Method for preparing highly-oriented MFI-type molecular sieve membrane by secondary growth process

A secondary growth and orientation technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of corrosiveness of synthesis liquid, harsh conditions, and relatively high carrier requirements, and achieve simple operation, continuous film layer, and good orientation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) The preparation of the secondary growth synthesis solution, according to the molar ratio of the composition of the synthesis solution: Tetraethyl orthosilicate (TEOS): tetrapropylammonium hydroxide (TPAOH): water = 1:0.2:200, TEOS, TPAOH Mix with water, stir at room temperature for 3 hours, add the calculated amount of ammonium sulfate aqueous solution to the clarified mixed solution, and continue stirring for 1 hour to obtain the final synthetic solution; the molar composition of the final synthetic solution is: TEOS:TPAOH:H 2 O: ammonium sulfate=1:0.2:200:0.075

[0030] 2) Put the carrier coated with the b-axis orientation seed layer into a high-pressure synthesis kettle, pour the above synthesis liquid, and seal; crystallize at 150°C for 3 hours;

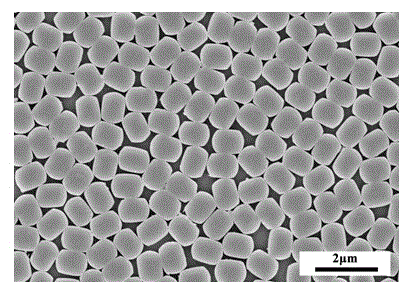

[0031] 3) Cool the synthesis kettle, take out the carrier, wash and dry, and obtain an oriented MFI molecular sieve membrane on the carrier, such as figure 2 .

Embodiment 2

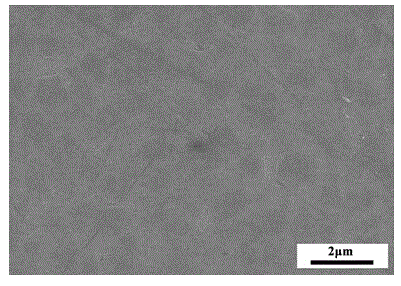

[0033] With embodiment 1, the molar composition of final synthetic liquid is: TEOS:TPAOH:H 2 O: ammonium sulfate=1:0.2:200:0.1; crystallize at 150°C for 4 hours; obtain MFI molecular sieve membrane on the carrier, such as image 3 , and its X-ray diffraction pattern is as Figure 4 , the resulting molecular sieve membrane is of height b Axially oriented MFI type molecular sieve membrane.

Embodiment 3

[0035] 1) The preparation of the secondary growth synthetic solution, according to the molar ratio of the synthetic solution: TEOS:TPAOH:H 2O=1:0.1:250, mix TEOS, TPAOH and water, stir at room temperature for 5 hours, add the calculated amount of ammonium bicarbonate aqueous solution into the clear mixed solution, and continue stirring for 1 hour to obtain the final synthetic solution; finally synthesize The molar composition of the liquid is: TEOS:TPAOH:H 2 O: ammonium bicarbonate=1:0.1:250:0.1;

[0036] 2) Put the carrier coated with the b-axis orientation seed layer into a high-pressure synthesis kettle, pour the above synthesis liquid, and seal; crystallize at 180°C for 3 hours;

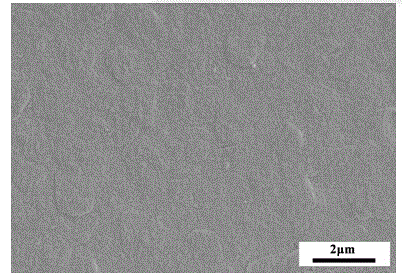

[0037] 3) Cool the synthesis kettle, take out the carrier, wash and dry, and obtain an oriented MFI molecular sieve membrane on the carrier, such as Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com