An improved push chain type concrete sprayer

A concrete sprayer and push-chain type technology, which is applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve the problems of increased frictional resistance, short mixing time, shortened service life, etc., to reduce shear impact and wear , The effect of prolonging the blowing time and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A kind of improved push-chain type concrete sprayer of the present invention is described in detail below with reference to accompanying drawing of specification sheet.

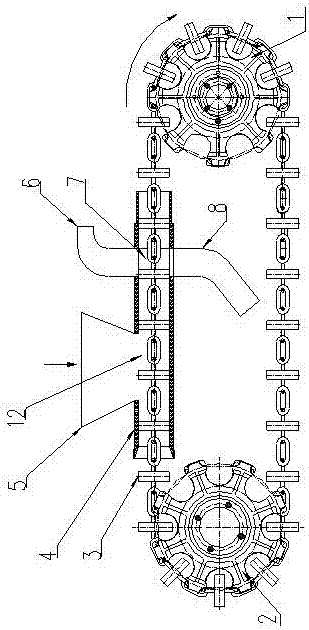

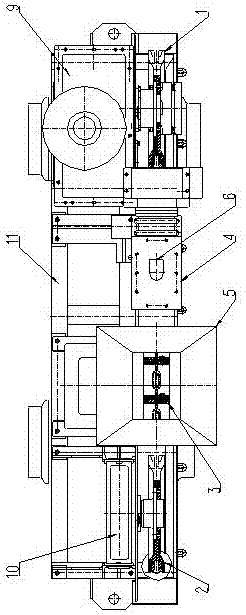

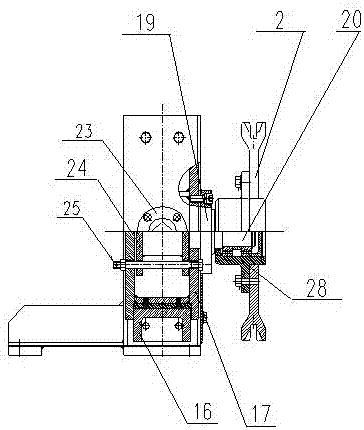

[0035] An improved push chain type concrete sprayer of the present invention has a structure consisting of a frame 11, a power output assembly, a driving sprocket 1, a passive sprocket assembly, a serial piston assembly, a chain tensioner assembly and Piston cylinder assembly, wherein, the driving sprocket 1 is connected to the power output shaft of the power output assembly 9, the passive sprocket assembly is connected to the chain tensioner assembly, and the power output assembly 9 and the chain tensioner assembly are respectively set At the left and right ends of the frame 11, the tandem piston assembly is looped around the driving sprocket 1 and the driven sprocket assembly, the piston barrel assembly 4 is arranged above the middle of the frame 11, and the tandem piston assembly Pass through the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com