Method for detecting transient faults of fire pump in quick starting process

A quick start and water pump technology, applied in pump testing, machine/engine, liquid variable capacity machinery, etc., can solve problems such as burnout, unit equipment and pipeline damage, local power grid overload or current shock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Characteristic of the present invention can be shown by following technical steps:

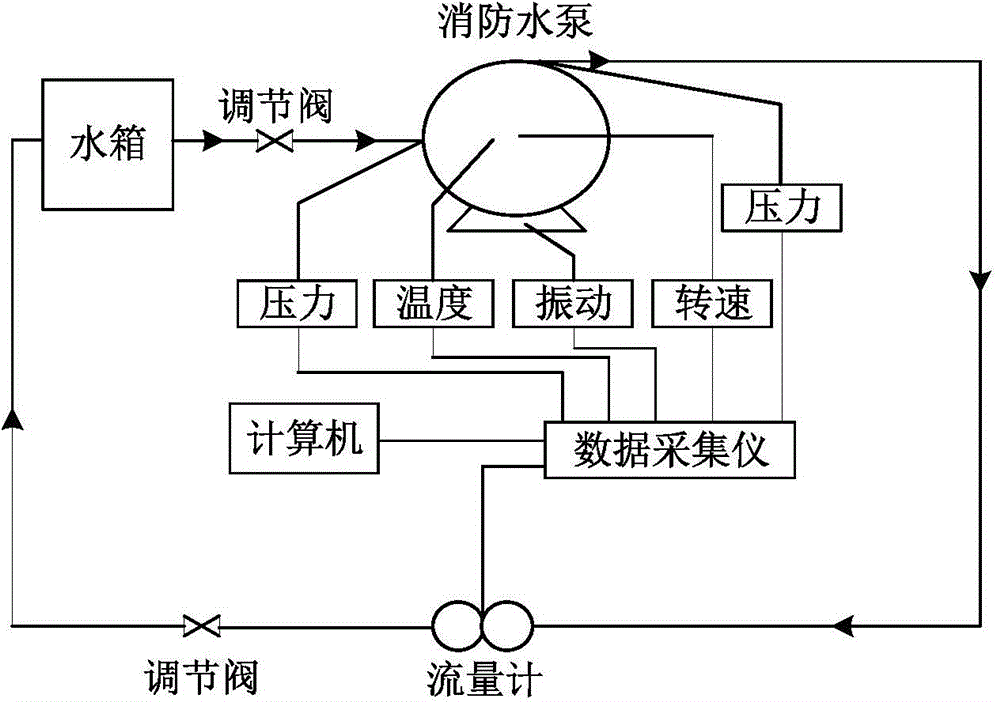

[0034] Step 1: Establish a closed circulation pipeline including the fire pump, install a vibration sensor on the base of the fire pump, install a speed torque sensor on the shaft, install a pressure sensor at the inlet and outlet of the fire pump, and install a flow sensor at the outlet of the fire pump to establish a fire pump Controlled testbed.

[0035] Step 2: Set the sampling frequency of the data acquisition card, collect data synchronously from each sensor, obtain the water pressure, pipeline flow, pump vibration, temperature and other signals of the fire pump during the start-up process, and upload them to the host computer in real time through Ethernet , to perform time-domain analysis and processing to obtain signal amplitude and other information.

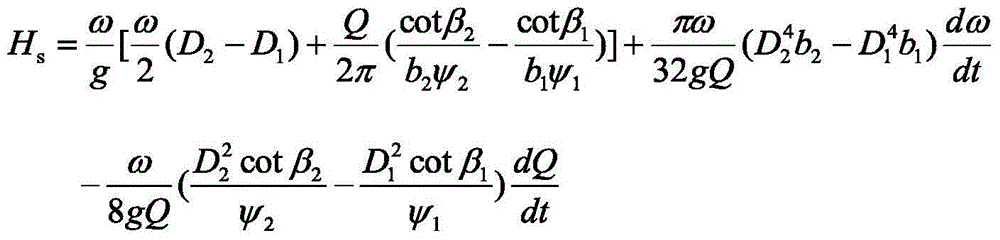

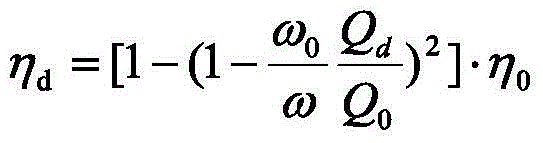

[0036] Step 3: Calculate the instantaneous head of the fire pump according to the inherent mechanical characteristics and flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com