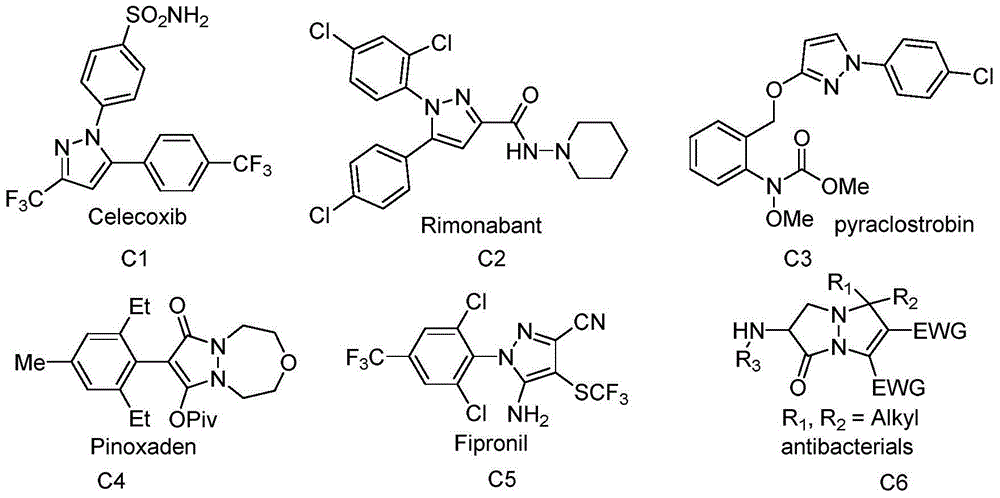

Tetralin pyrazolone triazine compound as well as preparation method and application thereof

A technology of triazine compound and tetrahydropyrazolone, which is applied in the field of organic compound preparation, can solve the problems of high cost and complicated preparation method, and achieve the effects of low cost, simple preparation method and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

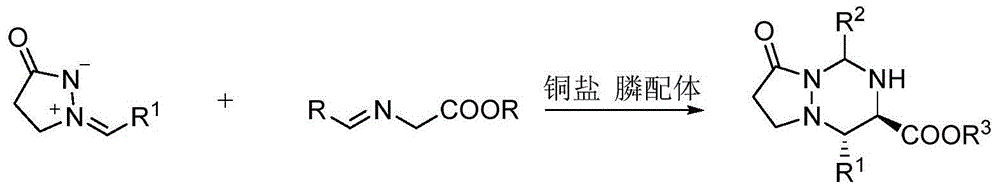

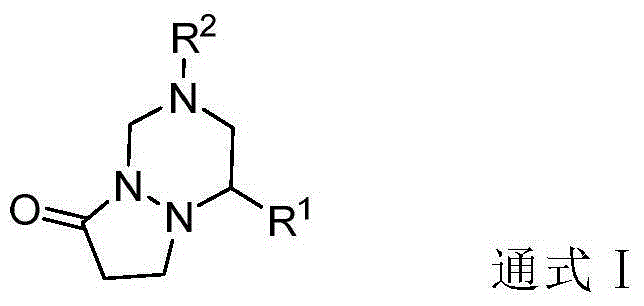

Method used

Image

Examples

Embodiment 1

[0025]

[0026] Add 2-(phenyl)pyrazolidine 3-ketoylide (0.125mmol), N-methoxy-N-trimethylsilylbenzylamine (Ⅲ) (0.125mmol) into a 15mL reaction tube, then add CH 2 Cl 2 (1 mL) and trifluoroacetic acid (0.0125 mmol). Then N-methoxy-N-trimethylsilylbenzylamine (Ⅲ) (0.375 mmol) was added in batches, and the reaction system was stirred at 10° C. for 72 h until the reaction was complete. The reaction solution was spin-dried and directly purified by silica gel column chromatography (eluent: petroleum ether / ethyl acetate=1 / 9) to obtain a white solid. 71% yield, a white solid. 1 H NMR (400MHz, Chloroform-d) δ7.36–7.27(m,10H),4.91(d,J=11.3Hz,1H),3.78–3.68(m,4H),3.36–3.25(m,1H), 2.96–2.89(m,1H),2.84–2.75(m,1H),2.69–2.60(m,2H),2.50–2.39(m,1H); 13 C NMR (101MHz, CDCl 3 )δ170.35, 138.03, 137.03, 129.04, 128.75, 128.52, 128.33, 127.74, 127.52, 66.99, 61.58, 58.68, 57.61, 47.96, 30.09; IR (film) ν max 3029,2924,2844,1695,1602,1494,1453,1410,1328,1280,1129,1065,1027,929,979,758,100,6...

Embodiment 2

[0028]

[0029] Add 2-(o-methylphenyl)pyrazolidine 3-ketoylide (0.125mmol) and N-methoxy-N-trimethylsilylbenzylamine (Ⅲ) (0.125mmol) into a 15mL reaction tube, Then add CH 2 Cl 2 (1 mL) and trifluoroacetic acid (0.0125 mmol). Then N-methoxy-N-trimethylsilylbenzylamine (Ⅲ) (0.375 mmol) was added in batches, and the reaction system was stirred at 10° C. for 72 h until the reaction was complete. The reaction solution was spin-dried and directly purified by silica gel column chromatography (eluent: petroleum ether / ethyl acetate=1 / 9) to obtain a white solid. 69% yield, a white solid. 1 H NMR (400MHz, Chloroform-d) δ7.52 (d, J = 7.5Hz, 0H), 7.58–7.48 (m, 2H), 7.40–7.08 (m, 9H), 4.93 (dd, J = 11.4, 1.9 Hz,1H),4.03(dd,J=10.3,2.7Hz,1H),3.83–3.69(m,3H),3.45–3.27(m,1H),2.89(dt,J=13.0,2.3Hz,1H) ,2.77–2.40(m,4H),2.28(s,3H); 13 C NMR (101MHz, CDCl 3 )δ170.52, 137.11, 136.08, 135.47, 130.54, 129.00, 128.51, 127.59, 127.54, 126.96, 126.57, 62.07, 61.71, 57.41, 57.36, 47.95, 30.14, 1...

Embodiment 3

[0031]

[0032] Add 2-(m-methylphenyl)pyrazolidine 3-ketoylide (0.125mmol) and N-methoxy-N-trimethylsilylbenzylamine (Ⅲ) (0.125mmol) into a 15mL reaction tube, Then add CH 2 Cl 2 (1 mL) and trifluoroacetic acid (0.0125 mmol). Then N-methoxy-N-trimethylsilylbenzylamine (Ⅲ) (0.375 mmol) was added in batches, and the reaction system was stirred at 10° C. for 72 h until the reaction was complete. The reaction solution was spin-dried and directly purified by silica gel column chromatography (eluent: petroleum ether / ethyl acetate=1 / 9) to obtain a white solid. 67% yield, a white solid. 1 H NMR (400MHz, Chloroform-d) δ7.52 (d, J = 7.6Hz, 1H), 7.39–7.32 (m, 3H), 7.30–7.11 (m, 5H), 4.93 (dd, J = 11.4, 1.9 Hz,1H),4.03(dd,J=10.4,2.7Hz,1H),3.86–3.72(m,3H),3.42–3.31(m,1H),2.93–2.85(m,1H),2.75–2.42( m,4H),2.28(s,3H); 13 C NMR (101MHz, CDCl 3 )δ170.52, 137.10, 136.07, 135.47, 130.53, 129.00, 128.51, 127.58, 127.53, 126.96, 126.56, 62.08, 61.71, 57.41, 57.35, 47.95, 30.14, 19.41; ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com