A kind of 3D printing cement-based material and preparation method thereof

A cement-based material and 3D printing technology, applied in the field of building materials, can solve problems affecting the connection between printing layers, poor extrusion performance and buildability, and hidden dangers in building safety, so as to achieve excellent buildability and improve work Good performance and construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

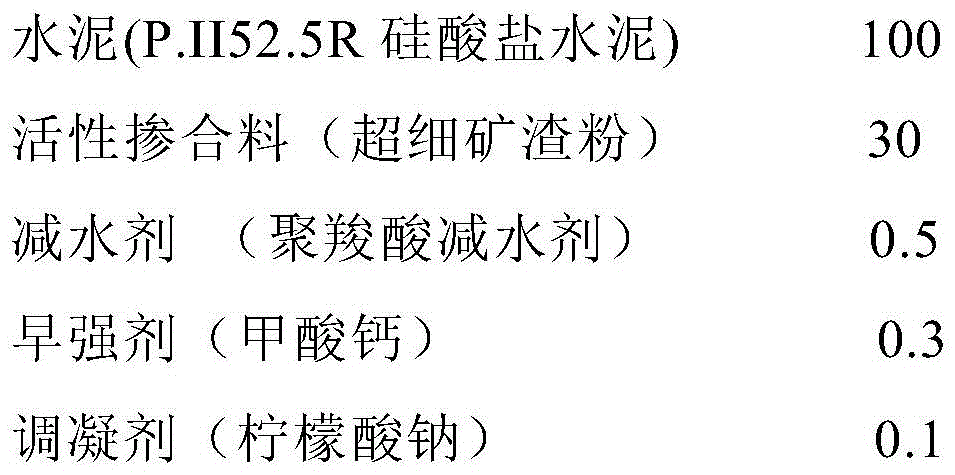

Embodiment 1

[0046]

[0047]

[0048] Character alignment preparation method: Weigh various raw materials according to the formula, and add cement (P.II52.5R Portland cement), active admixture (ultrafine slag powder), water reducer (polycarboxylate water agent), early strength agent (calcium formate), coagulation regulator (sodium citrate), expansion agent (UEA expansion agent), binder (redispersible latex powder), air-entraining agent (saponin), plastic The agent (carboxymethyl cellulose), starch ether, and fiber (polypropylene fiber) are fully stirred evenly to obtain a powdery gelatinous material, which is packaged to form a product.

[0049] During on-site construction, weigh fine aggregate (medium sand with a fineness modulus of 2.5) and coarse aggregate (crushed stone with a particle size smaller than 10mm) in proportion, put them into a special mixer and mix them evenly with powdered cementitious materials, and mix them in 1000kg Add 110kg of water to the material and stir eve...

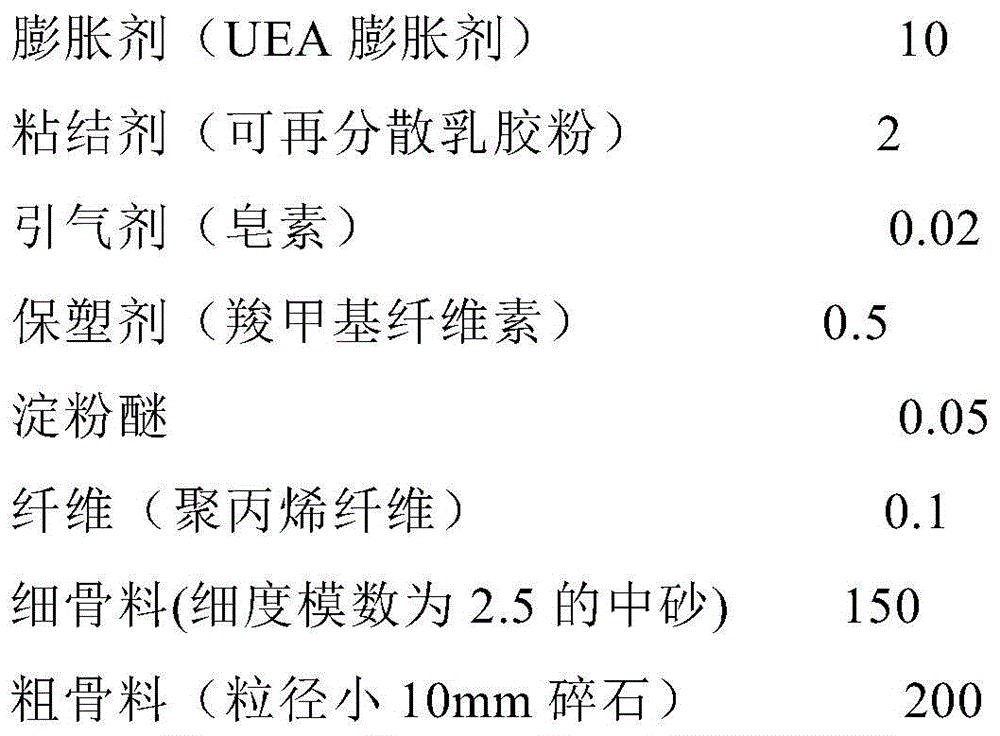

Embodiment 2

[0052]

