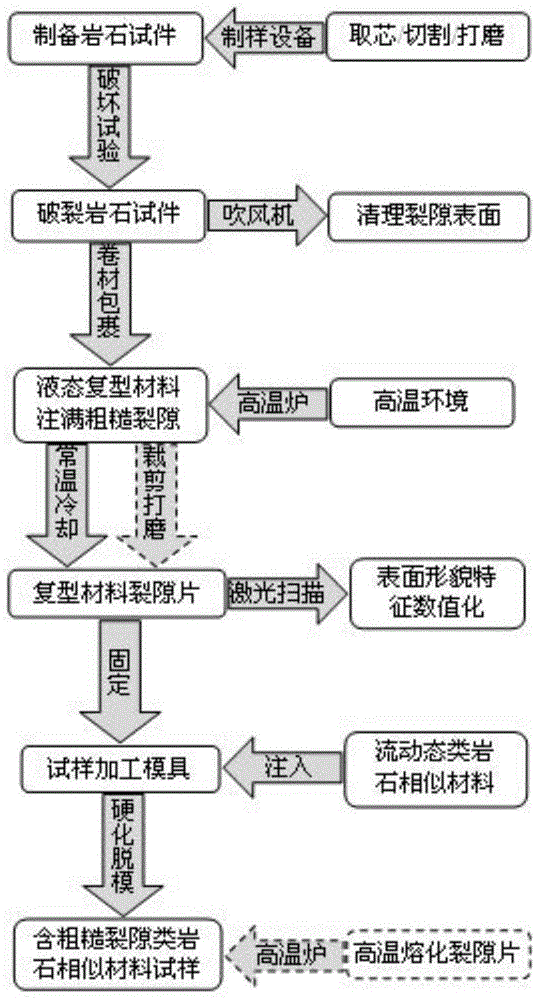

Method for prefabricating rough fractures in rocklike similar material specimen

A technology of rock similarity and rock test pieces, applied in the preparation of test samples, etc., can solve the problems of cracks that are difficult to repeat accurately, and achieve the effects of low cost, simple processing procedures, and convenient accurate quantification and comparative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Use a coring machine to take samples from the collected rocks, and obtain a standard cylindrical sample through cutting, grinding and other processes

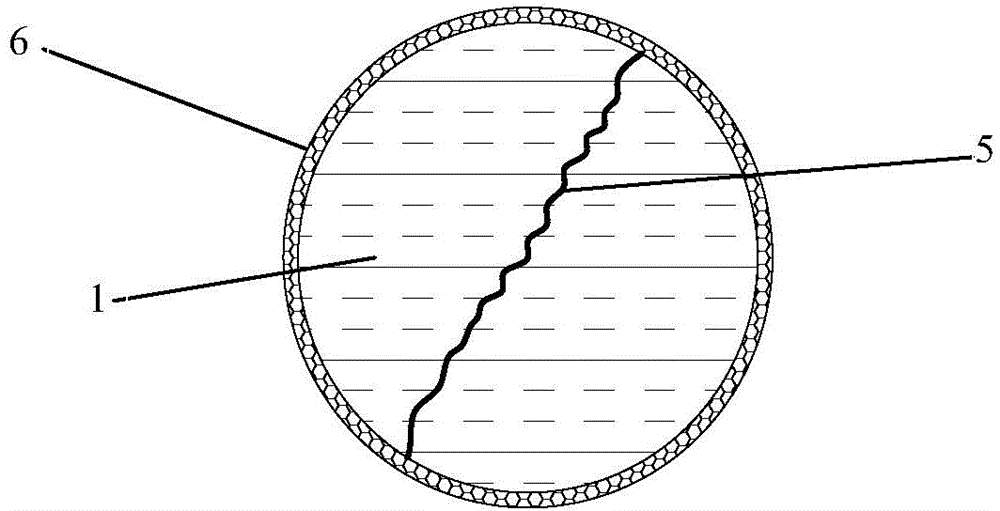

[0057] (2) A fractured rock sample 1 containing a single penetrating rough crack 5 is obtained through an angle die compression shear test;

[0058] (3) Cut the aluminum foil paper 6 into a rectangle of 170mm×100mm and a circle with a diameter of 60mm, wrap the side of the cracked cylindrical sample with rectangular aluminum foil, keep the opening of the cracked surface at 2mm, wrap the circle with high temperature resistant glue Paste the aluminum foil paper on the lower surface of the sample, and paste the overlapping parts of the aluminum foil paper together to ensure a good seal;

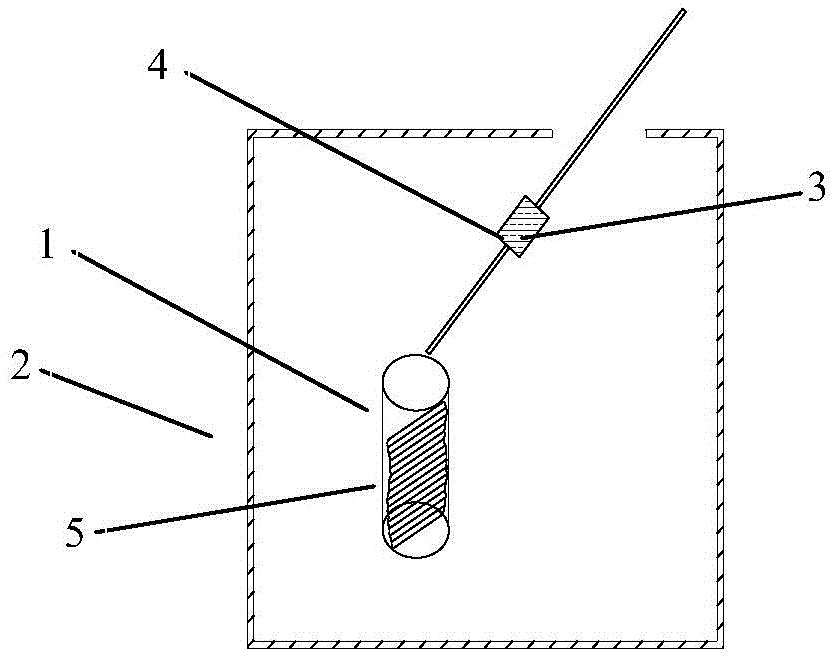

[0059] (4) Put the cylindrical sample wrapped by aluminum foil into the box-type high-temperature furnace 2 and heat to 240°C;

[0060] (5) Use a high-temperature furnace to melt metal tin into a liquid state with a melting point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com