Purification tank

A purification tank and tank body technology, applied in the field of purification tanks, can solve the problems of long sewage residence time, high maintenance cost, incomplete sewage discharge, etc., and achieve good practical application value and promotion value, no operating cost, and easy operation and management. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

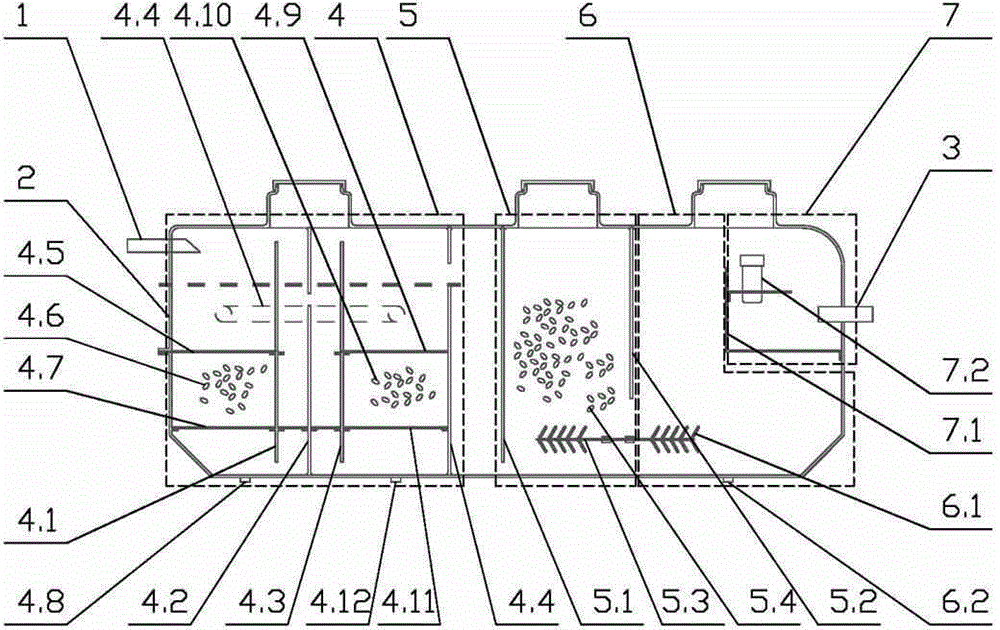

[0022] Such as figure 1 As shown, the septic tank, the septic tank, includes the water inlet pipe 1, the tank body 2, the water outlet pipe 3 connected to the summarized sewage flowing out of the toilet, kitchen, and washing room, and several slag-clearing holes and slag-cleaning holes located at the upper end of the tank body 2 hole cover;

[0023] The tank body 2 is sequentially divided into an anaerobic chamber 4, an explosion chamber 5, a sedimentation chamber 6 and a disinfection chamber 7 from left to right, and a circulation pump 4.4 is provided in the anaerobic chamber 4.

[0024] Specifically, the anaerobic chamber 4 is separated by the first partition 4.1, the second partition 4.2 and the third partition 4.3 into the first anaerobic chamber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com