Preparing method of simple substance bismuth/bismuth compound nanocomposite with oxygen vacancies

A technology for nanocomposite materials and bismuth compounds is applied in the field of one-step synthesis of elemental bismuth/bismuth compound nanocomposite materials containing oxygen vacancies, which can solve the problems of lack of universality, environmental pollution and high cost, and achieve large-scale production and reduce Production costs, avoid uncontrollable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

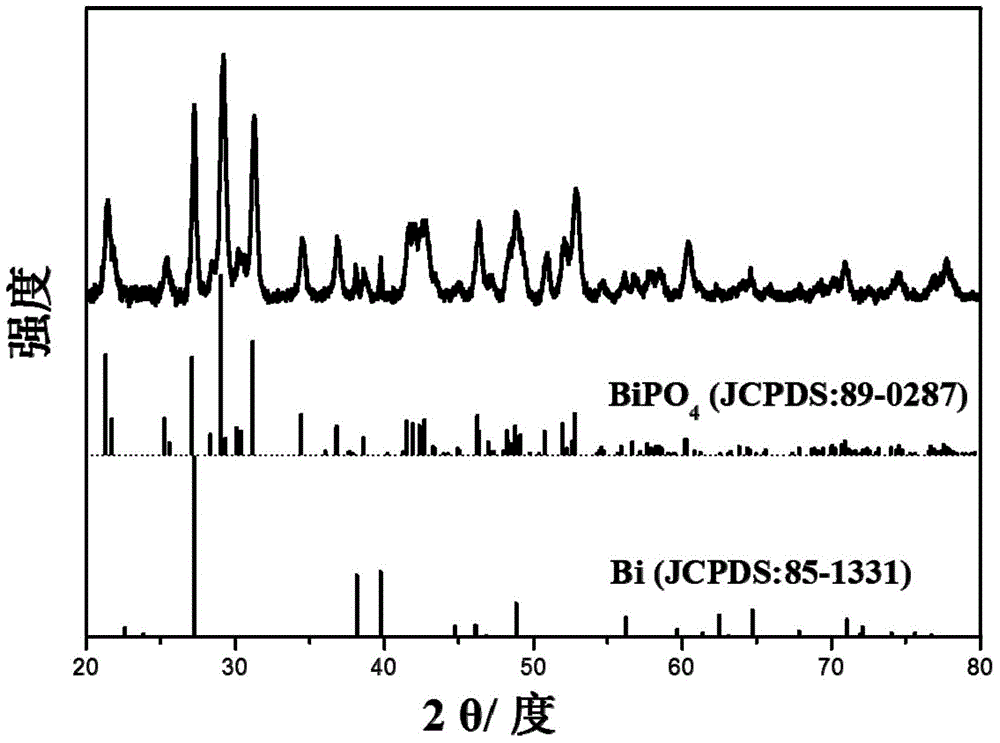

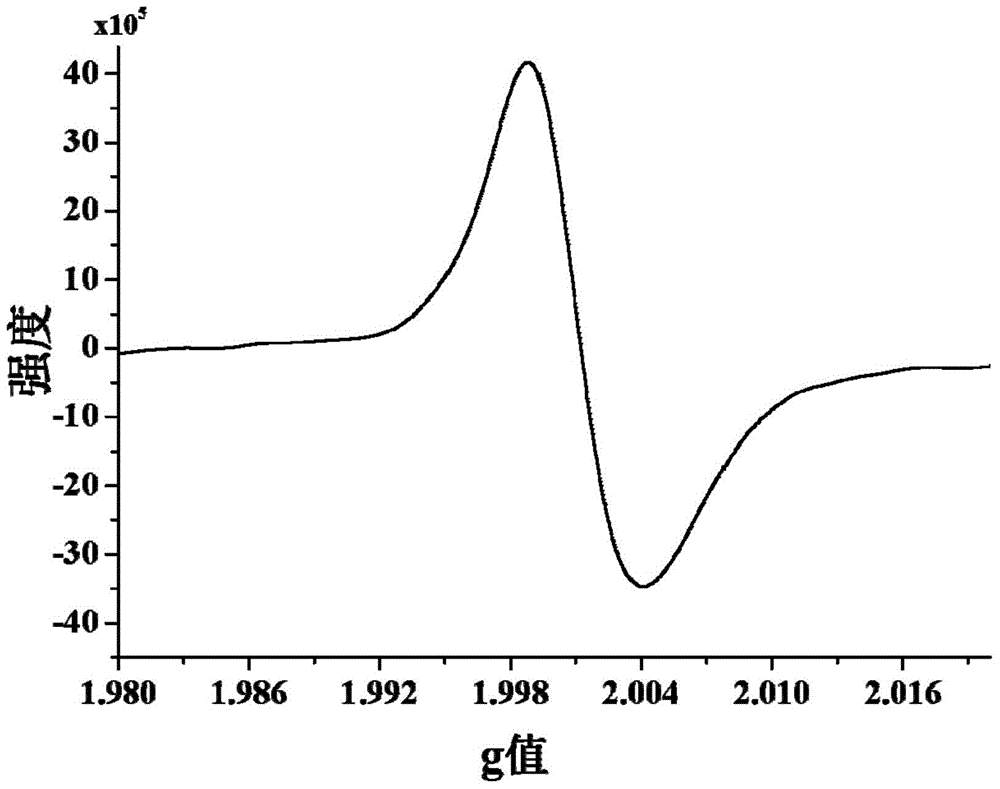

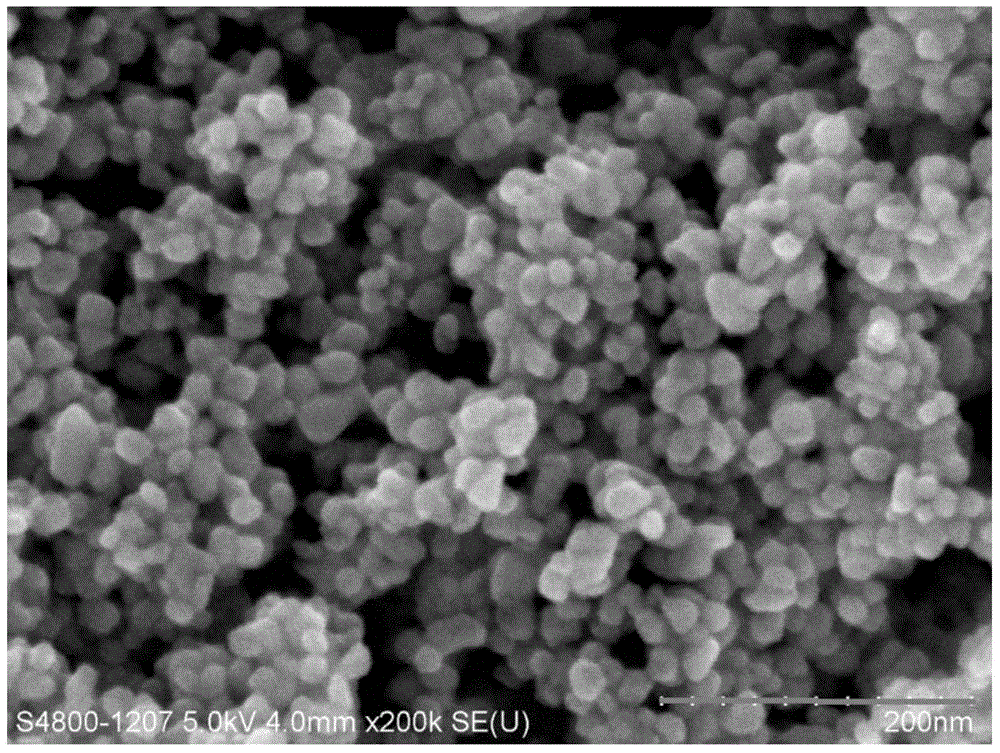

[0026] Embodiment 1 The preparation method of the elemental bismuth / bismuth phosphate nanocomposite material containing oxygen vacancies comprises the following steps:

[0027] Take 0.1mmol of bismuth nitrate pentahydrate, add 30mL of ethylene glycol, ultrasonically dissolve, then add 0.1mmol of sodium tripolyphosphate to the above solution; the reaction solution is placed in a stainless steel autoclave lined with polytetrafluoroethylene. React at 180°C for 12 hours; remove residual solutes and solvents by centrifugal washing, dry the product at 60°C for 12 hours, and obtain elemental bismuth / bismuth phosphate nanocomposites containing oxygen vacancies after cooling.

Embodiment 2

