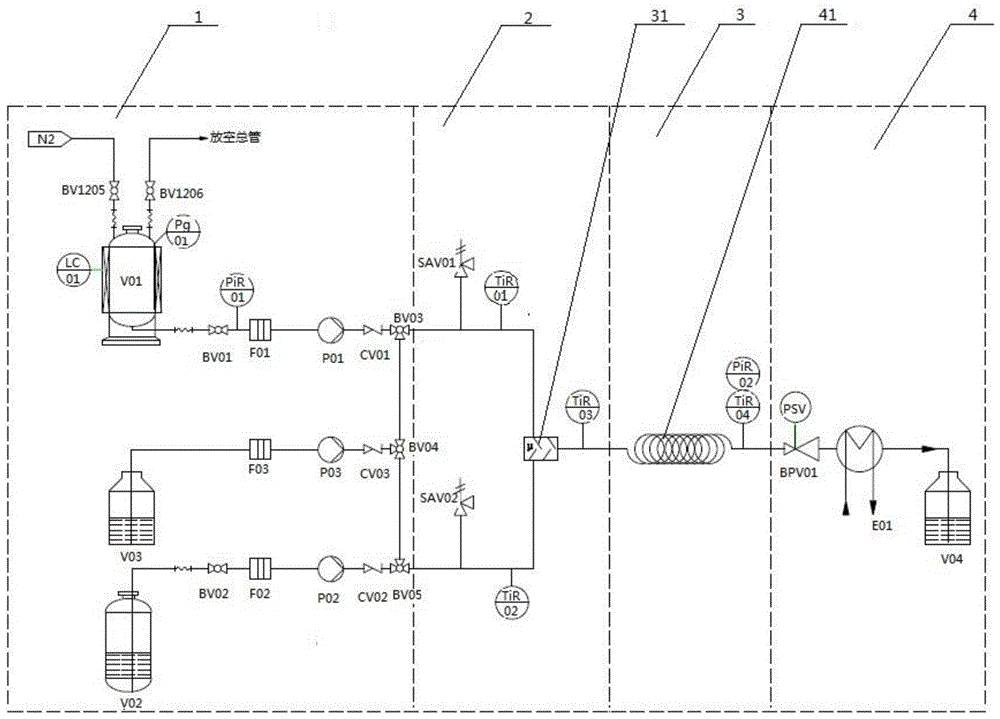

A kind of microreactor device and preparation process for producing 2-hydroxyethylhydrazine

A micro-reactor, hydroxyethyl hydrazine technology, applied in hydrazine preparation, organic chemistry and other directions, can solve the problems of amplification effect, large energy consumption, product quality decline, etc., achieve high heat transfer efficiency and heat transfer coefficient, speed up The effect of reducing the reaction rate and recycling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

