Collection wire wiring structure for detecting voltage of energy storage type sodium-sulfur battery module

A sodium-sulfur battery and wiring structure technology, applied in the direction of measuring current/voltage, measuring devices, measuring electrical variables, etc., can solve the problem of large number of sodium-sulfur batteries, reduce data volume, reduce heat dissipation channels, and save system resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

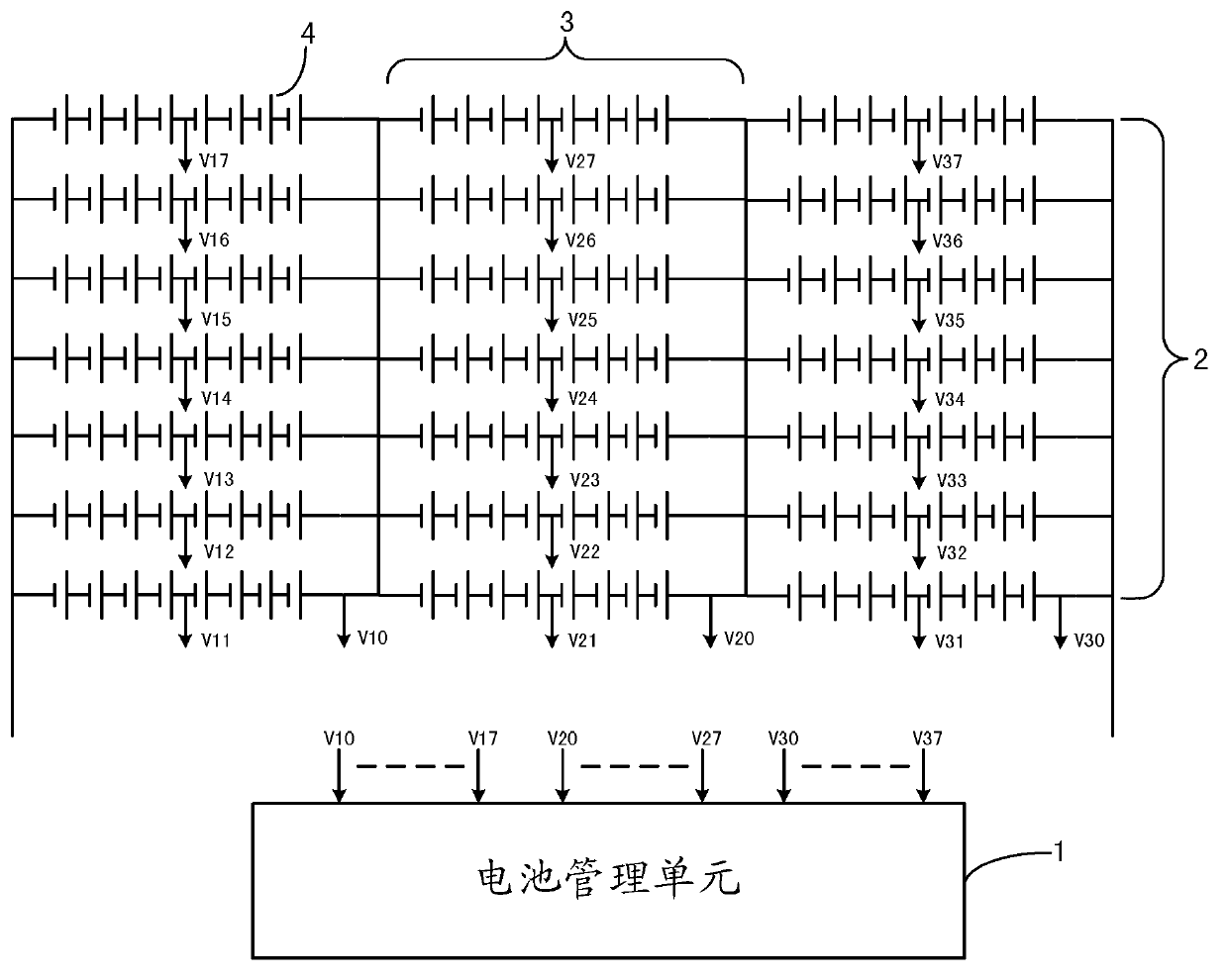

[0010] see figure 1 , the present invention is used for the acquisition line wiring structure of the energy storage sodium-sulfur battery module voltage detection, including the energy storage sodium-sulfur battery module and the battery management unit 1 arranged in the incubator, and the energy storage sodium-sulfur battery module is composed of several serially connected The parallel battery pack 2 is composed of a number of sodium-sulfur battery series units 3 connected in parallel with each other, and the sodium-sulfur battery series unit 3 is composed of several single sodium-sulfur batteries 4 in series. From each sodium-sulfur battery series unit The voltage acquisition lines drawn from the middle points V11-V17, V21-V28 and V31-V37 of 3, and the right side V10, V20 and V30 of the parallel battery pack 2 are connected to the battery management unit 1 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com