A local natural vibration disc opener with three-way spline curve fitting teeth

A technology of disc openers and spline curves, applied in the fields of excavation/covering trenches, planting methods, applications, etc., which can solve problems such as bulky machines, reduced trenching quality, and affecting seed emergence and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

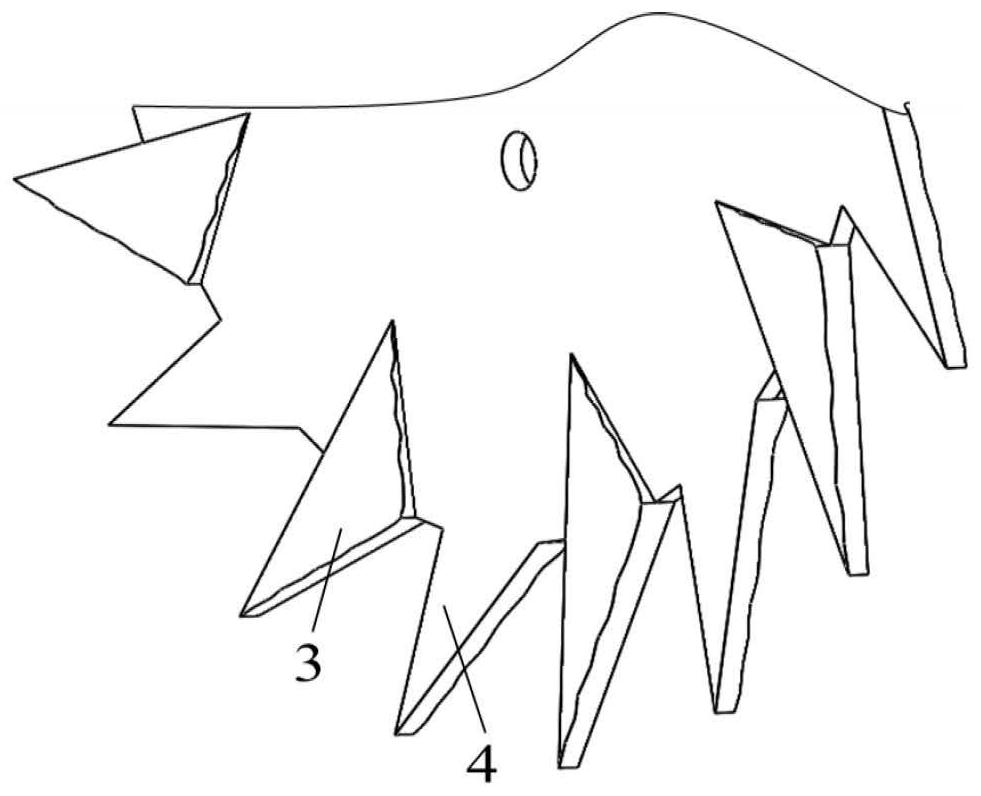

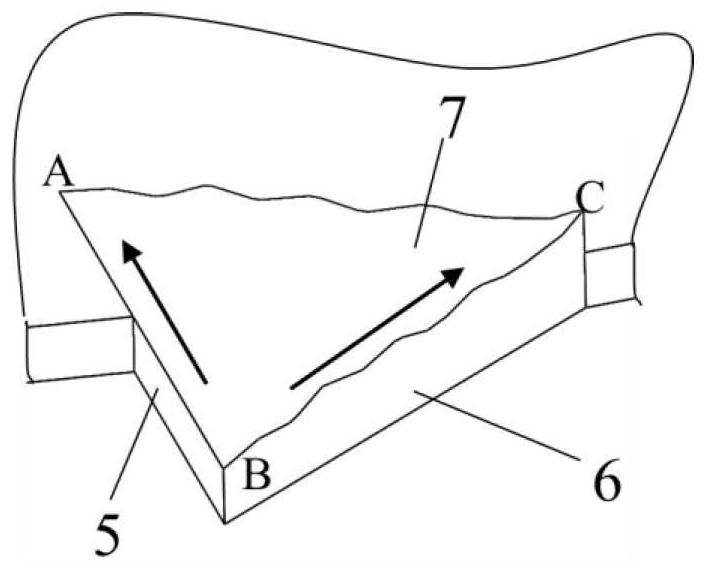

[0010] A local self-vibrating disc opener with three-way spline curve fitting teeth, the part is mainly composed of a disc main body 1 and a ditching tooth 2, wherein the ditching tooth 2 is centered on the geometric center of the disc main body 1 The center of the circle is uniformly arranged in the circumferential direction, and the slotting teeth 2 are divided into left slotting teeth 3 and right slotting teeth 4, which are adjacently staggered and symmetrically arranged according to the tooth surface shape. The slotting tooth 2 includes a front edge surface 5, a rear edge surface 6 and a spline curve fitting ABC surface 7, the angle δ between the front edge surface 5 and the radial line of the disc main body 1 is 16° to 21°, and the rear edge surface 6 The included angle θ with the radial line of the disc main body 1 is 37.5°~42.5°, and the spline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com