[0028] Embodiment 2 The preparation method of the elemental bismuth / bismuth phosphate nanocomposite material containing oxygen vacancies, comprising the following steps:

[0029] Take 0.33mmol of bismuth nitrate pentahydrate, add 30mL of ethylene glycol, ultrasonically dissolve, then add 0.33mmol of sodium tripolyphosphate to the above solution; the reaction solution is placed in a stainless steel autoclave lined with polytetrafluoroethylene. React at 180°C for 12 hours; remove residual solutes and solvents by centrifugal washing, dry the product at 60°C for 12 hours, and obtain elemental bismuth / bismuth phosphate nanocomposites containing oxygen vacancies after cooling.

Embodiment 3

[0030] Embodiment 3 The preparation method of the elemental bismuth / bismuth phosphate nanocomposite material containing oxygen vacancies, comprising the following steps:

[0031] Take 0.33mmol of bismuth nitrate pentahydrate, add 30mL of ethylene glycol, ultrasonically dissolve, then add 0.33mmol of sodium tripolyphosphate to the above solution; the reaction solution is placed in a stainless steel autoclave lined with polytetrafluoroethylene. React at 180°C for 24 hours; remove residual solutes and solvents by centrifugal washing, dry the product at 60°C for 12 hours, and obtain elemental bismuth / bismuth phosphate nanocomposites containing oxygen vacancies after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com