Silent chain

一种无声链、链条的技术,应用在无声链领域,能够解决噪音、冲击性接触、摩擦损失等问题,达到防止摩擦损失及噪音、避免冲击性接触、缩小间隙的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

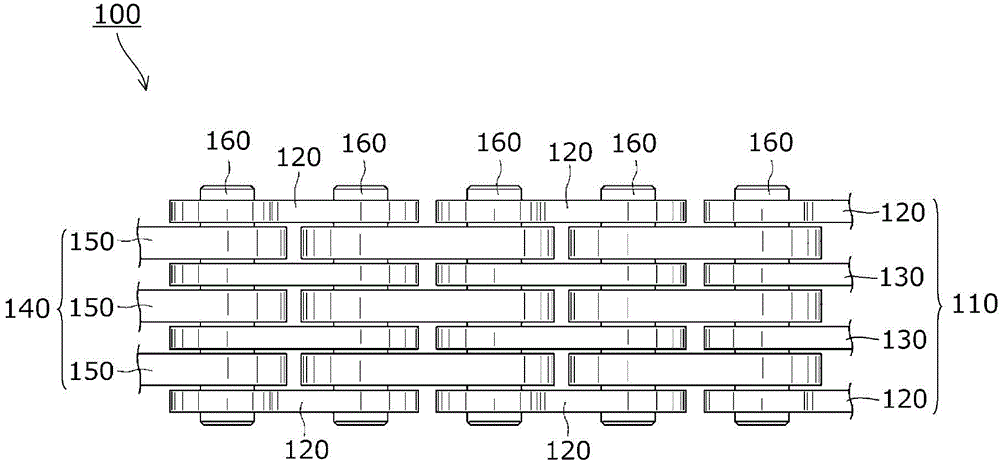

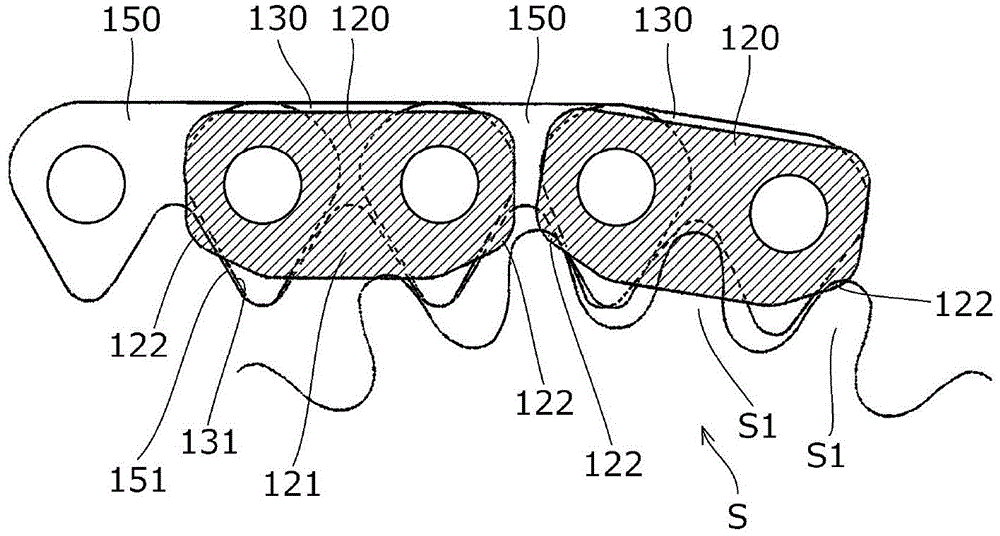

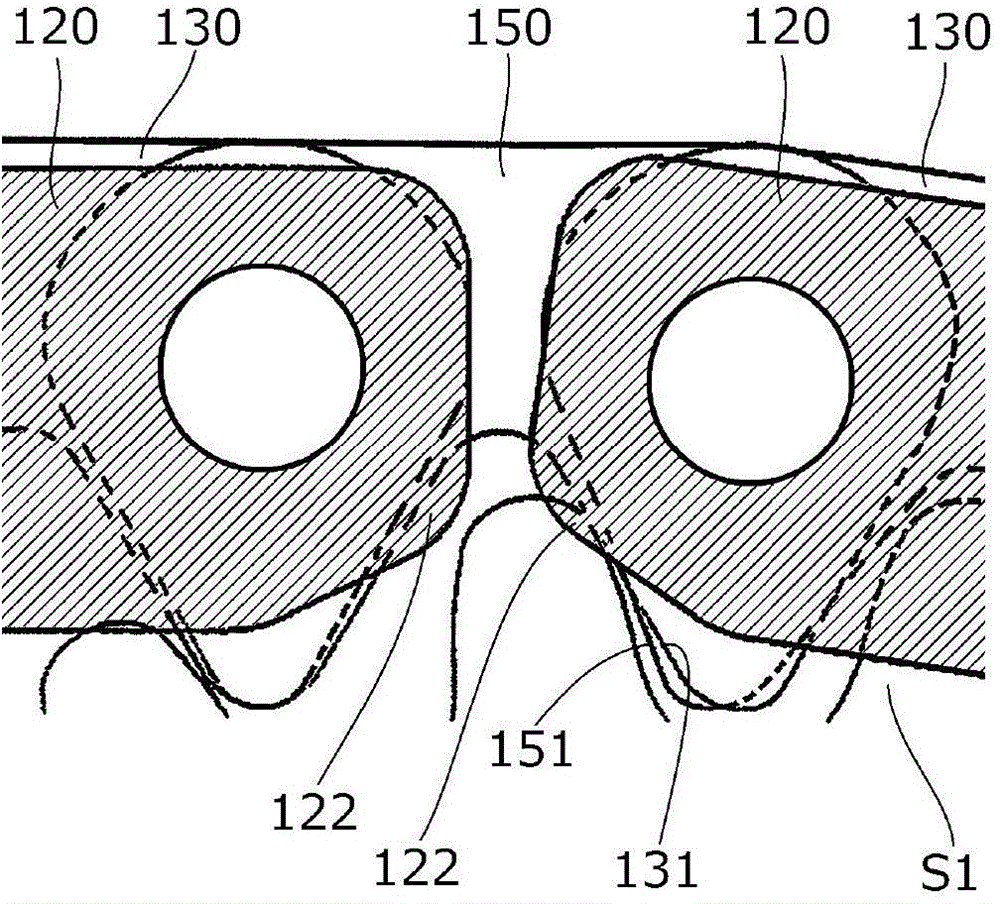

[0023] Below, according to Figure 1 ~ Figure 3 The silent chain 100 according to the first embodiment of the present invention will be described.

[0024] The silent chain 100 is configured as a timing chain installed in a timing system for an automobile engine, is wound around a plurality of sprockets S, and moves on a predetermined track. The silent chain transmission device is formed by the silent chain 100 and the sprocket S.

[0025] Such as figure 1 As shown, in the silent chain 100 , a plurality of guide rows 110 and a plurality of non-guide rows 140 are arranged alternately with half a pitch shifted in the chain length direction, and are flexibly connected by connecting pins 160 .

[0026] Such as figure 1 As shown, the guide row 110 is composed of a pair of left and right guide plates 120 arranged on both outer sides in the width direction of the chain, and a plurality of intermediate plates 130 arranged between the pair of left and right guide plates 120 . The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com