Soft start pre-assembled sub-station room

A pre-assembled and sub-station technology, applied in the field of solar energy, can solve problems such as frequent use of circuit breakers, large start-up stress, and large inrush current, and achieve the effects of reducing equipment malfunction, avoiding inrush current, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

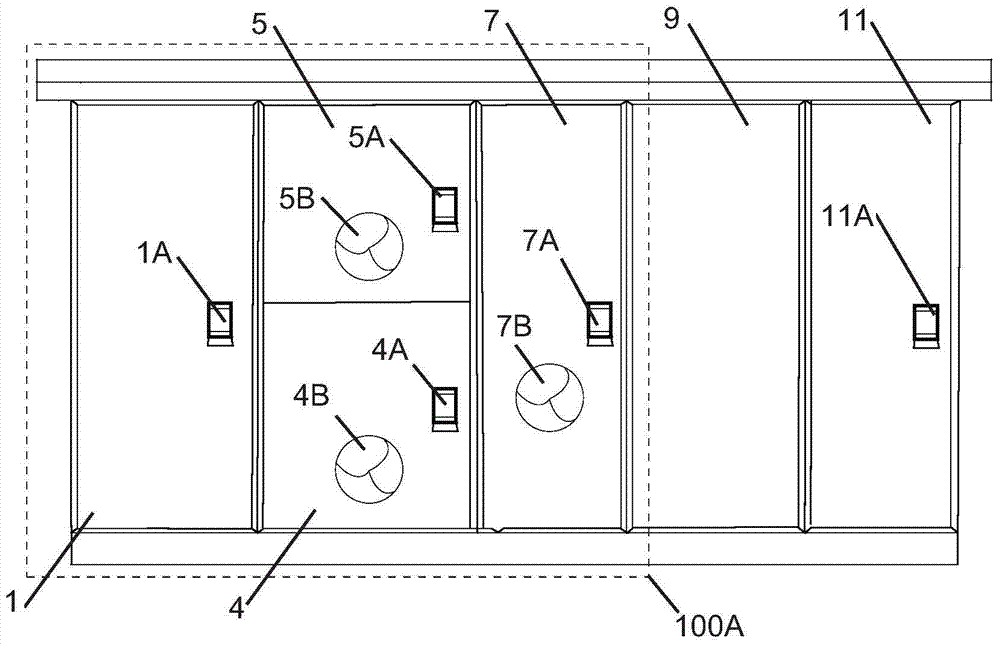

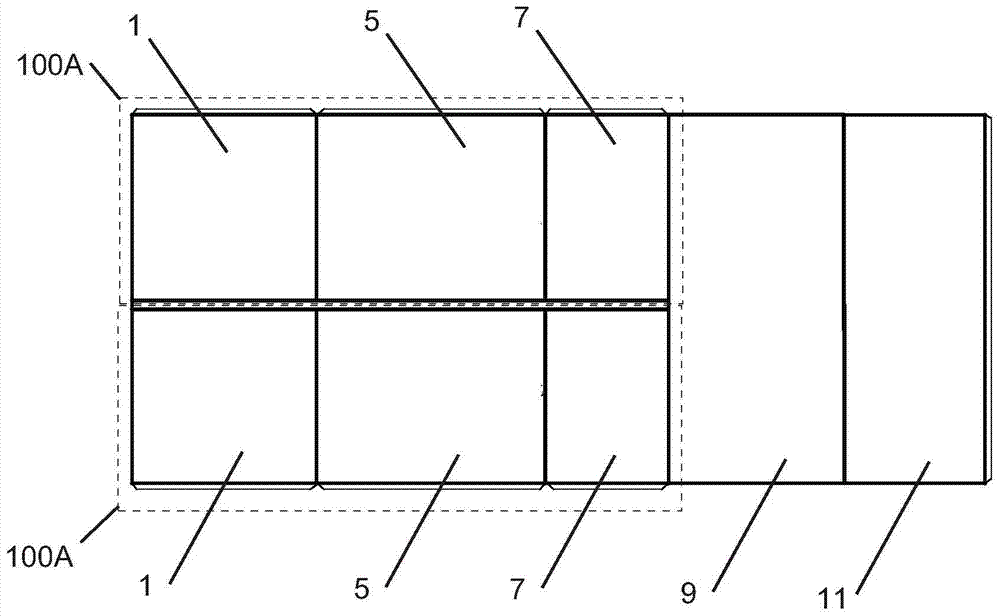

[0032] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

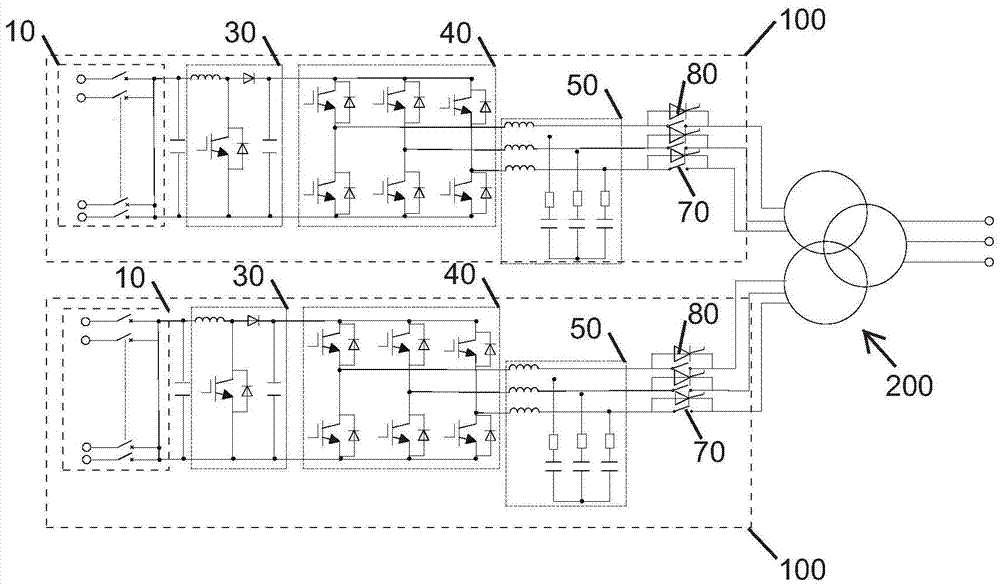

[0033] Glossary

[0034] Substation room: The electrical equipment that integrates photovoltaic inverters and box-type substations. This system converts the direct current generated by the photovoltaic array into alternating current, and completes a boost to supply the power grid.

[0035] Circuit breaker: The designed opening and closing device can close, break and carry the current in normal state; and it can also perform closing, breaking and conducting and breaking within a certain period of time under abnormal operating conditions.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com