Flexible gas sensor based on three-dimensional net structured sensitive film and preparation method of flexible gas sensor

A gas sensor and network structure technology, which is applied in the fields of sensitive electronics and flexible electronics, can solve the problems of not taking advantage of the ductility of flexible substrates on three-dimensional network structure films, complex preparation processes, etc., and achieve rapid and high-sensitivity detection and preparation methods Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the above-mentioned flexible gas sensor based on the three-dimensional network structure sensitive film proposed by the present invention comprises the following steps:

[0034] 1) Expose and develop the interdigitated electrode pattern on the flexible substrate layer 1 by photolithography; spin-coat photoresist on the front, 3000-5000rpm, 30-60s; pre-bake at 100-120°C, 1-3min; expose for 3-5s; develop; Post-bake at 100-120°C for 10-15 minutes, and set aside; the exposed part is the interdigitated electrode;

[0035] 2) Electron beam evaporation is used to sequentially evaporate chromium (Cr) / gold (Au) or titanium (Ti) / gold (Au) electrodes on the silicon oxide insulating layer, and chromium (Cr) / gold (Au) or titanium (Ti) ) / gold thicknesses are 10-30nm and 50-100nm respectively;

[0036] 3) Put the sample obtained above into an acetone solution, ultrasonically peel off the photoresist; wash with alcohol and deionized water in sequence, and blo...

Embodiment 1

[0040] Embodiment 1 is a typical example of the content of the present invention.

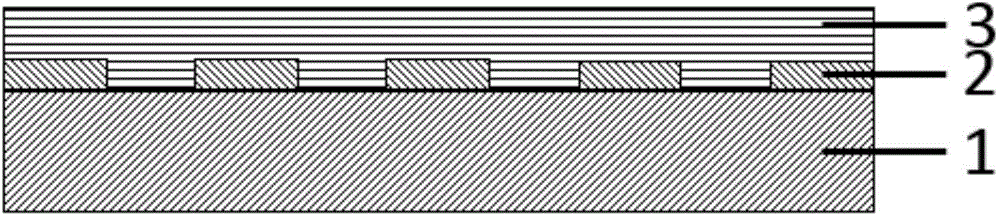

[0041] The flexible gas sensor element based on the three-dimensional network structure sensitive film of the present embodiment, such as figure 1 As shown, it includes a flexible substrate 1, an interdigital electrode layer 2, and a three-dimensional network structure sensitive thin film layer 3. Among them, the thickness of the flexible substrate 1 used is 100-200um, and the light transmittance is ≥70-80%. The material used in the flexible substrate is polyethylene terephthalate plastic (PET); the interdigital electrode layer 2 is made of chromium (Cr ) / gold (Au), the thickness is 10nm / 50nm; or titanium (Ti) / gold (Au), the thickness is 10nm / 50nm; , sheets, etc.) of metal oxide semiconductor materials are deposited by spraying to form a three-dimensional network structure sensitive thin film layer.

[0042] The technological process of the present embodiment is:

[0043] 1) For flexible PET...

Embodiment 2

[0049] Embodiment 2 is a typical example of the content of the present invention.

[0050] The flexible gas sensor element based on the three-dimensional network structure sensitive film of the present embodiment, such as figure 1 As shown, it includes a flexible substrate 1, an interdigital electrode layer 2, and a three-dimensional network structure sensitive thin film layer 3. Among them, the thickness of the flexible substrate 1 used is 100-200um, the light transmittance is ≥70-80%, and the material used for the substrate is polyimide (PI); the interdigital electrode layer 2 is made of chromium (Cr) / gold ( Au), the thickness is successively 30nm / 100nm; or titanium (Ti) / gold (Au), the thickness is successively 30nm / 100nm; three-dimensional network structure sensitive thin film layer 3 is to adopt carbon nanotube, adopt spraying method to deposit and form three-dimensional network structure sensitive film layer.

[0051] The technological process of the present embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com