Method for producing stalks by expanded stems

A technology for expanding tobacco stems and cut stems, which is applied in the fields of tobacco, tobacco processing, and application, can solve the problems of low yield of cut stems, small slice cross-section and small volume of tobacco stems, and achieves high purity of cut stems and improved quality. The effect of high rate and whole yarn rate, good suction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

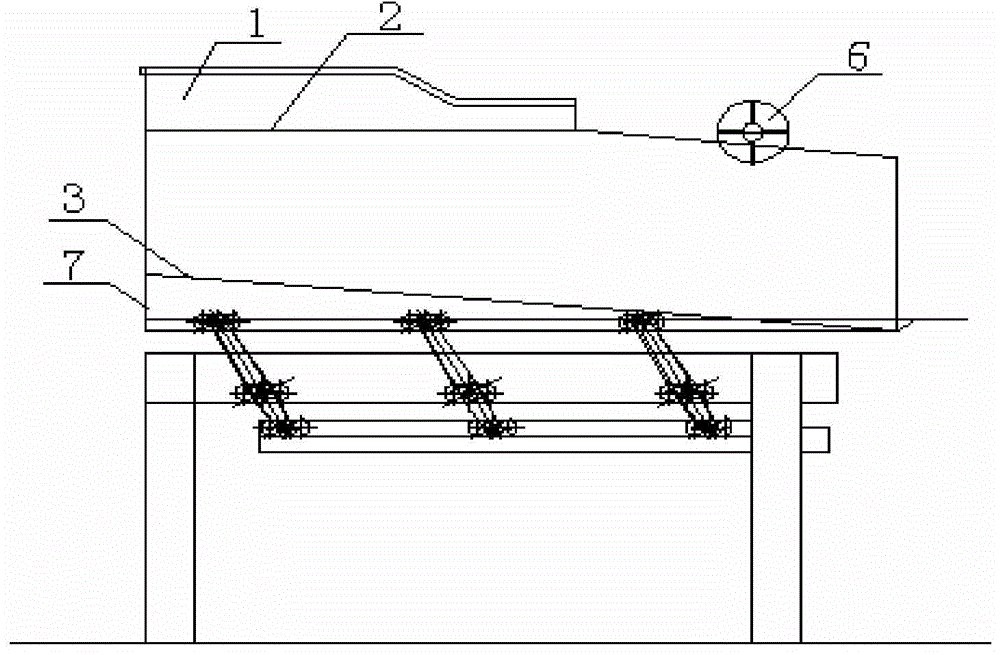

[0126] Example 1: Making Cut Stems Using Expanded Tobacco Stems

[0127] The implementation steps of this embodiment are as follows:

[0128] A. Pretreatment of expanded tobacco stems

[0129] Use tobacco stem conveying equipment to send the expanded tobacco stems obtained by superheated steam-microwave co-processing to the dampening equipment sold by Qinhuangdao Tobacco Machinery Co., Ltd. under the trade name of JG3 Stem Impregnating Machine, under the condition of water temperature of 48 ℃ Moisture treatment, so that the moisture content of the expanded tobacco stems reaches 36% by weight; then the moisture-restored expanded tobacco stems are delivered to a stem storage cabinet sold by Kunming Shipbuilding Equipment Group Co., Ltd. under the trade name YA7310 type storage cabinet at 22 ° C. Store the stems under the condition of relative humidity of 65%, so that the penetration rate of the expanded tobacco stems can reach 98.2%;

[0130] B. Stemming and slicing

[0131] ...

Embodiment 2

[0141] Example 2: Making Cut Stems Using Expanded Tobacco Stems

[0142] The implementation steps of this embodiment are as follows:

[0143] A. Pretreatment of expanded tobacco stems

[0144] Use the tobacco stem conveying equipment to send the expanded tobacco stems obtained by the solid medium-microwave expansion process to the dampening equipment sold by the branch company of the Xuzhou Machinery Factory of the Ministry of Railways under the trade name YJG6 stem washing machine, under the condition that the water temperature is 40°C carry out moisture regaining treatment under the condition that the moisture content of the expanded tobacco stem reaches 28% by weight; Store the stems under the conditions of 20°C and 55% relative humidity, so that the penetration rate of the expanded tobacco stems can reach 98.6%;

[0145] B. Stemming and slicing

[0146] The expanded tobacco stems obtained in step A are straightened out using the device for straightening the stems of the...

Embodiment 3

[0156] Example 3: Making Cut Stems Using Expanded Tobacco Stems

[0157] The implementation steps of this embodiment are as follows:

[0158] A. Pretreatment of expanded tobacco stems

[0159] Use the tobacco stem conveying equipment to send the expanded tobacco stems obtained by the puffing agent expansion process to the moisture regaining equipment sold by Jiangsu Zhisi Machinery Manufacturing Co., Ltd. under the trade name WQ4302 sink type stem washer. Moisture treatment is carried out so that the moisture content of the expanded tobacco stem reaches 30% by weight; then the moisture-restored expanded tobacco stem is sent to a stem storage cabinet sold by Jiangsu Zhisi Machinery Manufacturing Co., Ltd. under the trade name GPT15 type stem storage cabinet. Store the stems under the conditions of 24°C and 62% relative humidity, so that the penetration rate of the expanded tobacco stems can reach 99.0%;

[0160] B. Stemming and slicing

[0161] The expanded tobacco stems obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com