Leaching and recycling method for metals in anode waste materials of lithium-ion batteries

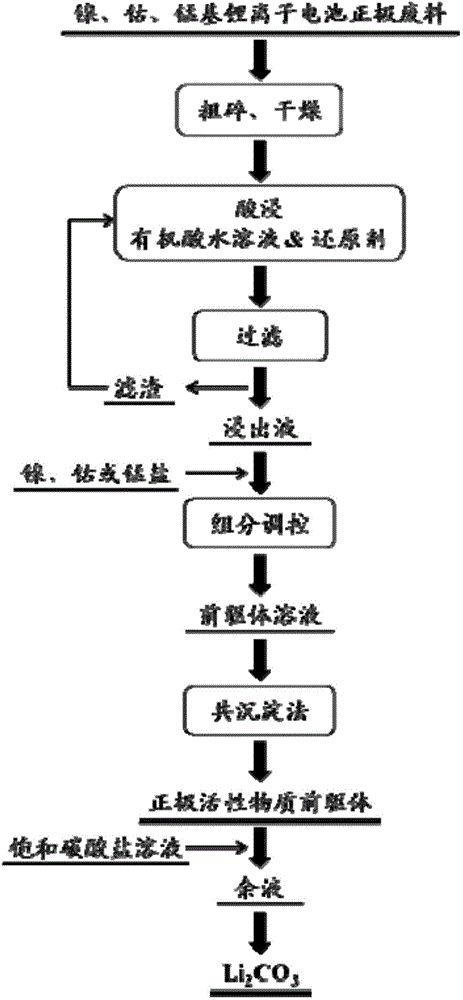

A technology for lithium-ion batteries and cathode materials, which is applied in the field of leaching metals from lithium-ion battery cathode waste, can solve the problems of lack of recovery technology for cathode waste and mixed cathode waste, and the failure to realize closed-loop circulation of metal components, etc., to achieve a wide range of applications , The leaching time is short, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] The specific steps of the recycling method of lithium ion battery cathode waste based on metal closed-loop cycle are as follows:

[0102] (1) Take 30g of positive electrode waste generated in the production process of lithium-ion battery ternary composite positive electrode material nickel cobalt lithium manganate, first cut it into positive electrode waste fragments of about 10mm × 10mm, and then place these fragments in a drying oven at 65°C Dry at a constant temperature for 24 h, and measure the composition and content of metal elements in the dried cathode waste. The results are shown in Table 1.

[0103] Table 1 The mass percentage of metals in the dried nickel-cobalt lithium manganate cathode waste

[0104] Metal

Ni

Co

Mn

Li

Al

Mass content (wt.%)

