Process for producing oil

A technology for oil recovery and residual oil, which can be used in chemical instruments and methods, earthwork drilling, drilling composition, etc., and can solve problems such as difficulty in oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

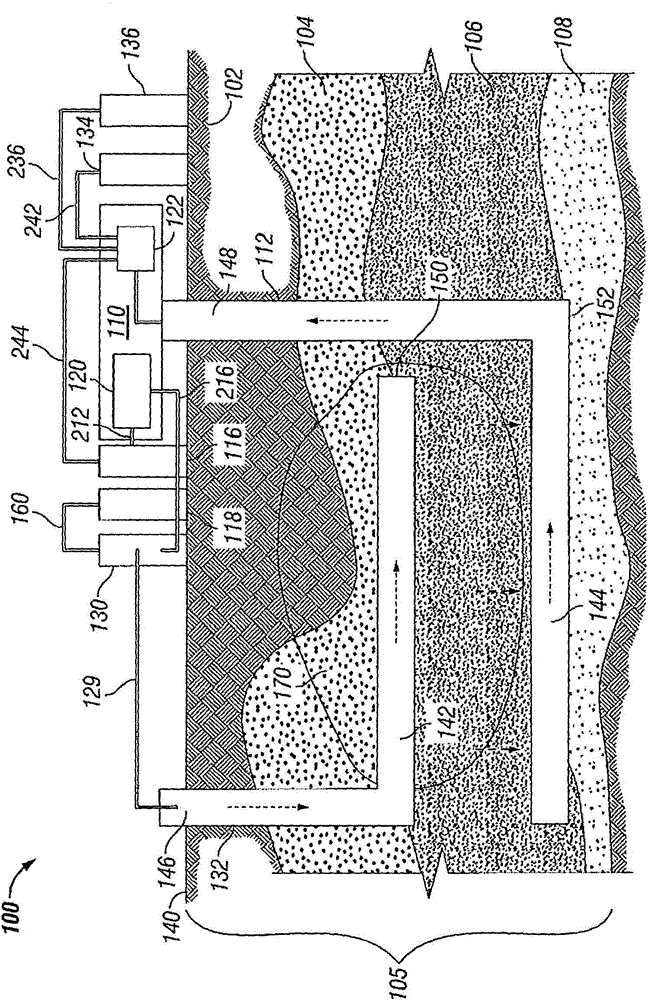

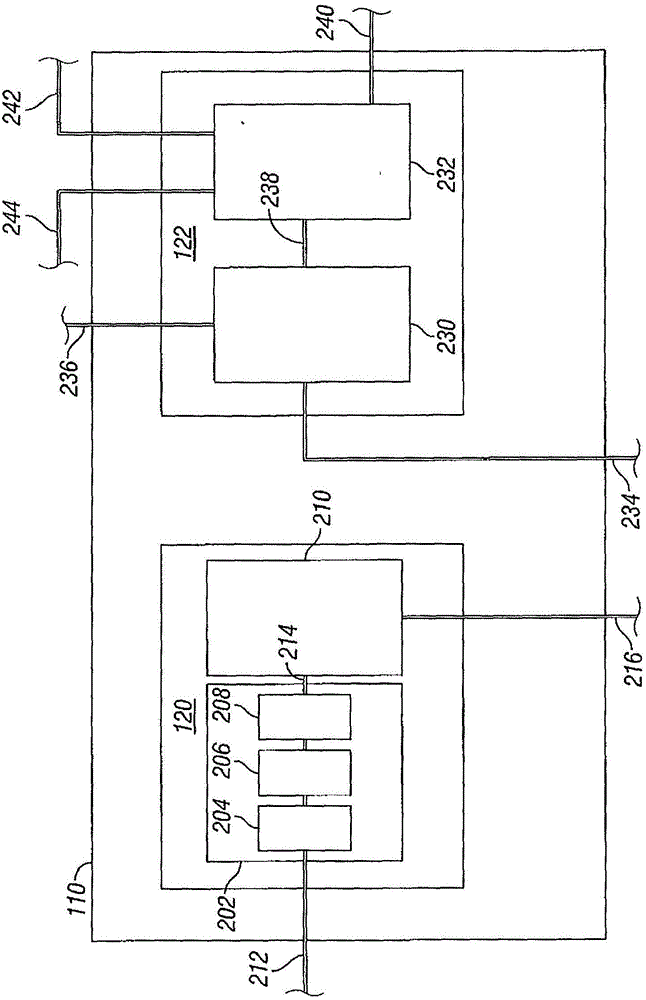

[0019] The present invention relates to a method of enhancing oil recovery from subterranean formations containing heavy oil or bitumen. An oil recovery formulation comprising ammonia and low quality steam (particularly steam with a mass gas fraction less than 0.7) can be injected into a formation from which oil can be produced after injecting the oil recovery formulation into the formation. The combination of ammonia and low quality steam in the oil recovery formulation produces ammonium hydroxide in the liquid phase aqueous condensate portion of the low quality steam, so that ammonium hydroxide is present in the oil recovery formulation when the oil recovery formulation is injected into the formation. preparation. Ammonium hydroxide can react with petroleum acids (such as naphthenic acid) in bitumen or heavy oil in the immediate vicinity of injection wells to form oil emulsifying soaps that promote the formation of oil-in-water emulsions with condensed water from steam, Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com