LED panel lamp with thermal conductive plastic frame free of substrate packaging

A technology of LED panel lights and thermally conductive plastics is applied in the parts of lighting devices, cooling/heating devices of lighting devices, optical elements for changing the spectral characteristics of emitted light, etc. Low thermal conductivity, hindering the dissipation of heat, etc., to achieve the effect of rich color, fewer parts and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

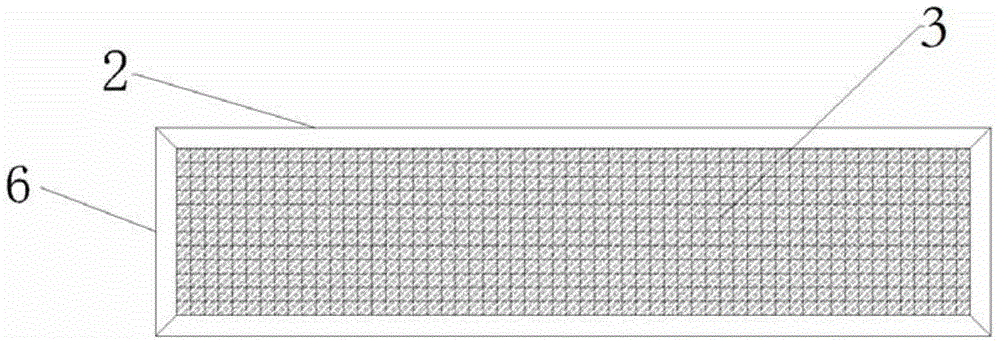

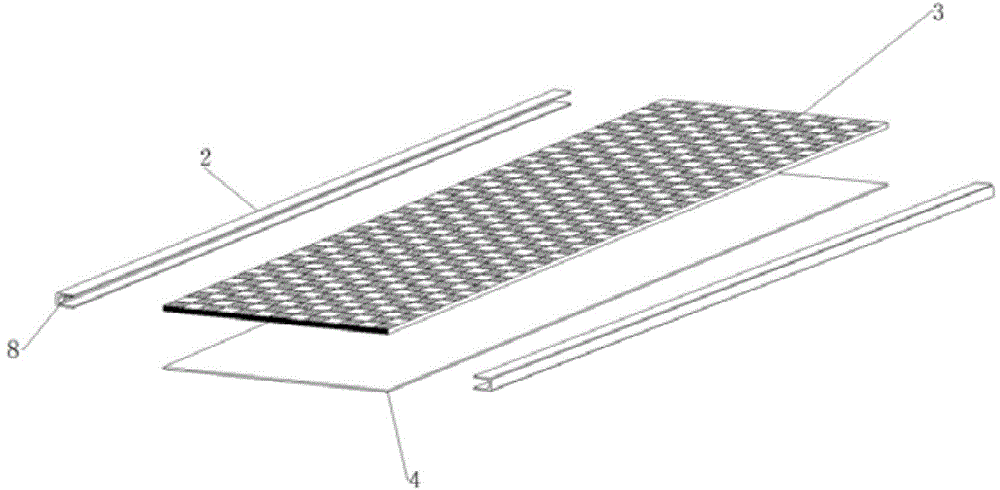

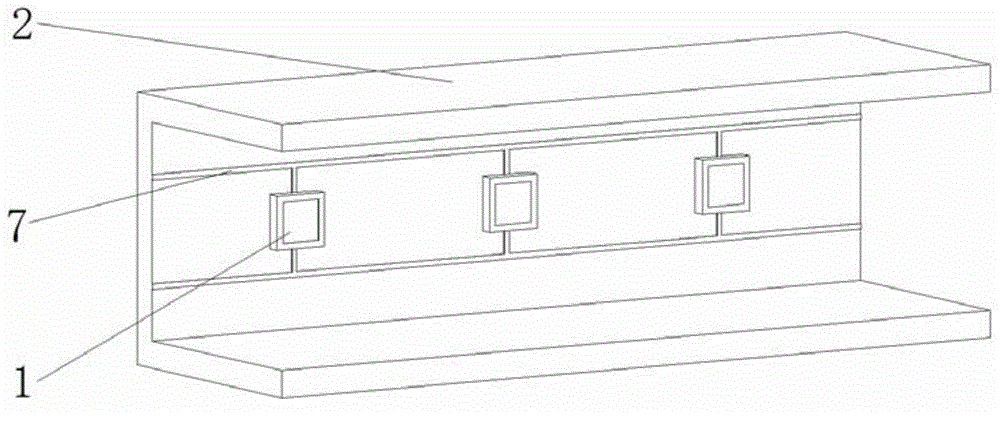

[0028] Such as Figure 1 to 5 As shown, this embodiment discloses an LED flat light packaged with a thermally conductive plastic frame without a substrate, which includes an LED chip 8, a back plate 4, a light guide plate 3, and a groove-shaped thermally conductive plastic frame 6, through which the thermally conductive plastic frame passes Set around the back plate 4 and the light guide plate 3, fixed and load-bearing the light guide plate 3 and the back plate 4 through the groove; the LED chip is packaged on the surface of the heat-conducting plastic frame groove through the COB packaging technology, as the edge light source of the LED flat light . In this embodiment, the light guide plate is an integrated integrated light guide plate, and the diffusion microstructure is integrated into the light guide plate, thereby eliminating the need for a diffusion film. In addition, the light guide plate is not attached to the side and back of the LED chip with a reflective film.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com