As-cast concrete and preparation method thereof

A technology of imitation fair-faced concrete and its manufacturing method, which is applied in the field of imitation fair-faced concrete and its preparation, can solve the problems that special walls cannot be constructed, the effect is difficult to guarantee, and the construction technology is complicated, so as to achieve favorable environmental protection, reduce consumption, and save oil The effect of natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

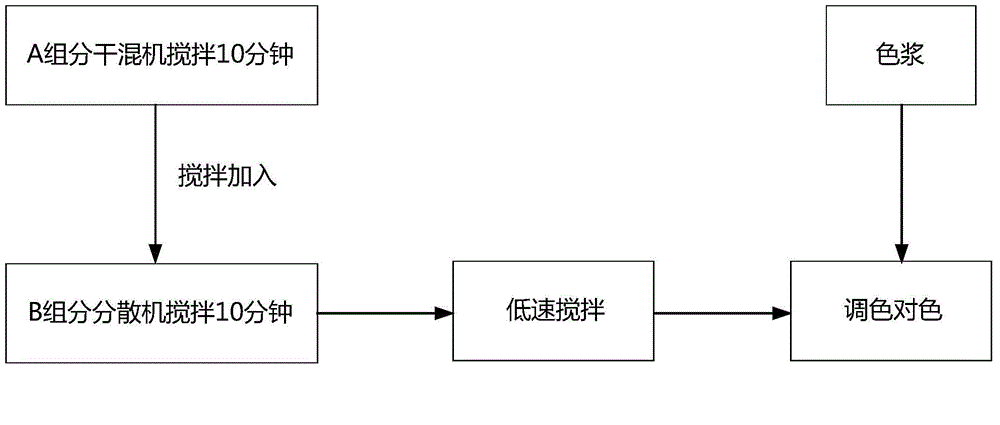

Method used

Image

Examples

Embodiment Construction

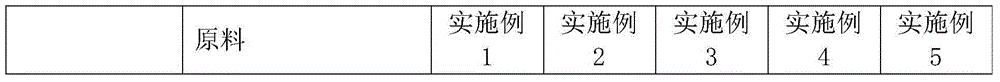

[0038] The technical solution of the present invention will be further described in detail through specific examples below, and the shown examples are only exemplary, and are only used to explain the present invention, and cannot be construed as limiting the present invention.

[0039] Referring to table 1, the formula composition comprising embodiment 1-embodiment 5:

[0040] Table 1

[0041]

[0042]

[0043] The mass percentage range of A component in Table 1 is: 60-72%; The mass percentage range of B component is 28-45%; The mass percentage range of color paste is: 0.1-0.4%; A component, B component, The sum of the mass percentages of color paste is 100%.

[0044] Among them: A component: inorganic bonding material such as: industrial grade 400 mesh calcium hydroxide, purity ≥ 90%; filler is 325 mesh -20 mesh graded white heavy calcium stone powder and river sand. Cellulose ether is HPMC-40US (average viscosity 40000cps, 2% solution / 20°C).

[0045] Component B: Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com