Chili oil and preparation method thereof

A technology of chili oil and chili, which is applied in the field of seasoning food, can solve the problems of general quality of seasoning sauce, lack of fragrance and color, dryness and spicyness, etc., and achieve the effect of shortening storage time, spicy and soft, and complete color and fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

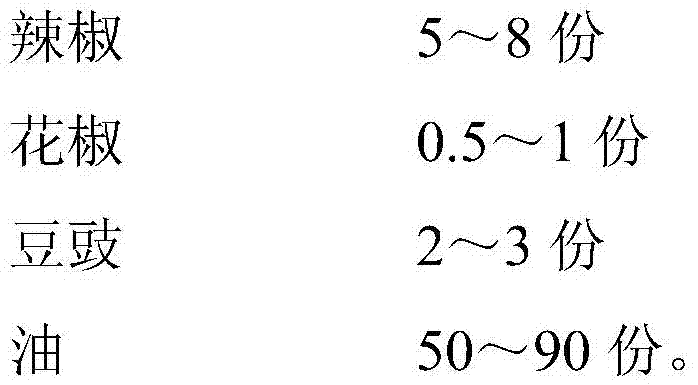

[0028] The present invention also provides a kind of preparation method of capsicum oil, and this preparation method comprises the following steps:

[0029] Pre-treatment: wash 5-8 parts of dried chili, put it in a pot and add water to heat, keep the water slightly boiled for 10-15 minutes, take out and drain the water and grind the dried chili;

[0030] Dried chili is made by dehydrating and drying fresh red chili. It is characterized by low water content and is suitable for long-term storage. However, if the dried chili is not processed before frying or the processing is too simple, it will easily give people a dry and spicy feeling. The taste is uncomfortable, and it will easily be fried or burnt during the frying process, which will make the color of the product poor. The present invention screens dried chilies with 5 to 8 parts by weight and cleans them with clear water, then puts the cleaned dried chilis into a pot and adds water with a mass of 3 to 5 times that of the d...

Embodiment 1

[0038] Pre-treatment: sieve dried chilies with 5 parts by weight, and clean them with clear water, then put the cleaned dried chilis into a pot and add water with 3 times the quality of dried chilis in the pot, heat it when the water boils slightly After maintaining for 12 minutes, take out the dried chili and drain the water, and finally use a meat grinder to grind the dried chili for subsequent use, preferably the dried chili is crushed into 13 mesh chili powder; in the present embodiment, the quality of the dried chili is 5kg, and the water The mass is 15kg.

[0039]Frying: Add 50 parts by weight of peanut oil into the frying pan, heat it until the oil temperature reaches 115°C, add 0.8 parts of Chinese prickly ash and fry for 20 minutes, so that the aroma of Chinese prickly ash is fried, and then add 2 parts of fermented soybeans Fry for 8 minutes to make the fermented soy sauce flat out, and finally add 5 parts by weight of ground 13-mesh chili powder and fry for 15 minut...

Embodiment 2

[0042] Pre-treatment: sieve dried chilies with 7 parts by weight, and clean them with water, then put the cleaned dried chilis into a pot and add water with 5 times the quality of dried chilis in the pot, heat it when the water boils slightly After maintaining for 15 minutes, take out the dried chili and drain the water, and finally use a meat grinder to grind the dried chili for subsequent use, preferably the dried chili is crushed into 14 mesh chili powder; in the present embodiment, the quality of the dried chili is 7kg, and the water The mass is 35kg.

[0043] Frying: Add 80 parts by weight of peanut oil into the frying pan, heat it until the oil temperature reaches 120°C, add 0.5 parts of Chinese prickly ash and fry for 25 minutes, so that the aroma of Chinese prickly ash is fried, and then add 2.5 parts of fermented soybeans Fry for 5 minutes to make the fermented soy sauce flat and fragrant, and finally add 7 parts by weight of ground 14-mesh chili powder and fry for 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com