[0053]

[0054] Preparation method: Weigh various raw materials according to the formula, and add cement (P.O 42.5 ordinary cement), active admixture (slag powder, fly ash), water reducer (naphthalene-based water reducer), and early strength to the mixer in sequence. agent (sodium metasilicate), coagulant (sodium citrate), expansion agent (ZY concrete expansion agent), binder (redispersible latex powder), air-entraining agent (sodium lauryl sulfate), Plasticizer (lignocellulose), water repellent (calcium stearate), starch ether, fiber (basalt fiber) are fully stirred evenly, and packaged to form a product.

[0055] During on-site construction, weigh fine aggregate (quartz sand of 10-60 mesh) and coarse aggregate (crushed stone with a particle size less than 10mm) in proportion, put them into a special mixer and mix them evenly with powdery cementitious materials, and add them to 1000kg of mixture Stir 120kg of water evenly to prepare the printed concrete mixture...

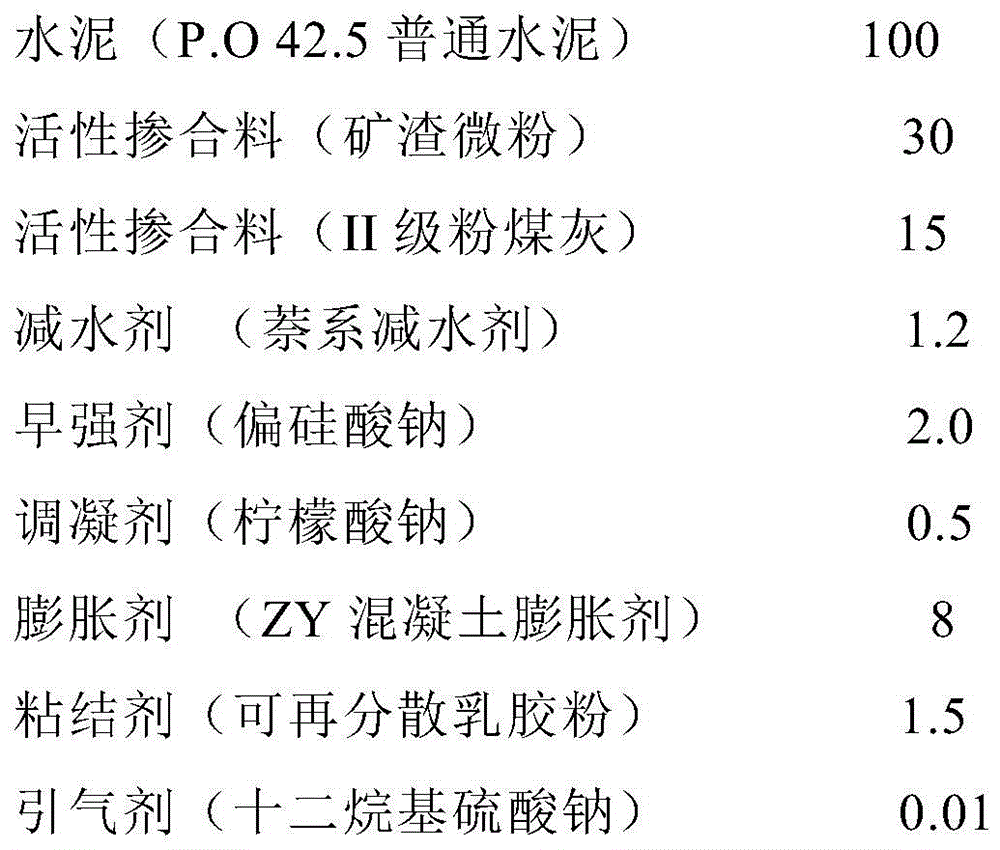

Embodiment 3

[0058]

[0059]

[0060] Preparation method: Weigh various raw materials according to the formula, and add cement (P.II52.5R Portland cement), active admixture (ultrafine slag powder, silicon powder), water reducer (polycarboxylic acid water reducer), early strength agent (sodium aluminate), expansion agent (UEA expansion agent, quicklime), binder (redispersible latex powder), air-entraining agent (saponin), plastic retainer (methyl hydroxy Propyl cellulose ether), water-repellent (calcium stearate), starch ether, and fiber (polypropylene fiber) are fully stirred evenly to obtain a powdery gelatinous material, which is packaged to form a product.

[0061] During on-site construction, weigh fine aggregate (medium sand with a fineness modulus of 2.5) and coarse aggregate (crushed stone with a particle size smaller than 10mm) in proportion, put them into a special mixer and mix them evenly with powdered cementitious materials, and mix them in 1000kg Add 105kg of water to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com