Graphene preparation method

A graphene and inorganic salt technology, applied in the field of carbon-containing organic matter conversion non-gas phase growth graphene, to achieve the effects of high product purity, good dispersibility and short reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 7.325g of sodium citrate and 21.002g of sodium bicarbonate in a molar ratio of 1:10, put them into an agate mortar and grind them thoroughly and mix them evenly.

[0023] (2) Put the mixture obtained in the previous step into a high-temperature tube furnace, pass high-purity argon for 30 minutes to exhaust the residual air in the furnace tube, then heat it from room temperature to 900 °C at a heating rate of 3 °C / min, and keep it warm 1h, then naturally cool to room temperature, turn off the argon, and take out the black solid mixture of graphene and inorganic salt reaction medium.

[0024] (3) Put the solid mixture obtained in the previous step into the hydrochloric acid lotion and soak for 5 hours, separate by suction filtration, wash several times with deionized water and absolute ethanol, put it in a vacuum drying oven at 100°C and dry for 12 hours to obtain Graphene material.

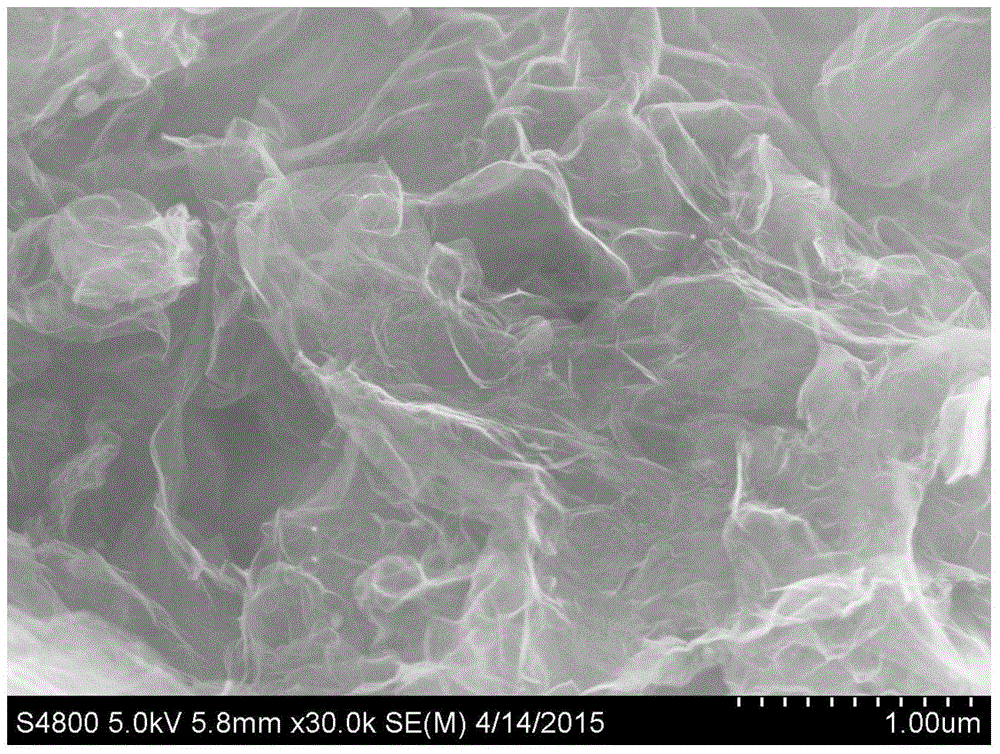

[0025] figure 1 It is a scanning electron microscope picture of the prepared...

Embodiment example 2

[0027] (1) Weigh 2.188g of sodium gluconate and 20.000g of calcium carbonate at a molar ratio of 1:20, put them into an agate mortar and grind them thoroughly and mix them evenly.

[0028] (2) Put the mixture obtained in the previous step into a high-temperature tube furnace, pass high-purity argon for 30 minutes to exhaust the residual air in the furnace tube, then heat it from room temperature to 700 °C at a heating rate of 5 °C / min, and keep it warm 5h, then naturally cooled to room temperature, closed the argon, and took out the black solid mixture of graphene and inorganic salt reaction medium.

[0029] (3) Put the solid mixture obtained in the previous step into the sulfuric acid lotion and soak for 5 hours, separate by suction filtration, wash several times with deionized water and absolute ethanol, put it in a vacuum drying oven at 100°C and dry for 12 hours to obtain Graphene material.

