A spp optical tweezers system

A technology of optical tweezers and a monitoring system, applied in the field of SPP optical tweezers systems, can solve the problems that single metal particles cannot be captured and manipulated, and the number of metal particles cannot be precisely controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

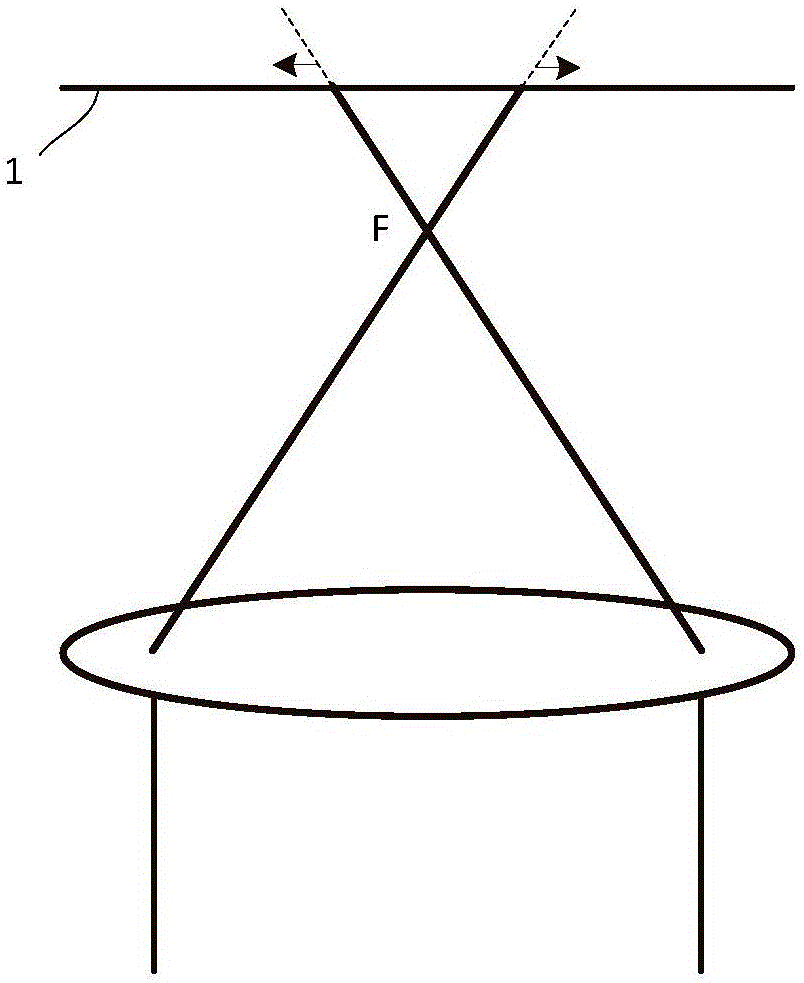

[0029] The SPP optical tweezers system of the present invention is used to manipulate metal particles on the interface between metal and medium, including an excitation light source unit, a monitoring system and an optical tweezers microscopic platform.

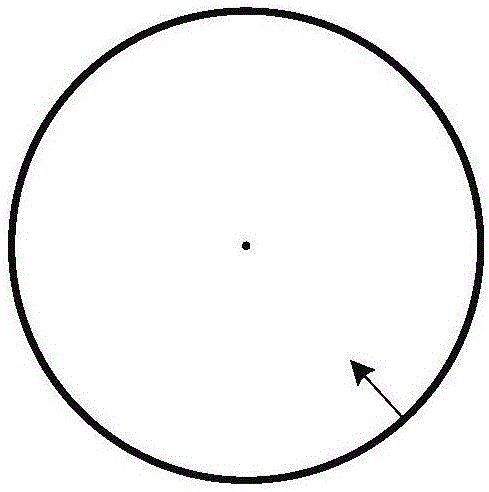

[0030] The optical tweezers micro platform includes an object stage on which the interface between the metal and the medium is formed. The excitation light source unit generates two incoherent laser beams, and makes the two incoherent laser beams generate a converging SPP field and a diverging SPP field at the metal-medium interface respectively, and the converging SPP field is included in the diverging SPP field. The converging SPP field forms a potential well to confine metal particles within it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com