18.32

18.65

17.57

6.15

7.86

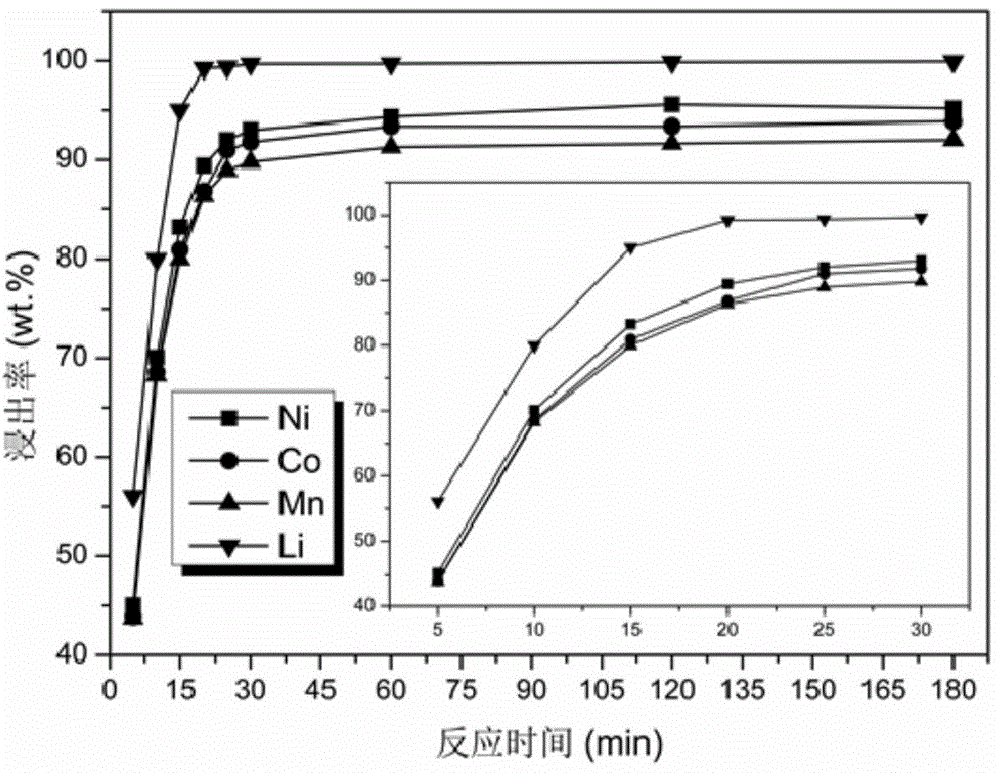

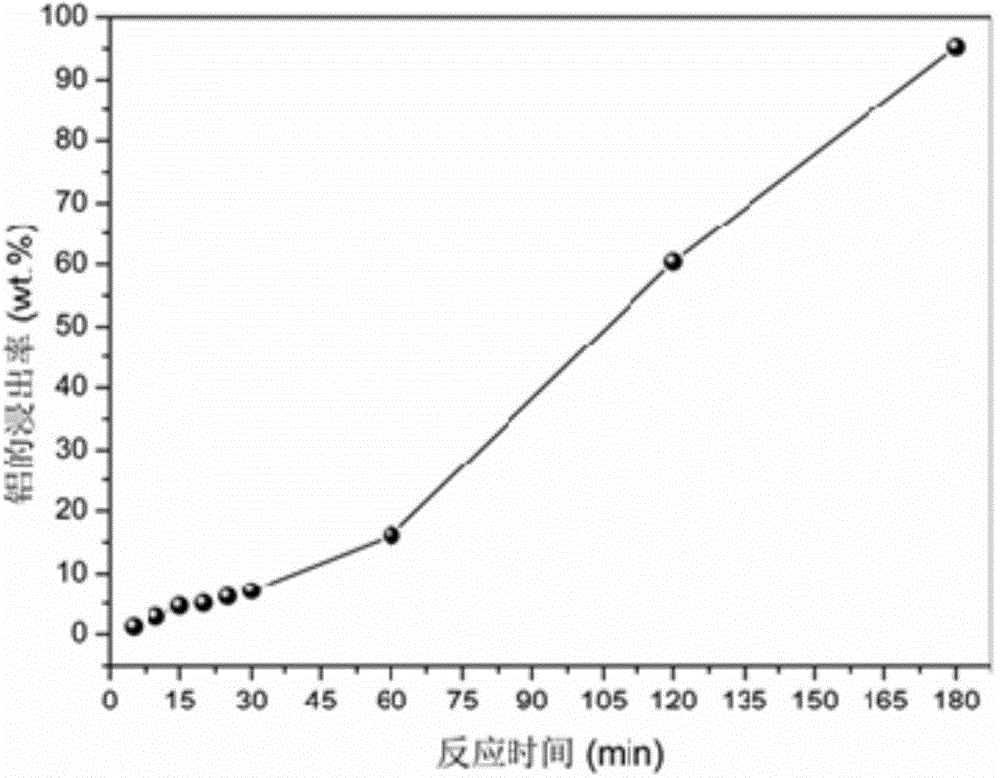

[0105] (2) respectively take 9 parts of the dried positive waste scraps obtained by step (1) with a mass of about 2.5g, respe...

Embodiment 2

[0115] The specific steps of the recycling method of lithium ion battery cathode waste based on metal closed-loop cycle are as follows:

[0116] (1) Respectively take the lithium cobalt oxide (LiCoO) separated from the lithium ion battery 2 ) positive electrode waste 10g and lithium nickel manganate (LiNi 1 / 2 Mn 1 / 2 O 2 ) 20g of positive electrode waste, their size is about 5mm~15mm×5mm~15mm, mix them evenly and dry them at a constant temperature in a drying oven at 130°C for 12h to obtain a dried mixed positive electrode waste, measure the metal in the dried mixed positive electrode waste The composition and content of the elements are shown in Table 3.

[0117] Table 3 The mass percentage of metals in the mixed cathode waste after drying

[0118] Metal

Ni

Co

Mn

Li

Al

Mass content (wt.%)

19.21

17.83

18.92

6.95

10.71

[0119] (2) respectively get 9 parts of the mixed positive waste waste after drying obtained...

Embodiment 3

[0128] The specific steps of the recycling method of lithium ion battery cathode waste based on metal closed-loop cycle are as follows:

[0129] (1) Take the nickel-cobalt lithium manganate (LiNi) separated from the lithium-ion battery. x Co y Mn l–x–y O 2 ) Positive electrode waste 30g, the size is about 10mm × 15mm, dried at a constant temperature in a 200 ℃ drying oven for 6h, to obtain a dried mixed positive electrode waste, measure the composition and content of metals in the dried mixed positive electrode waste, and the results are shown in Table 5. Show.

[0130] Table 5 The mass percentage of metals in the mixed cathode waste after drying

[0131] Metal

Ni

Co

Mn

Li

Al

Mass content (wt.%)

20.13

18.79

19.25

7.03

8.22

[0132] (2) Take the dried positive waste material obtained by step (1) with a mass of about 2.0 g and add it to a conical flask containing 50 mL of a mixed aqueous solution of formic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com