Method for judging position of failure cell in energy storage type sodium-sulfur cell module

A sodium-sulfur battery and battery technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of large number of sodium-sulfur batteries, achieve the effects of reducing data volume, reducing heat dissipation channels, and flexible wiring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

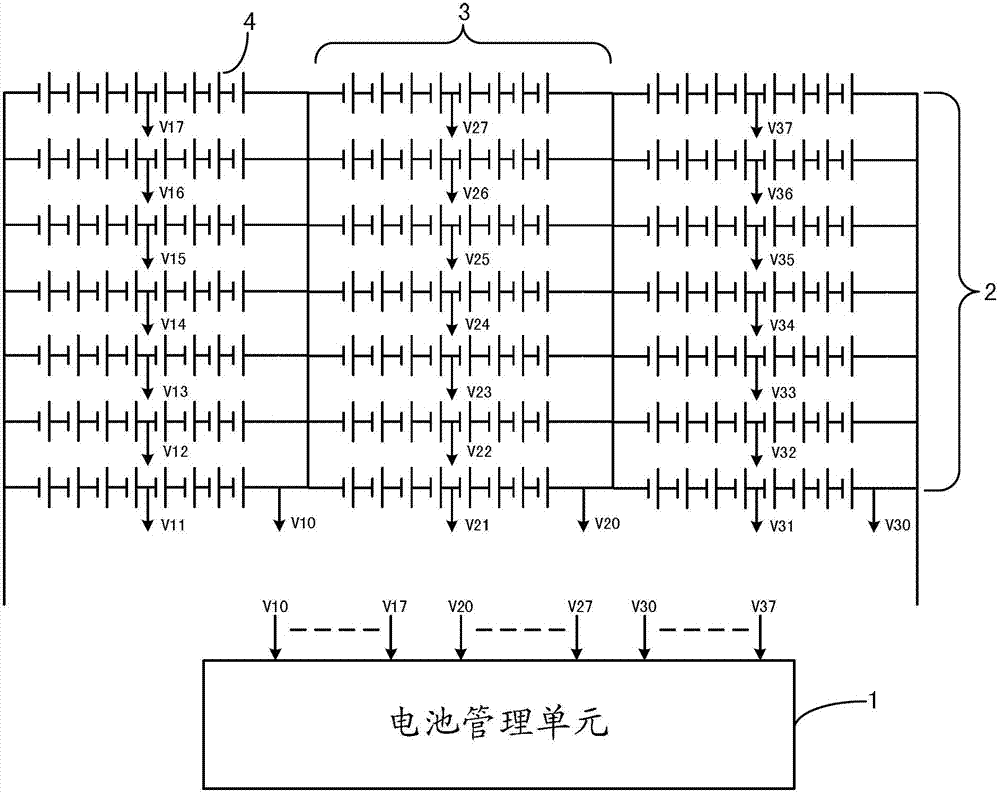

[0012] see figure 1 , the energy storage sodium-sulfur battery module is composed of several sub-circuits 2 connected in series in sequence. The sub-circuit 2 is composed of several sodium-sulfur battery series units 3 connected in parallel with each other. Composed in series, a voltage acquisition line is drawn from any point of each sodium-sulfur battery series unit 3 except its two ends and the right side of the sub-circuit 2 to connect to the battery management unit 1 .

[0013] The method of the present invention for judging the location of a faulty battery in an energy storage sodium-sulfur battery module comprises the following steps:

[0014] S1: The battery management unit 1 collects the voltages V11-V17, V21-V28, and V31-V37 of the middle points of each sodium-sulfur battery series unit through the voltage collection line as comparison voltages, and simultan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com