A closed focal plane box for a space camera

A technology of space camera and focal plane box, which is applied in the direction of camera, camera body, TV, etc., can solve the problems of bulky, easy to enter dust and other debris, debris pollution, etc., to reduce the weight of the camera and meet the sealing requirements , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

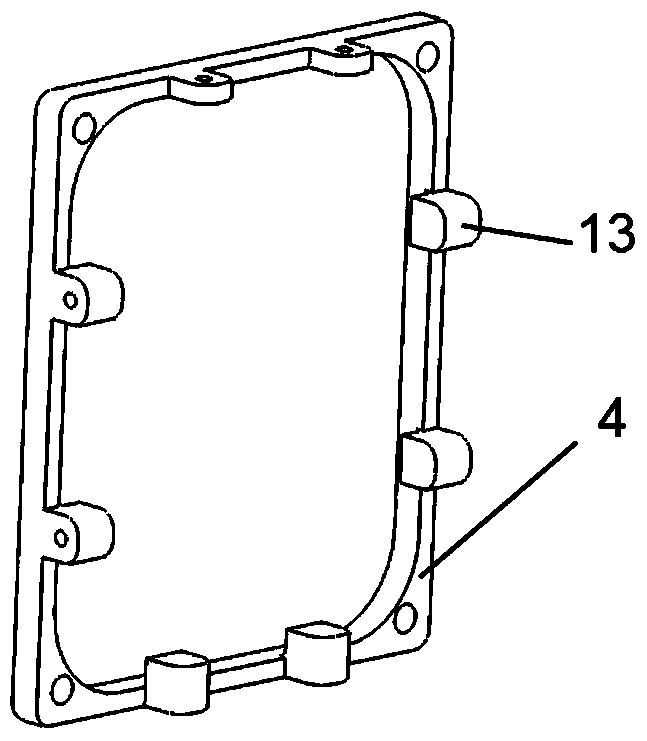

[0031] The focal plane trimming pads are located between the front panel and the focal plane circuit board, and the four focal plane trimming pads are respectively located at the four corners of the focal plane circuit board. The focal plane trimming pad is made of heat insulating material, which can not only trim the perpendicularity between the focal plane and the optical axis, but also isolate the heat from the front panel from being transmitted to the focal plane circuit board.

