Particle red-mud adsorbent preparing method used for phosphate adsorption

An adsorbent and red mud technology, applied in the field of environmental treatment, can solve the problems of unsuitability for large-scale popularization and application, low strength and porosity of ceramic adsorbent, poor adsorption performance, etc., achieve good phosphate adsorption capacity, and solve the problem of phosphoric acid The effect of salt recovery and easy access to materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

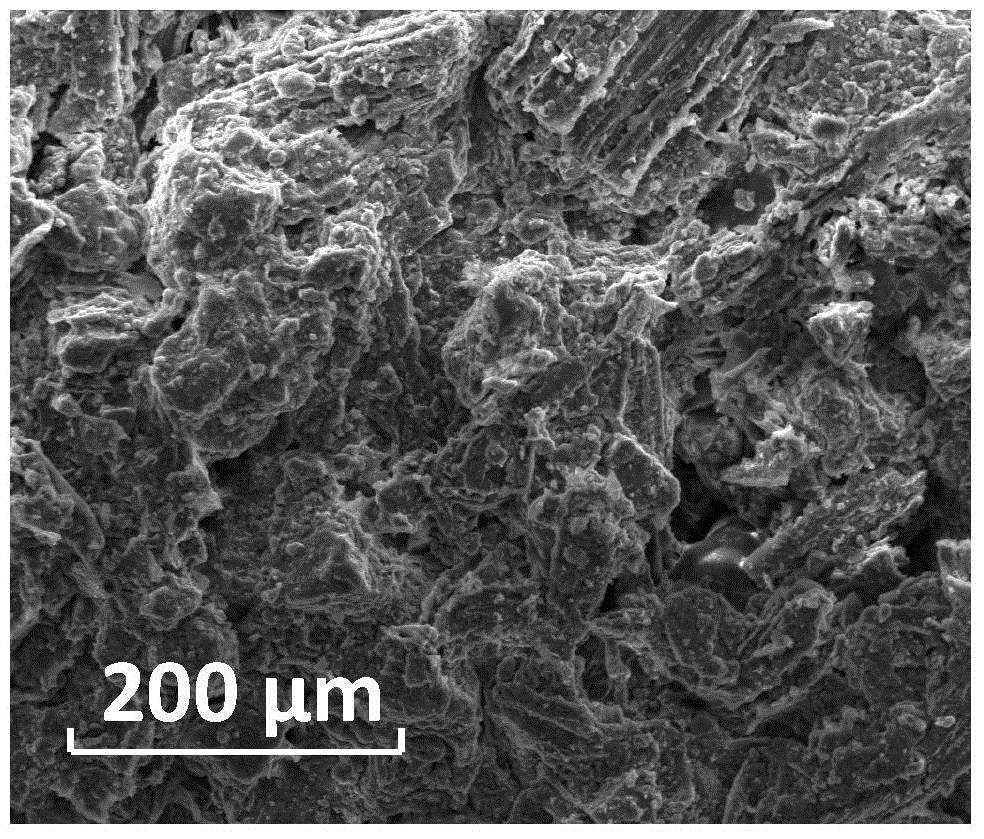

Image

Examples

Embodiment 1

[0031] (1) Take a certain amount of raw red mud, mix it with the calcium and magnesium ion solution at a weight ratio of 1:5, and stir continuously until the pH reaches 8.4;

[0032] (2) Separating the above-mentioned red mud mixture with calcium and magnesium ions into solid and liquid, and washing the solid sample with deionized water for several times until the pH of the filtrate is neutral, and then drying the solid sample at 100° C. for 12 hours;

[0033] (3) Grinding and sieving the dried sample after natural cooling to obtain neutralized red mud with a particle size of 100 μm;

[0034] (4) Add the neutralized red mud to the hydrochloric acid solution of 10.0mol / L at the dosage of 0.5g / L, and react at 40°C for 5h;

[0035] (5) Separating the above red mud mixed with hydrochloric acid solution into solid and liquid, and washing the solid sample with deionized water for several times until the pH of the filtrate is neutral, then drying the solid sample at 100°C for 12 hour...

Embodiment 2

[0044] Prepare a phosphate solution with an initial concentration of 500 mg / L and an initial pH of 7.0, add the red mud particles prepared in Example 1, and stir at 100 rpm for 48 hours at a temperature of 40°C. The results obtained are as follows: the specific surface area and total pore volume of the red mud particles are 113.54m 2 / g and 0.0287cm 3 / g. The phosphate adsorption capacity of unit particle red mud-based adsorbent reached 84.56mg / g.

Embodiment 3

[0046] (1) Take a certain amount of raw red mud, mix it with the calcium and magnesium ion solution at a weight ratio of 1:5, and stir continuously until the pH reaches 8.4;

[0047] (2) Separating the above-mentioned red mud mixture with calcium and magnesium ions into solid and liquid, and washing the solid sample with deionized water for several times until the pH of the filtrate is neutral, and then drying the solid sample at 100° C. for 12 hours;

[0048] (3) Grinding and sieving the dried sample after natural cooling to obtain neutralized red mud with a particle size of 100 μm;

[0049] (4) Add the neutralized red mud to the hydrochloric acid solution of 10.0mol / L at the dosage of 0.5g / L, and react at 40°C for 5h;

[0050] (5) Separating the above-mentioned red mud mixture with hydrochloric acid solution into solid and liquid, and washing the solid sample with deionized water for several times until the pH of the filtrate is neutral, and then drying the solid sample at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com