant is refluxed and adjusted For the water content of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com