Embodiment 2

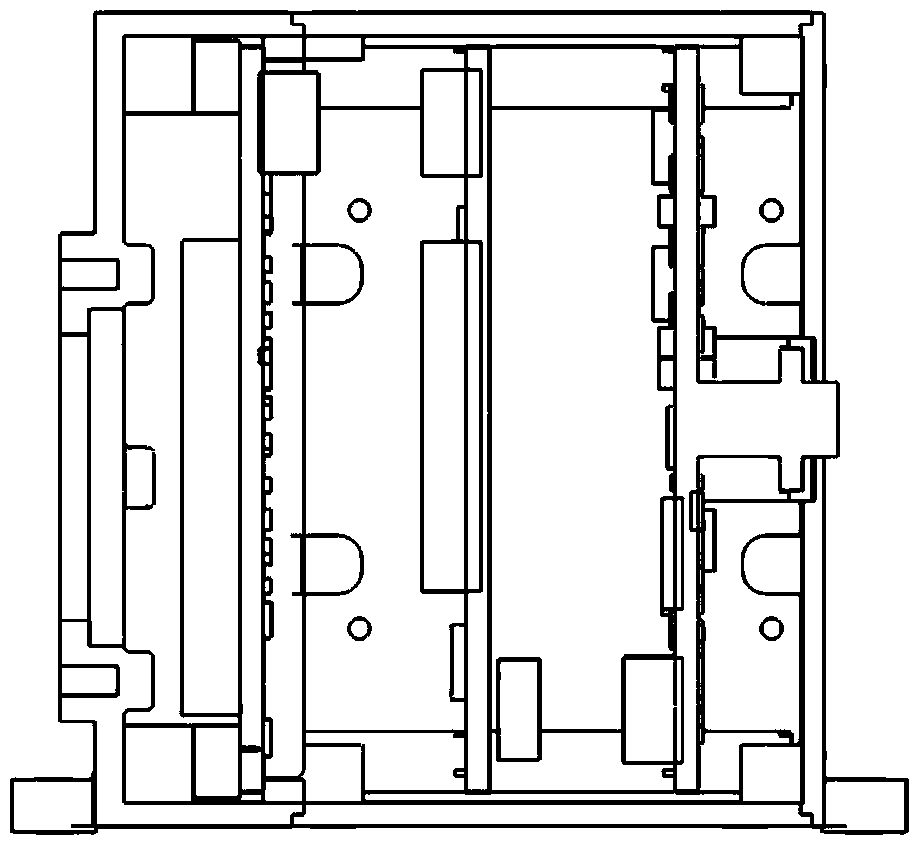

[0033] The focal plane box adopts the focal plane metal sealing pressure ring to divide the entire focal plane box into front and back two subspaces, the focal plane circuit board 3 is installed in the front cavity, and other circuit boards are installed in the rear space, and the circuit boards are connected by connectors. The front cavity is sealed by a metal sealing pressure ring and lens flange, and all mounting screw holes are blind holes, which effectively guarantees that there will be no foreign matter inside the focal plane box. The metal sealing pressure ring is closely matched with the surroundings of the front panel, and the end face is pressed to the focal plane circuit board, while ensuring an effective and safe distance from the components on the circuit board.

Embodiment 3

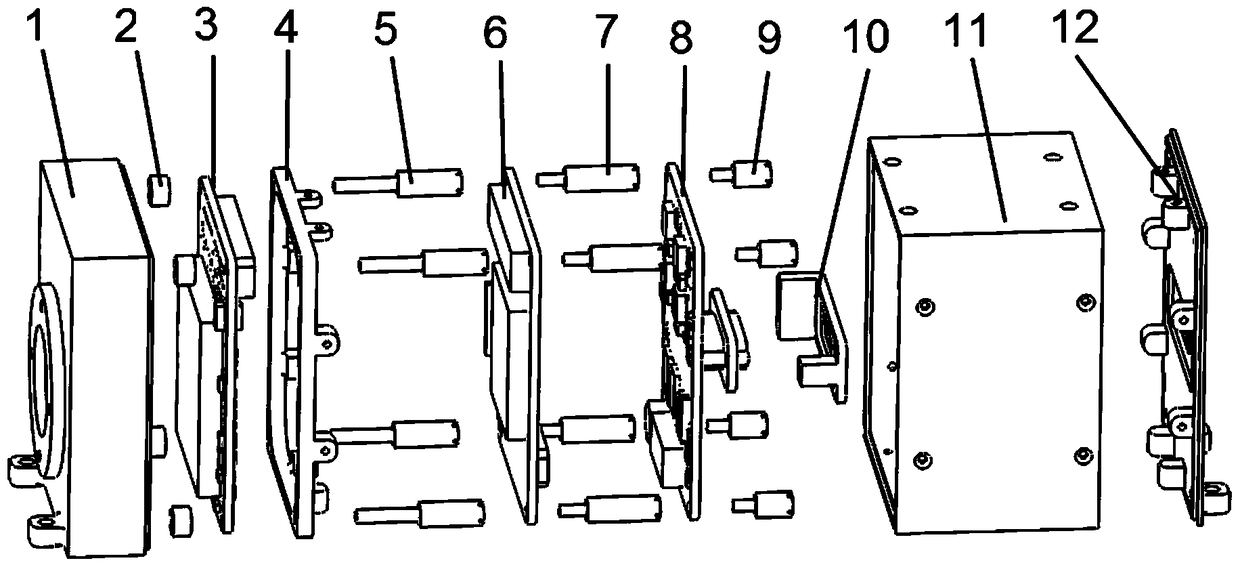

[0035] like Figure 4 As shown, there are three or more sets of connecting studs: the first set of connecting studs 5 , the second set of connecting studs 7 and the third set of connecting studs 9 . The connecting stud sets each include four connecting studs. The front of each connecting stud is externally threaded, and the rear end is internally threaded. The studs are connected end to end to form a series structure, which effectively reduces the overall weight of the camera and solves the problem of excessive weight of the traditional camera focal plane box.

[0036] Other circuit boards in the rear cavity are compressed by connecting stud two and connecting stud three, and the front end face of the studs of the back layer and the rear end face of the studs of the previous layer are fixed to other circuit boards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com