Microcapsule temperature sensitive erasable neutral ink and preparation method thereof

A neutral ink, microcapsule technology, used in ink, printing, ballpoint pens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A second aspect of the present invention provides a method for preparing the microcapsule temperature-sensitive erasable neutral ink according to the present invention, which includes the following steps:

[0049] providing the various components of the invention;

[0050] The components are mixed and stirred until they are evenly mixed, filtered and defoamed to obtain the microcapsule temperature-sensitive erasable neutral ink.

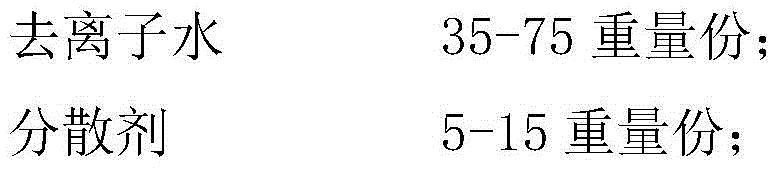

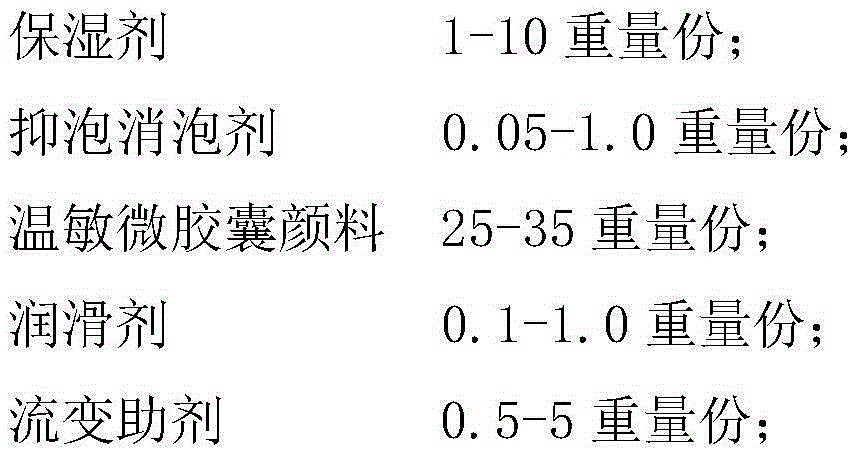

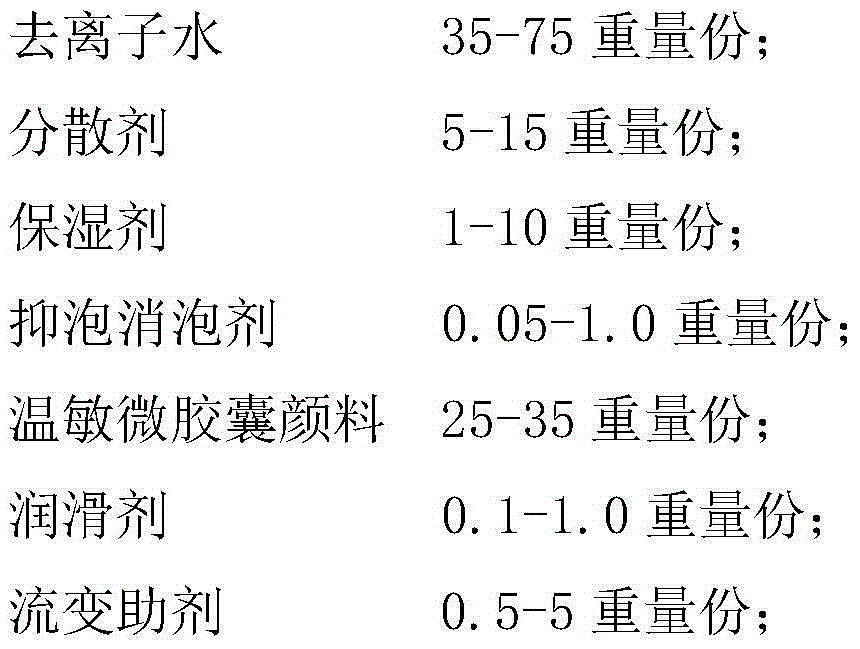

[0051]In a specific embodiment of the present invention, the 35-75 parts by weight of deionized water, the dispersant of 5-15 parts by weight, the moisturizing agent of 1-10 parts by weight, the foam inhibitor of 0.05-1.0 parts by weight Add the foaming agent into the dispersing container, add 25-35 parts by weight of the temperature-sensitive microcapsule pigment while stirring, and continue stirring until the pigment is evenly dispersed. Continue to add 0.1-1.0 parts by weight of lubricant and 0.5-5 parts by weight of rheological additives ...

Embodiment approach

[0054] A kind of microcapsule thermosensitive erasable neutral ink, its composition is

[0055]

[0056] The microcapsule pigments are irreversible thermal achromatic microcapsule pigments, reversible thermal achromatic microcapsule pigments,

[0057] Irreversible thermal achromatic pigments are mainly due to the thermal decomposition of materials to produce substances such as ammonia, carbon dioxide, and water, as well as sublimation, melting, compound reactions, and redox reactions that cause color changes. The color change temperature is generally higher. Preferably, a reversible thermally decolorized microcapsule pigment with a decolorizing temperature of 45-75° C. is used, which can be obtained through preparation or purchase. The interior of the reversible thermochromic microcapsule pigment is generally composed of 4 parts: (1) the organic matter that provides the thermochromic base, that is, the chromogenic agent; (2) the organic compound that causes thermal discolor...

Embodiment 1

[0068] First add 60.65g of deionized water, 9g of polyacrylic acid sodium salt (dispersant), 4g of 1.2-hexanediol (humectant), and 0.05g of polysiloxane emulsion (foam suppressing and defoaming agent) into the paddle-type vacuum degasser. Bubble dispersion tank, slowly add 25g of temperature-sensitive microcapsule pigment (decolorization temperature is 45°C) under stirring, stir for 30min, continue to add 0.3g of high molecular weight polydimethylsiloxane (lubricant) and 1g of Lithium-based montmorillonite clay (rheological additive), added in 3 times, stirred while adding until uniformly mixed, vacuum defoaming and then left to stand for one day to obtain microcapsule temperature-sensitive erasable neutral ink.

[0069] The writing performance and erasability of the obtained product were evaluated as "good", and the shear thinning index was 2.5. (The judging mode is referring to the performance embodiment, and the following embodiments are the same).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com