Sintering technology for acidic pellet ore and alkaline material mixed ultra-thick material layer

A technology of mixed sintering and pelletizing, which is applied in the sintering field of iron and steel enterprises, can solve the problems of increased cost of blast furnace smelting, high enterprise investment, and reduced sintering speed, and achieve the effects of improving the quality of sintered ore, enhancing the oxidation atmosphere, and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

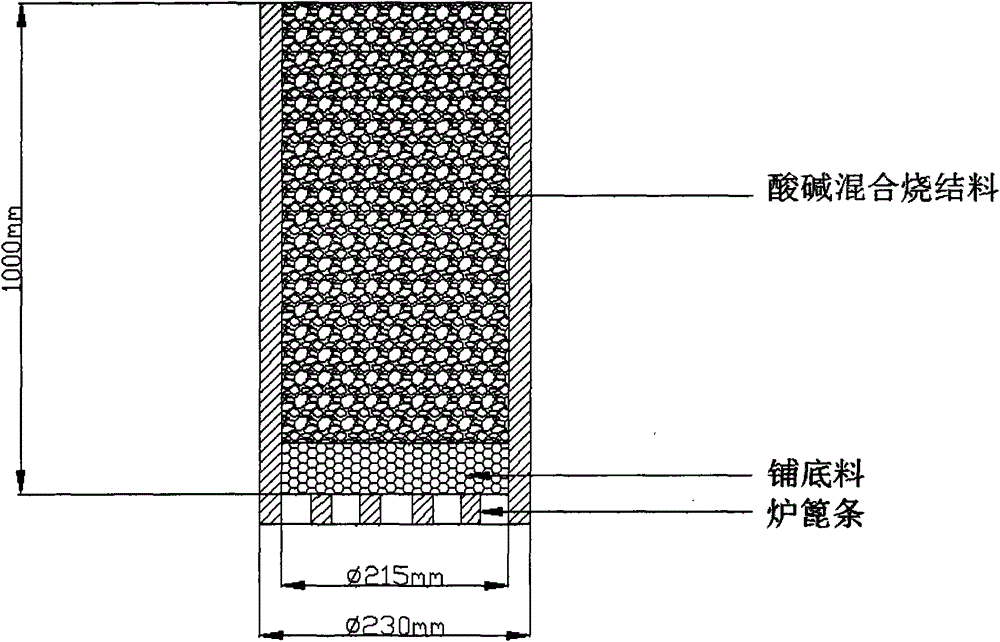

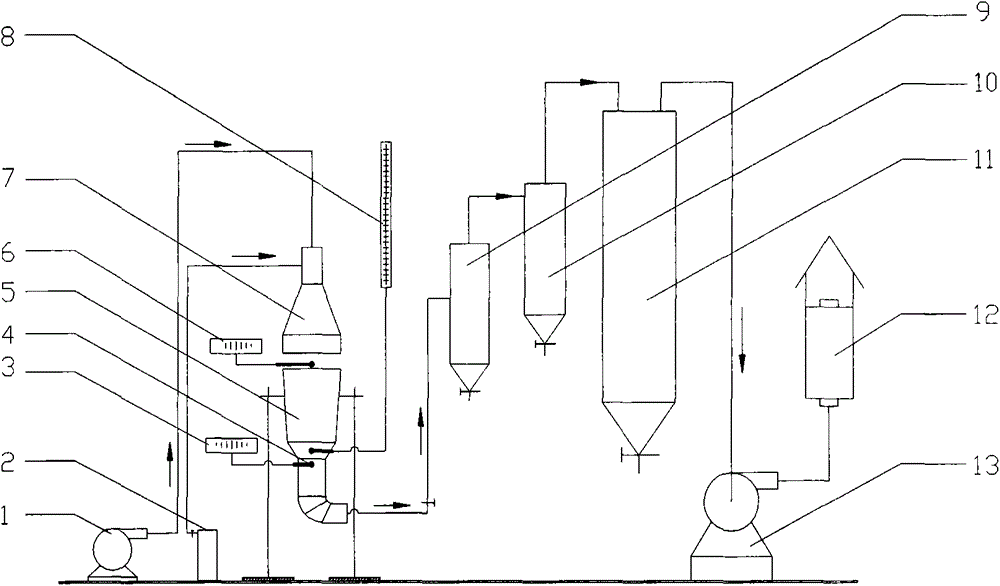

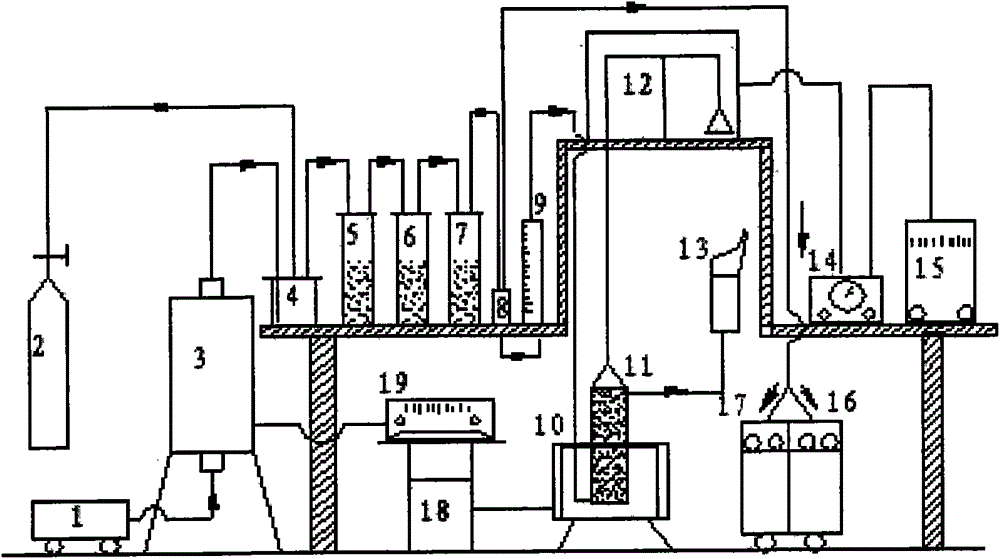

specific Embodiment 1

[0071] According to the requirements of pellet production, fully mix the vanadium-containing fine powder and bentonite according to the ratio of 95:5, and the content of the vanadium-containing fine powder with a particle size less than 0.074mm is greater than 70%, and the upper limit of the particle size does not exceed 0.2mm. After mixing Use a disc pelletizer to add water to make pellets, and divide the pellets into four grades of 5-8mm, 8-10mm, 10-12.5mm and >12.5mm; Flour, returned ore, lime and coke powder are mixed with water according to the ratio of 28:22:20:17:7:6, and the water content is about 6%, and then the mixed materials are added to the cylinder granulation Carry out secondary mixing in the machine, add water during the mixing process, the water content of the alkaline mixed material after adding water is about 7.5%; weigh 42kg of alkaline mixed material, 5.6kg of 5-8mm pellets, 8-10mm pellets 7kg of pellets, 12.6kg of 10-2.5mm pellets, and 2.8kg of >12.5mm p...

specific Embodiment 2

