Sub-wavelength three-dimensional spiral circular polarizing filter and manufacturing method thereof

A spiral circle and optical filter technology, applied in the field of optical filters, can solve the problems of low discrimination, difficult production, complex structure and process, etc., and achieve the effect of strong circular dichroism, simple structure and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

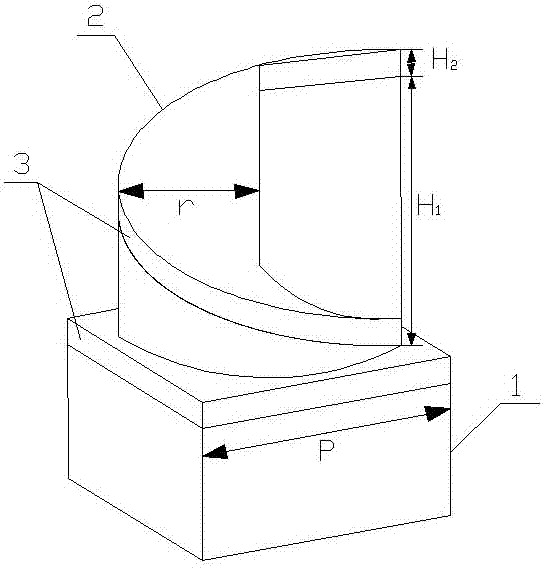

[0021] Embodiment one: see figure 1 As shown, a sub-wavelength three-dimensional helical circular polarizing filter includes a silicon dioxide substrate 1, a three-dimensional helical nanocolumn 2 disposed on the silicon dioxide substrate, and a surface covering the silicon dioxide substrate and the three-dimensional helical nanocolumn. Metal thin film layer 3, the radius of the three-dimensional helical nanocolumn is r=0.95um, and the height is H 1 =2um, the period of each three-dimensional helical nanocolumn is P=1.9um, and the thickness of the metal film layer is H 2 =0.1um.

[0022] In this embodiment, the material of the metal thin film layer may be gold, silver, aluminum, copper or titanium nitride.

[0023] A method for manufacturing a sub-wavelength three-dimensional spiral circular polarizing filter, comprising the steps of:

[0024] (1) Spin-coat photoresist on a silicon dioxide substrate;

[0025] (2) Using a laser direct writing system to directly write a three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com