Carboxyl functionalized micro-scale rod-like upconversion fluorescence material and preparation method thereof

A carboxyl-functionalized, fluorescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the application of micron-scale rod-shaped up-conversion fluorescent materials in the field of biological detection, the leakage of encoded microsphere fluorescent particles, and the fluorescence intensity of microspheres. Differences and other problems, to avoid spectral overlap, the preparation process is simple and easy, and the fluorescence is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

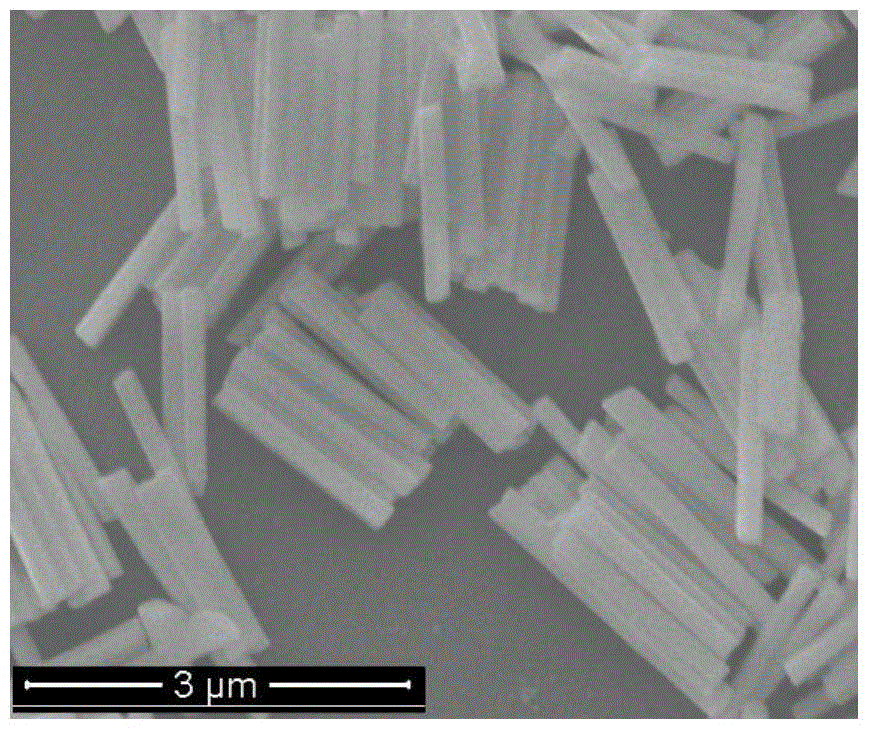

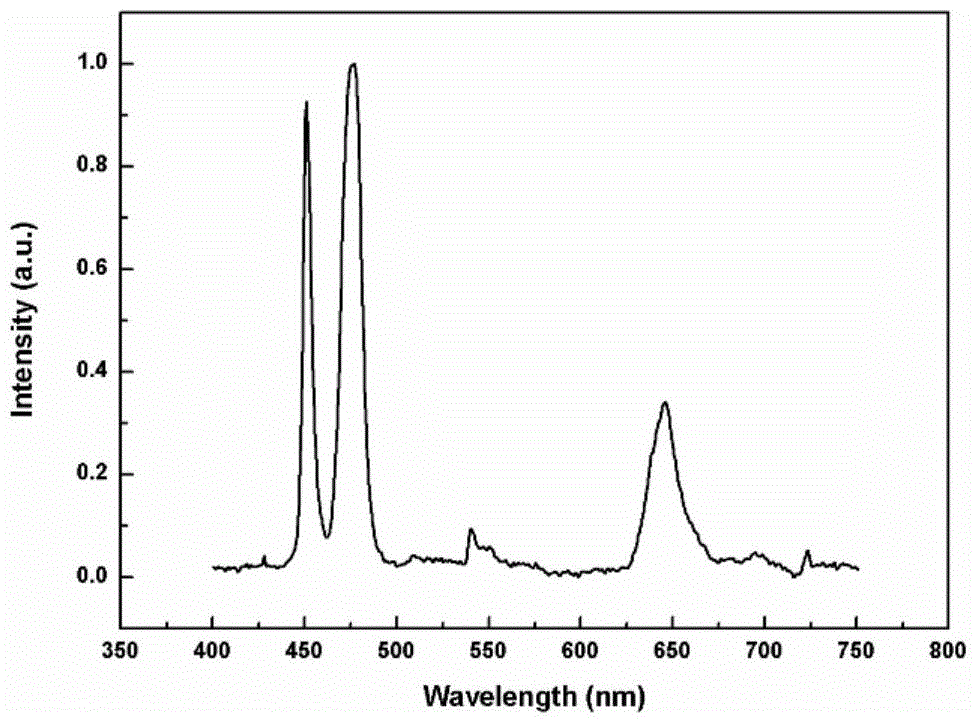

[0037] 1) Add an aqueous solution containing 4.5 mg of NaOH and a salt solution containing 12 mmol of rare earth elements in sequence to 25 mL of a mixed solution of ethanol and oleic acid (volume ratio = 1:1). Among them, the molar ratio of rare earth elements is Y 3+ : Yb 3+ : Tm 3+ =80:27:0.3.