[0078] According to the requirements of pellet production, fully mix the vanadium-containing fine powder and bentonite according to the ratio of 95:5, and the content of the vanadium-containing fine powder with a particle size less than 0.074mm is greater than 70%, and the upper limit of the particle size does not exceed 0.2mm. After mixing Use a disc pelletizer to add water to make pellets, and divide the pellets into four grades of 5-8mm, 8-10mm, 10-12.5mm and >12.5mm; Flour, returned ore, lime and coke powder are mixed with water according to the ratio of 28:22:20:17:7:6, and the water content is about 6%, and then the mixed materials are added to the cylinder granulation Carry out secondary mixing in the machine, add water during the mixing process, the water content of the alkaline mixing material after adding water is about 7.5%; weigh 42kg of alkaline mixing material, 4.2kg of 5-8mm pellets, and 4.2kg of 8-10mm pellets 7kg of pellets, 11.2kg of 10-2.5mm pellets, and 5.6...

specific Embodiment 3

[0085] According to the requirements of pellet production, fully mix the vanadium-containing fine powder and bentonite according to the ratio of 95:5, and the content of the vanadium-containing fine powder with a particle size less than 0.074mm is greater than 70%, and the upper limit of the particle size does not exceed 0.2mm. After mixing Use a disc pelletizer to add water to make pellets, and divide the pellets into four grades of 5-8mm, 8-10mm, 10-12.5mm and >12.5mm; Flour, returned ore, lime and coke powder are mixed with water according to the ratio of 28:22:20:17:7:6, and the water content is about 6%, and then the mixed materials are added to the cylinder granulation Carry out secondary mixing in the machine, add water during the mixing process, the water content of the alkaline mixed material after adding water is about 7.5%; weigh 42kg of alkaline mixed material, 5.6kg of 5-8mm pellets, 8-10mm pellets 8.4kg of pellets, 11.2kg of 10-2.5mm pellets, 2.8kg of >12.5mm pel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com