Sealing strip of cold storage door and refrigerator

A technology for seals and cold doors, applied in the field of cold storage door seals and refrigerators, can solve the problems of cracking of the inner tank, adhesion of the door seals, and increase of the heat transfer resistance of the door seals, so as to reduce energy consumption and improve the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

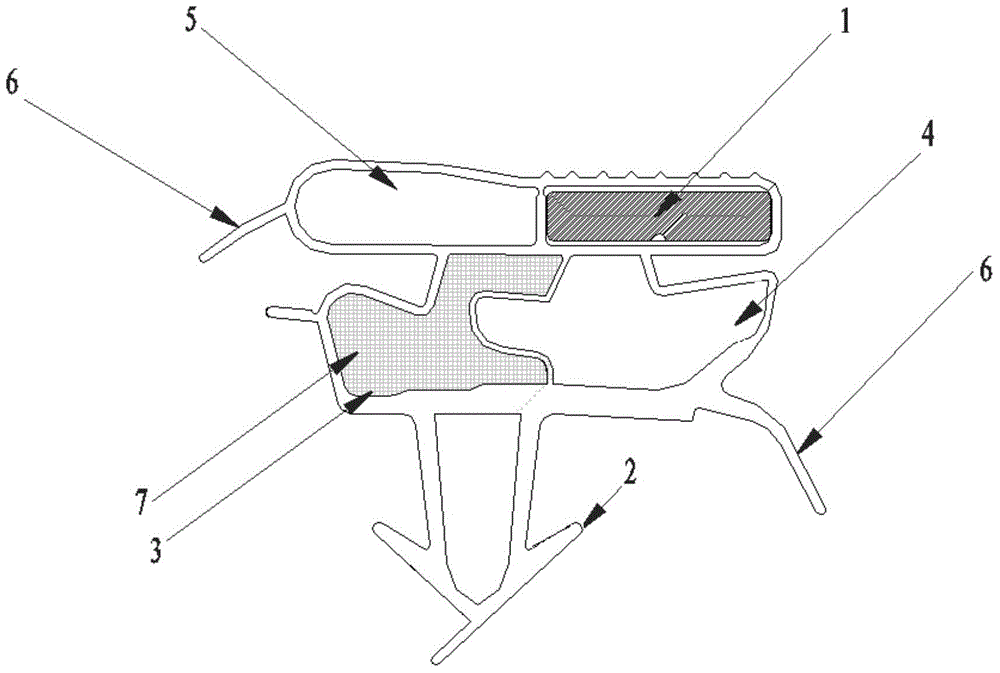

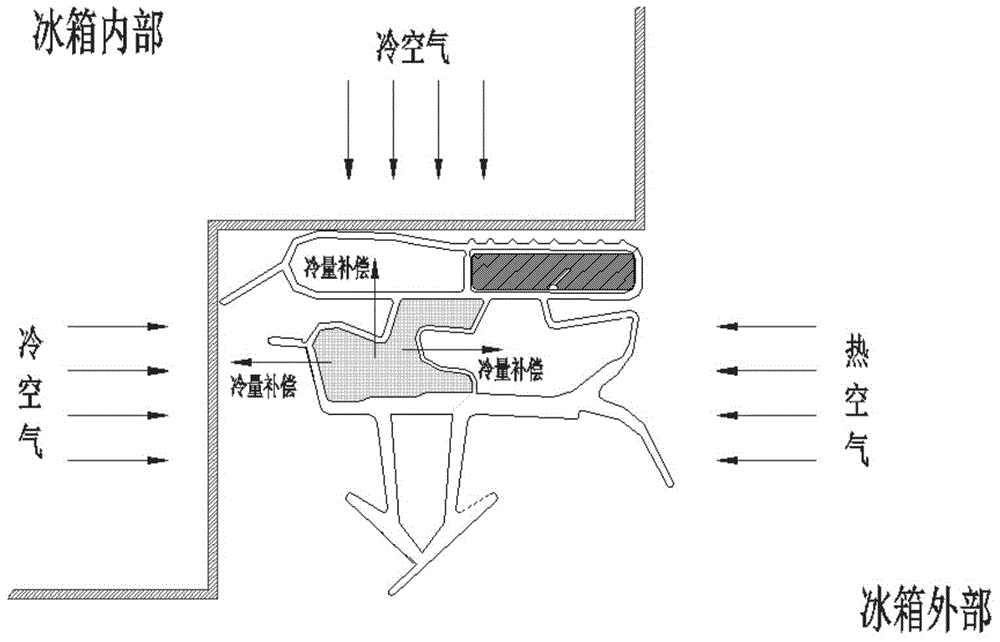

[0026] like figure 1 , figure 2 As shown, this embodiment provides a cold storage door seal, including an air bag, a magnetic strip chamber 1, a mounting foot 2, and a cold storage chamber 3 disposed adjacent to the air bag, and a cold storage medium 7 is arranged in the cold storage chamber 3 .

[0027] A magnetic strip is arranged in the above-mentioned magnetic strip cavity 1 for adsorbing the door body on the inner container of the refrigerator. The airbag is used to buffer the magnetic strip chamber 1 or the cold storage chamber 3 during the door closing process, and also has the function of isolating heat exchange inside and outside the refrigerator.

[0028] Preferably, the cold storage medium 7 is a phase change material, and the phase change temperature of the phase change material is 5°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com