Method for rapidly preparing hydrophobic silica aerogel through subcritical drying of methanol

A technology of water silicon oxide and aerogel, applied in the directions of silicon oxide and silicon dioxide, can solve the problems of long preparation time, potential safety hazards, high energy consumption, etc., to save time and energy costs, ensure hydrophobicity, save energy The effect of the surface modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Sol-gel preparation: Mix 150 grams of methyl orthosilicate (28% wt) and 50 grams of methyl triethoxysilane, add 50 grams of deionized water, stir at a constant speed for about 10-40 minutes, and prepare a silicon solution Extract 500 grams of industrial methanol with a content of 99.5%, add it into the silicon solution prepared in the previous step at a uniform speed, drop into 1M hydrochloric acid aqueous solution after stirring, stir evenly, make the pH value reach about 2, and stir at a constant speed for 1 hour to fully hydrolyze. Then add 1M aqueous sodium hydroxide solution dropwise at 30°C to increase the pH value, stir evenly, and let stand for 10-60 minutes to form a gel. Subcritical drying can be performed after aging the gel at 50°C for 5 hours.

[0047] Subcritical drying: put the aged gel in an autoclave, immerse and close the autoclave with industrial methanol, slowly raise the temperature of the autoclave to about 190°C, and keep the pressure inside the a...

Embodiment 2

[0049] Sol-gel preparation: Take 100 grams of methyl orthosilicate (28%wt) and mix 25 grams of dimethyldiethoxysilane, add 20 grams of deionized water and stir at a constant speed for about 10-40 minutes, then prepare Silicon solution; extract 300 grams of industrial methanol with a content of 99.5%, add it into the silicon solution prepared in the previous step at a uniform speed, and then drop in 1M hydrochloric acid aqueous solution after stirring evenly, so that the pH value reaches about 2, and stir at a constant speed for 1 hour to fully hydrolysis. In an environment at 35°C, drop 1M ammonia solution to increase the pH value to 7.4, stir evenly to prepare a silica sol, inject the silica sol into a glass fiber blanket with a length, width, and thickness of 20cm, 20cm, and 1cm, and let it stand After about 10-60 minutes, the gel glass fiber composite blanket is made. Place the gel glass fiber composite blanket in an aging kettle at 50°C for 8 hours.

[0050] Subcritical ...

Embodiment 3

[0052] Sol-gel preparation: Mix 200 grams of ethyl orthosilicate (28%wt) and 50 grams of methyltriethoxysilane, add 25 grams of deionized water and stir at a constant speed for about 10-40 minutes, then prepare a silicon solution Extract 500 grams of industrial methanol with a content of 99.5%, add it into the silicon solution prepared in the previous step at a uniform speed, drop into 1M hydrochloric acid aqueous solution after stirring, stir evenly, make the pH value reach about 2, and stir at a constant speed for 1 hour to fully hydrolyze. Then add 1M aqueous sodium hydroxide solution dropwise at 30°C to increase the pH value, stir evenly, and let stand for 10-60 minutes to form a gel. Subcritical drying can be performed after aging the gel at 65°C for 4 hours.

[0053] Subcritical drying: put the aged gel in an autoclave, immerse and close the autoclave with industrial methanol, slowly raise the temperature of the autoclave to about 190°C, and keep the pressure inside the ...

PUM

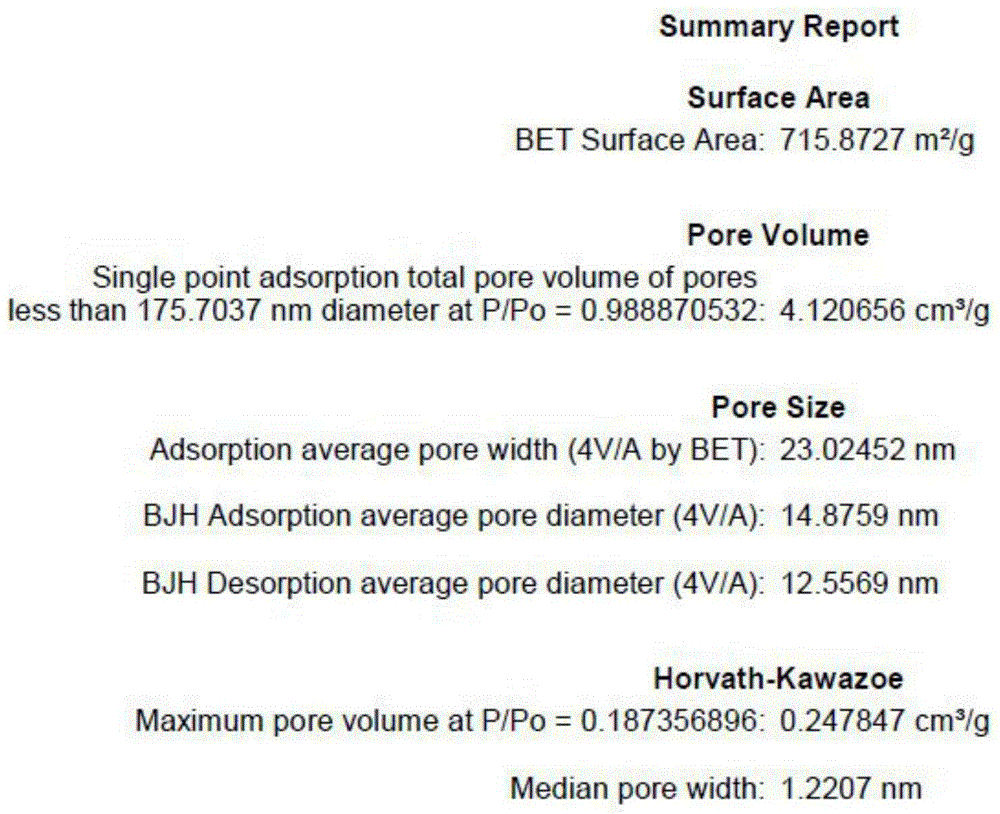

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com