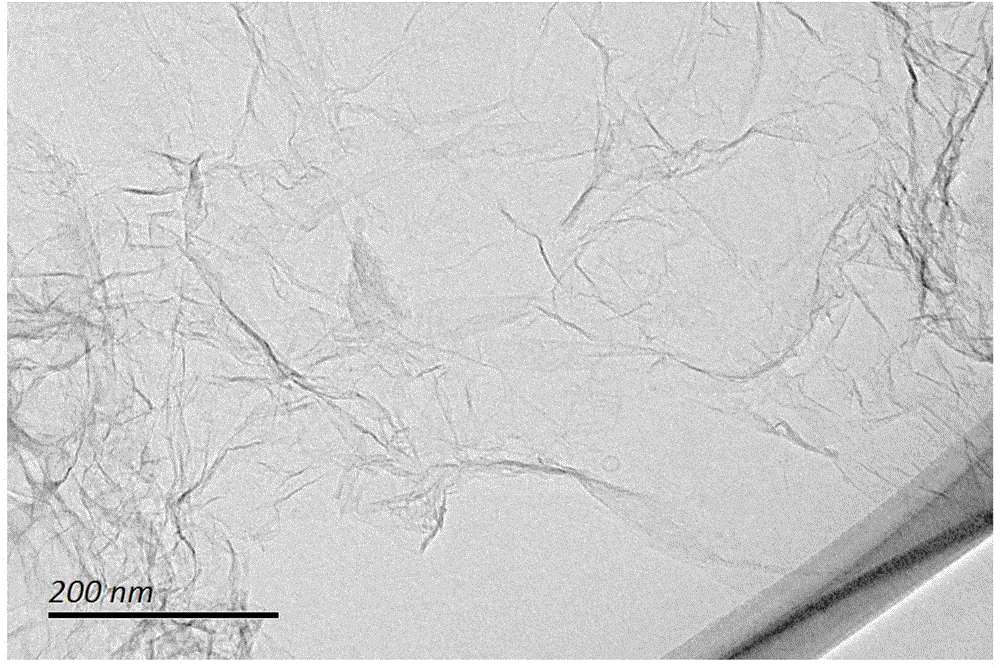

[0030] figure 2 It is a transmission electron microscope picture of the prepar...

Embodiment example 3

[0032] (1) Weigh 9.70g of starch and 27.26g of zinc chloride at a molar ratio of 1:4, put them into an agate mortar, grind them and mix them well.

[0033](2) Put the mixture obtained in the previous step into a high-temperature tube furnace, pass high-purity nitrogen gas for 30 minutes to exhaust the residual air in the furnace tube, then heat it from room temperature to 850°C at a heating rate of 10°C / min, and keep it warm for 3h , then cool naturally to room temperature, turn off the nitrogen, and take out the black solid mixture that obtains graphene and inorganic salt reaction medium.

[0034] (3) Put the solid mixture obtained in the previous step into the sulfuric acid lotion and soak for 5 hours, separate by suction filtration, wash several times with deionized water and absolute ethanol, put it in a vacuum drying oven at 100°C and dry for 12 hours to obtain Graphene material.

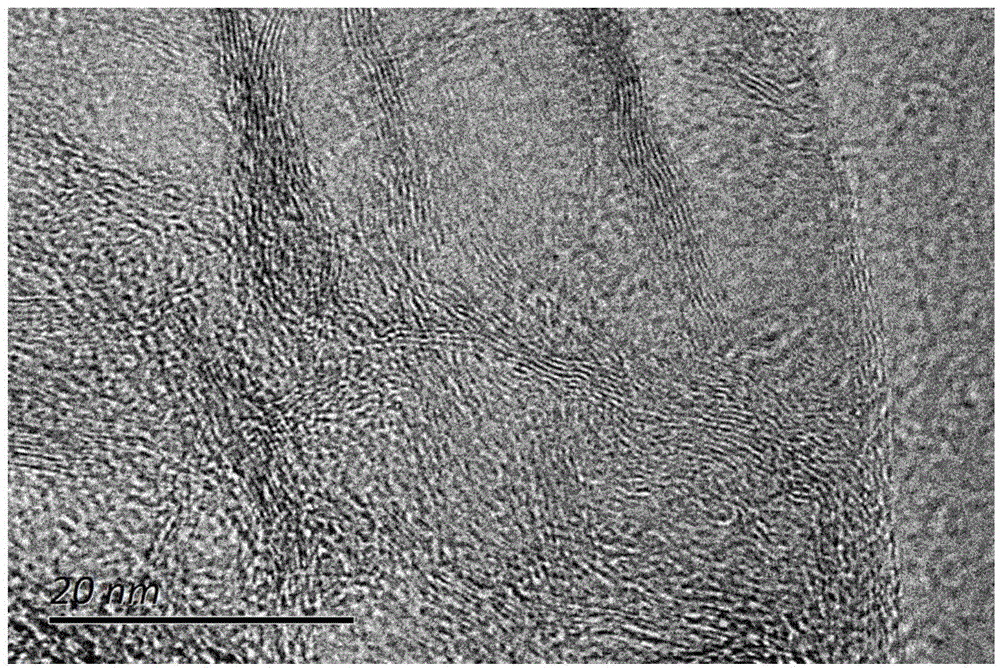

[0035] image 3 It is a high-resolution transmission electron microscope image of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com