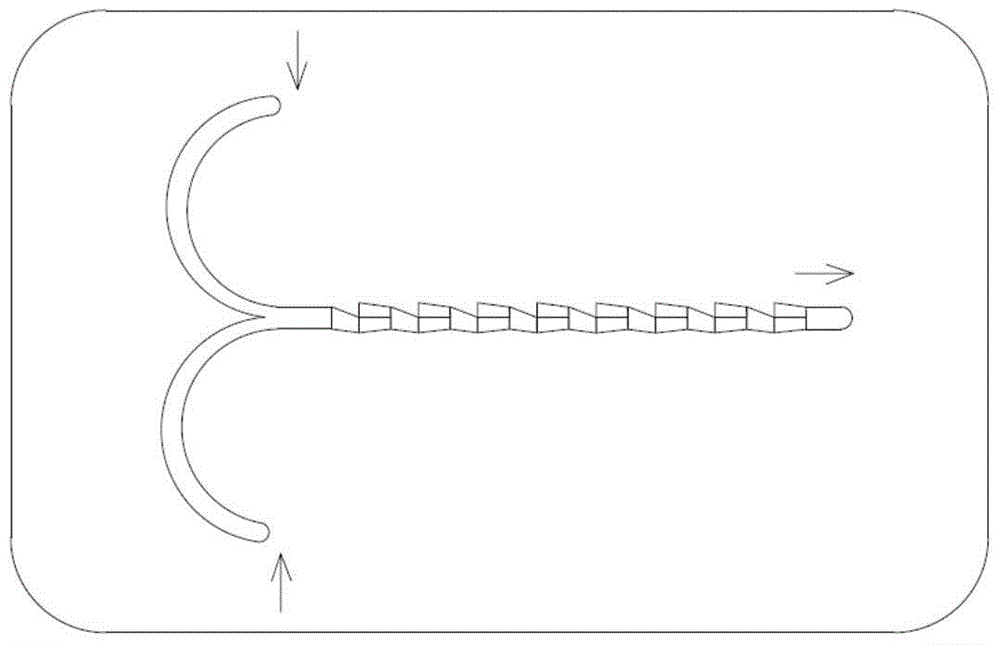

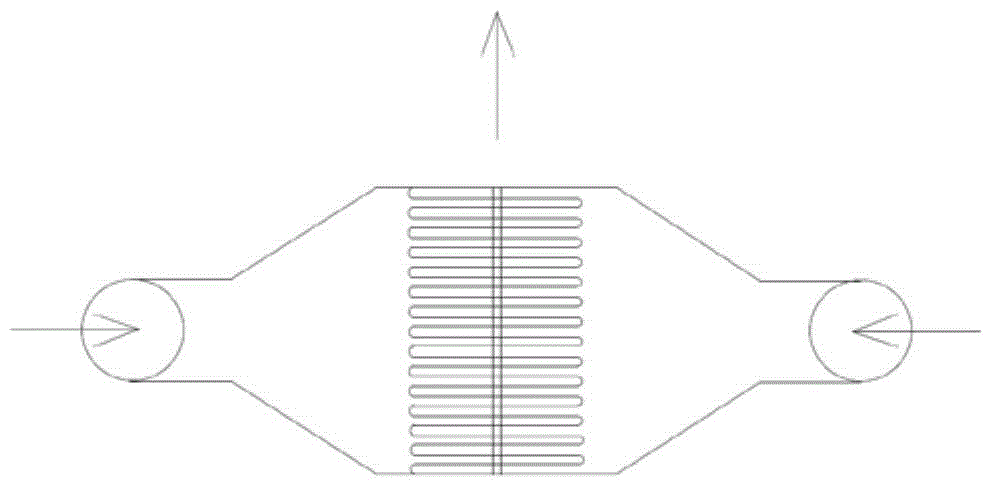

Embodiment 1

[0038] Ethylene oxide gas is liquefied and added to storage tank V01, pressurized to 1.0-1.5MPa with nitrogen, 80% hydrazine hydrate is added to storage tank V02, and the molar ratio of hydrazine hydrate and ethylene oxide is controlled to be 8:1. The feed is fed by feed pump P01 and feed pump P02 respectively, the total feed flow rate is 2.0L / h, the temperature of the micro-mixer is set to 40°C, the temperature of the split tube reactor is set to 60°C, and the temperature of the micro-heat exchanger is set to 0~10℃, the back pressure of the back pressure valve is 1.5~2.5MPa, the two feed liquids enter the CPMM-R300 micro-mixer to mix and further react in the split tube reactor, the reaction liquid cools down through the micro heat exchanger, and enters the receiving storage In the tank, most of the water and excess hydrazine hydrate were removed by distillation under reduced pressure to obtain 2-hydroxyethylhydrazine as a colorless oily liquid with a purity of 89.5% and a yiel...

Embodiment 2

[0040] The device process is the same as in Example 1, using a SIMM-V2 micro-mixer. The purity of the product 2-hydroxyethylhydrazine is 90.6%, and the yield is 96%.

Embodiment 3

[0042] The process of the device is the same as in Example 1, except that the total flow rate of the feed is changed to 80 L / h, and a Starlam 30 micro-mixer is used. The purity of the product 2-hydroxyethylhydrazine is 90.2%, and the yield is 94.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com