Method for adopting pH gradient elution method to synchronously separate triterpenoid saponins and licorice flavonoid

A triterpenoid saponins and synchronous separation technology, applied in the field of chemical compounds, can solve the problems of high energy consumption and ethanol consumption of solvent recovery, and achieve the effects of full utilization, reduction of consumption, and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

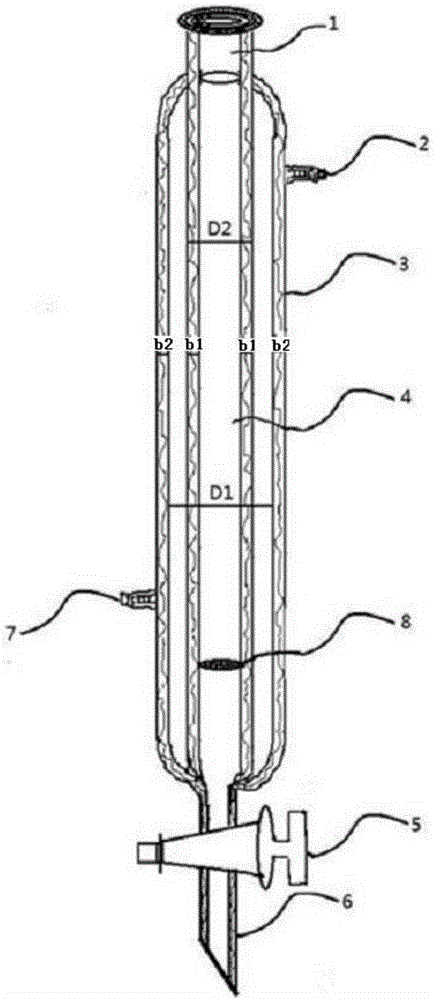

Image

Examples

Embodiment 1

[0036] The pH gradient elution method of the present invention is applied to the process technology and equipment for synchronously separating triterpene saponins and licorice flavonoids in licorice paste, including the following steps:

[0037] 1. Preparation of loading solution

[0038] The licorice fluid extract to be recycled after extracting polysaccharides was stirred and dissolved with purified water at room temperature (fluid extract:purified water volume ratio 1:4), centrifuged for 20min (speed 4000r / min), and the supernatant was prepared into a suitable concentration as the loading solution.

[0039] 2. Pretreatment of macroporous resin

[0040]Soak the pharmaceutical-grade resin HPD100, which was optimized by the static adsorption and elution experiment, in ethanol for 24 hours, then wash the resin with a large amount of purified water until it has no alcohol smell, and soak it in water for later use.

[0041] 3. Sample loading and adsorption: Accurately weigh the...

Embodiment 2

[0046] The pH gradient elution method of the present invention is applied to the process technology and equipment for synchronously separating triterpene saponins and licorice flavonoids in licorice paste, including the following steps:

[0047] 1. Preparation of loading solution

[0048] The licorice fluid extract to be recycled after extracting polysaccharides was stirred and dissolved with purified water at room temperature (fluid extract:purified water volume ratio 1:4), centrifuged for 20min (speed 4000r / min), and the supernatant was prepared into a suitable concentration as the loading solution.

[0049] 2. Pretreatment of macroporous resin

[0050] Soak the pharmaceutical-grade resin HPD400, which was optimized by the static adsorption and elution experiment, in ethanol for 24 hours, then wash the resin with a large amount of purified water until it has no alcohol smell, and soak it in water for later use.

[0051] 3. Sample loading and adsorption: Accurately weigh th...

Embodiment 3

[0056] The pH gradient elution method of the present invention is applied to the process technology and equipment for synchronously separating triterpene saponins and licorice flavonoids in licorice paste, including the following steps:

[0057] 1. Preparation of loading solution

[0058] The licorice fluid extract to be recycled after extracting polysaccharides was stirred and dissolved with purified water at room temperature (fluid extract:purified water volume ratio 1:4), centrifuged for 20min (speed 4000r / min), and the supernatant was prepared into a suitable concentration as the loading solution.

[0059] 2. Pretreatment of macroporous resin

[0060] Soak the pharmaceutical-grade resin HPD450, which was optimized by the static adsorption and elution experiment, in ethanol for 24 hours, wash the resin with a large amount of purified water until it has no alcohol smell, and soak it in water for later use.

[0061] 3. Sample loading and adsorption: Accurately weigh the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com