Design method and apparatus for ensuring proper installation of CPU heat sink

A design method and heat sink technology, applied in the computer field, can solve problems such as poor heat dissipation, easy omission, automatic restart, etc., and achieve the effect of eliminating quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

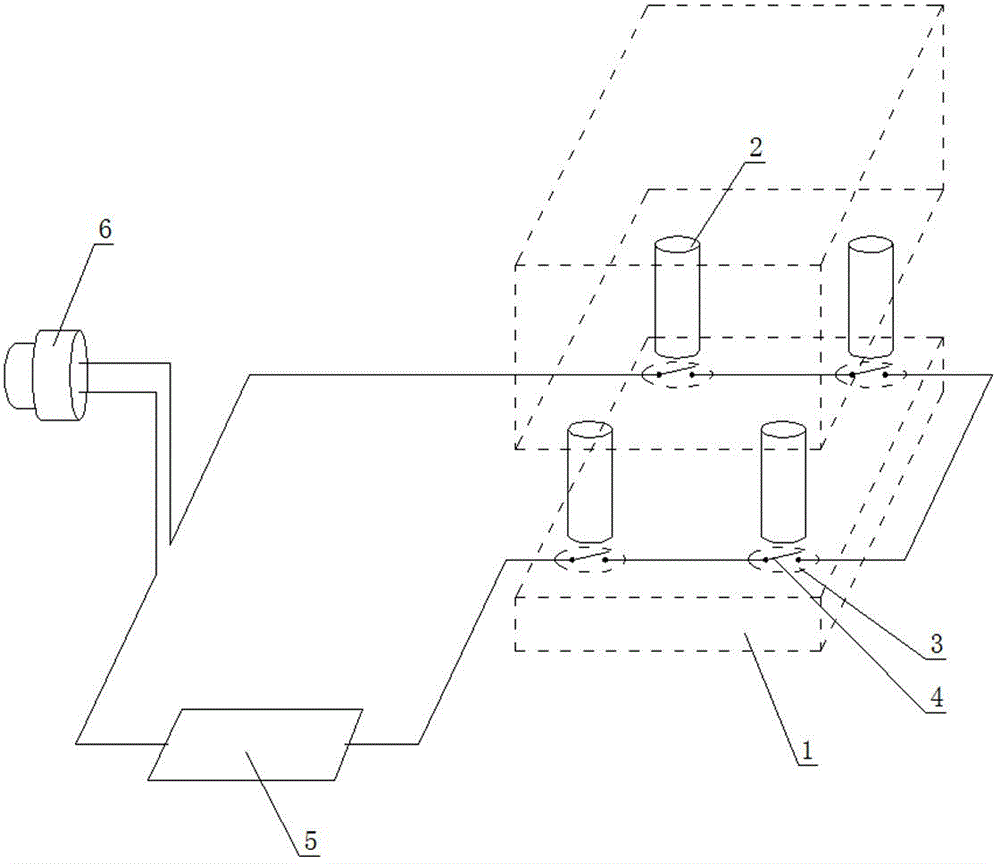

[0021] A design method and device for ensuring that the CPU radiator is installed in place of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] As shown in the accompanying drawings, a design method for ensuring that the CPU radiator is installed in place according to the present invention, its structure includes a motherboard power supply circuit and a CPU radiator,

[0023] At the base of the fixing screws at the four corners of the CPU cooler, add a pressure on-off circuit respectively,

[0024] Four pressure on-off circuits are serially connected in series,

[0025] The motherboard power circuit is connected in series with the power switch of the motherboard jumper, and the power switch of the motherboard jumper is connected in series with four pressure on-off circuits.

[0026] Four pressure on-off circuits are serially connected to the mainboard power supply circuit.

[0027] The pressure on-off circuit adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com