Front projection screen for ultra-short-throw projection and its preparation method and application

An ultra-short-focus, projection technology, applied in optics, instruments, projection devices, etc., can solve the problems of low gain and anti-ambient light ability, high cost, anti-ambient light ability, unattainable color uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

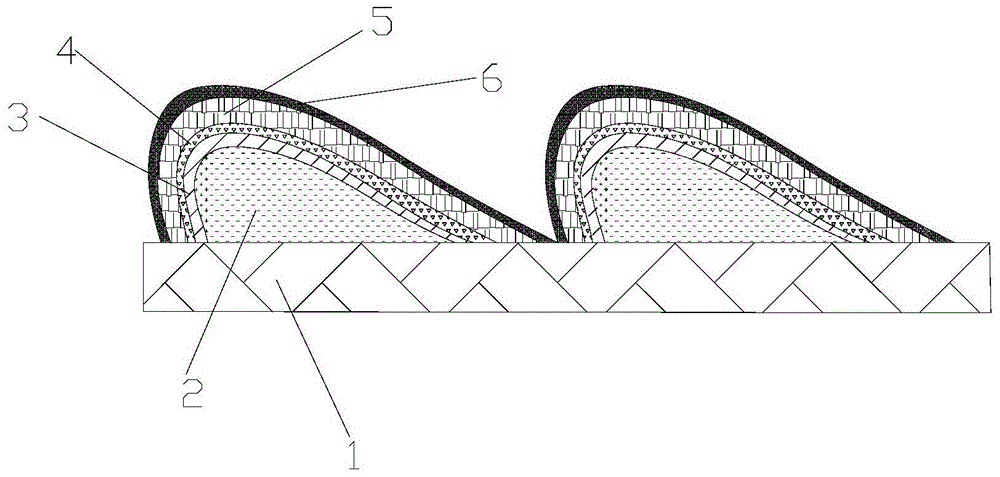

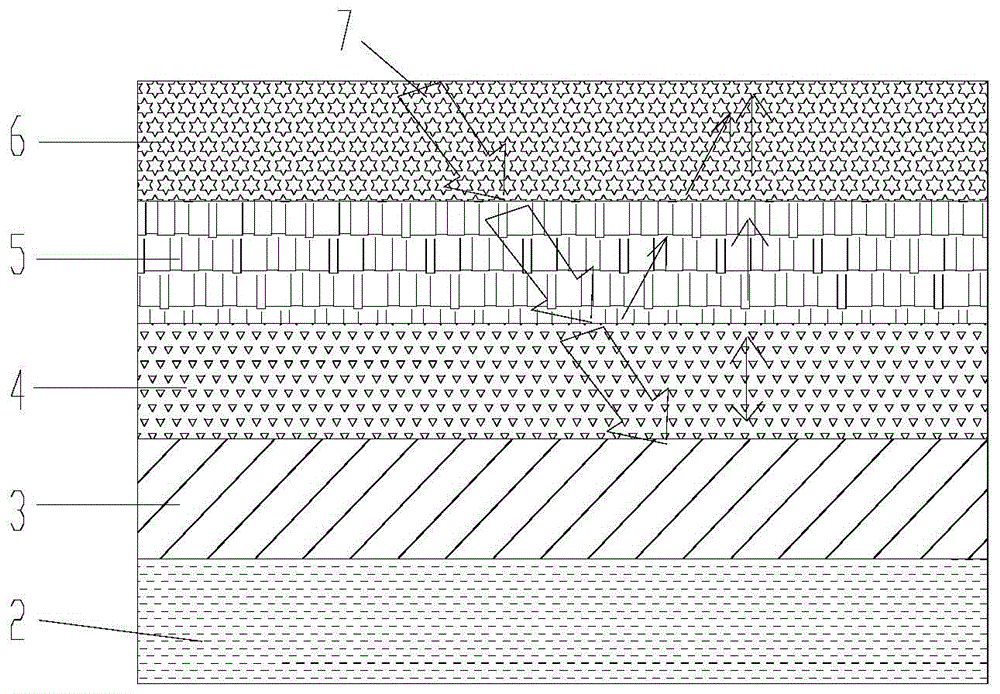

[0022] A front projection screen for ultra-short-focus projection, including a planar basic curtain base 1, and raised strips arranged side by side on the basic curtain base. The raised strips form a structural curtain from the inside to the outside. base 2, curtain base color filter layer 3, high light reflection layer 4, ion layer 5 and speckle filter layer 6.

[0023]Choose glass for structural processing to make a planar basic curtain base 1; use methacrylate, carbonate, stearic acid, and phosphor to form a mixture at a mass ratio of 30:1:0.5:0.1, and then directly Utilize the mold of outer circular arc structure on the basic curtain base 1 (the arc length of the outer circular arc is one-third of the circumference of the circle whose diameter is the line segment at the intersection of the section and the basic curtain base), and the mixture is cast to form the structural curtain Base 2, the molding temperature is 70°C; select saturated resin Ashland M105, spray directly o...

Embodiment 2

[0032] A front projection screen for ultra-short-focus projection, including a planar basic curtain base 1, and raised strips arranged side by side on the basic curtain base. The raised strips form a structural curtain from the inside to the outside. base 2, curtain base color filter layer 3, high light reflection layer 4, ion layer 5 and speckle filter layer 6.

[0033] Select polyvinyl chloride for structural processing to make a planar basic curtain base 1; use methacrylate, carbonate, stearic acid, and phosphor to form a mixture at a mass ratio of 30:1:0.5:0.1, and then Directly on the base curtain base 1, use the mold of the outer arc structure (the arc length of the outer arc is one-third of the circumference of the circle whose diameter is the line segment at the intersection of the cross section and the base curtain base), and cast the mixture to form Structural curtain base 2, the molding temperature is 70°C; select saturated resin Ashland M105, spray directly on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com