Grinding medium adopting shape of dual-spherical hexagonal prism

A grinding medium and hexagonal technology, applied in the fields of metallurgy, casting and beneficiation, can solve problems such as over-crushing, and achieve the effect of reducing over-crushing, improving quality and realizing resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

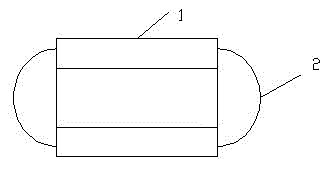

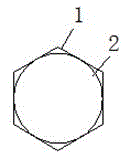

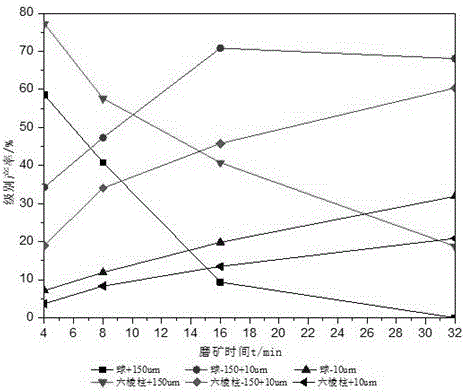

[0013] Such as figure 1 , figure 2 As shown, the present invention is achieved in this way, a double-spherical hexagonal prism grinding medium, the body of the grinding medium is a hexagonal prism 1, and the two ends of the hexagonal prism 1 are connected with hemispherical surfaces 2 to form a double-spherical hexagonal prism The grinding medium increases the surface contact on the basis of the traditional point contact type and line contact type during the grinding process to reduce the degree of over-grinding of the grinding product. The grinding medium material is cast iron, the main elements and weight content (%) are C: 2.1~3.6; Si: 1.2; Mn: 2.0; Cr: 1.5~3.0; Mo: 1.0; Ni: 1.0; Cu: 1.2 , the material can increase the wear resistance of this double spherical hexagonal prism medium. In the treatment process of the double-spherical hexagonal prism grinding medium, the grinding medium material is heated to 960-1000° C., kept for 24 hours, and then air-cooled after being re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com