[0038] 2) Add 1.85mg NH 4 For the aqueous solution of F, the mixed solution was stirred evenly and then transferred to a high-temperature reaction kettle, and kept at 180° C. for 12 hours;

[0039] 3) After the reaction is completed, the obtained white precipitate is washed with ethanol, dispersed in hydrochloric acid solution (2M) and ultrasonically washed for 3 minutes, and then cleaned again to obtain a pure micron-scale rod-shaped up-conversion fluorescent material with good dispersibility.

[0040]4) The obtained up-conversion material was added to a mixed solution of 25mL CTAB solution (5%), 0.33mL sodium hydroxide solution (2M) and 0.33mL TEOS, reacted at 80°C for 30min a...

Embodiment 2

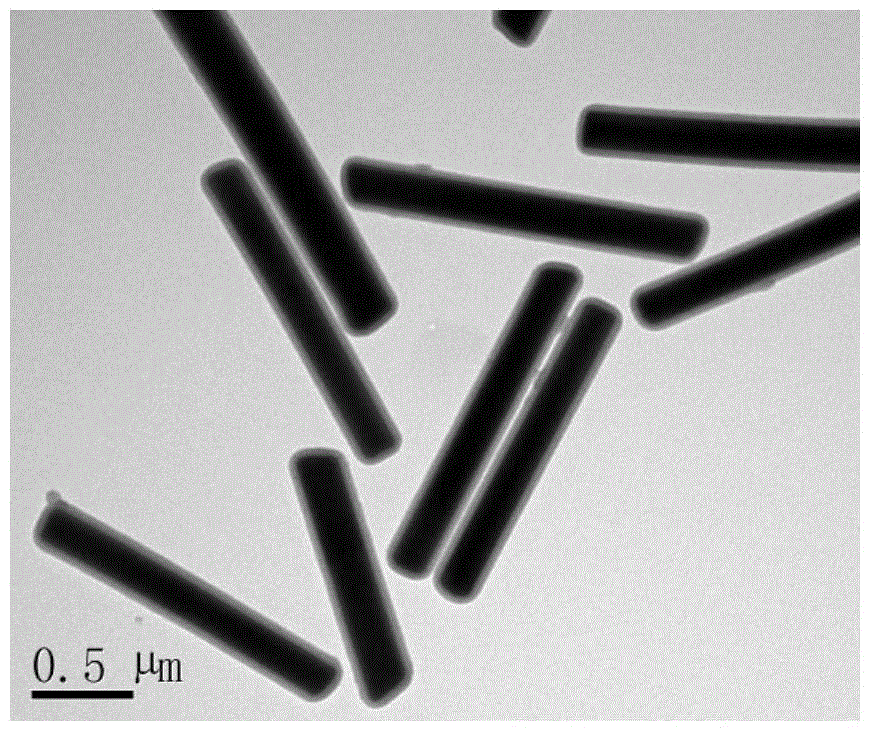

[0045] 1) Add an aqueous solution containing 4.5 mg of NaOH and a salt solution containing 12 mmol of rare earth elements in sequence to 25 mL of a mixed solution of ethanol and oleic acid (volume ratio = 1:1). Among them, the proportion of rare earth elements is Y 3+ : Yb 3+ :Er 3+ =80:20:1.

[0046] 2) Add 1.85mg NH 4 For the aqueous solution of F, stir the mixture for 30 minutes, transfer it to a high-temperature reaction kettle, and keep it at 180°C for 12 hours;

[0047] 3) After the reaction is completed, the obtained white precipitate is washed with ethanol, dispersed in hydrochloric acid solution (2M) and ultrasonically washed for 3 minutes, and then cleaned again to obtain a pure micron-scale rod-shaped up-conversion fluorescent material with good dispersibility.

[0048] 4) The obtained up-converting material was added to a mixed solution of 18.75mL CTAB solution (5%), 0.25mL sodium hydroxide solution (2M) and 0.25mL TEOS, reacted at 60°C for 30min and then centr...

Embodiment 3

[0052] 1) Into 25mL of a mixed solution of ethanol and oleic acid (volume ratio = 1:1), sequentially add an aqueous solution of 3.75mg of NaOH and a salt solution containing 8mmol of rare earth elements. Among them, the molar ratio of rare earth elements is Y3+: Yb 3+ :Er 3+ =80:80:0.08.

[0053] 2) Plus contains 1.48mg NH 4 For the aqueous solution of F, the mixed solution was stirred evenly and then transferred to a high-temperature reaction kettle, and kept at 200° C. for 8 hours;

[0054] 3) After the reaction is completed, the obtained white precipitate is washed with ethanol, dispersed in hydrochloric acid solution (2M) and ultrasonically washed for 3 minutes, and then cleaned again to obtain a pure micron-scale rod-shaped up-conversion fluorescent material with good dispersibility.

[0055] 4) The obtained up-conversion material was added to a mixed solution of 12mL CTAB solution (5%), 0.16mL sodium hydroxide solution (2M) and 0.16mL TEOS, reacted at 70°C for 30min a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com