Drilling bit spiral impact device

A technology of impact device and drill bit, which is applied to driving devices for drilling in wellbore, drilling equipment, earth-moving drilling, etc. , increase the effect of the rock crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

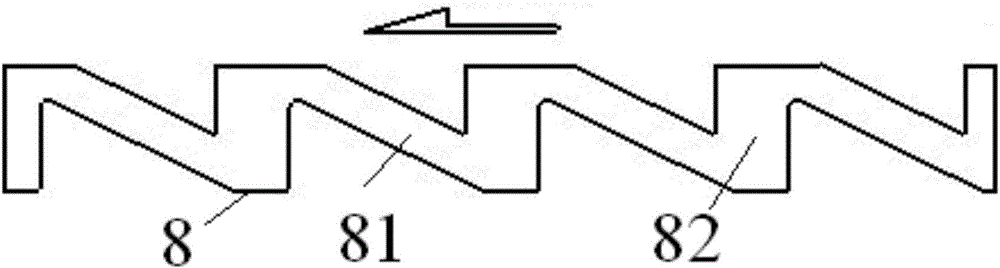

[0021] Embodiment 1: a kind of drill bit spiral impact device, such as figure 1 and figure 2 As shown, it includes an outer casing 1, an impact hammer 3 installed in the outer casing in the vertical direction and a lower joint 5 connected to the drill bit. The outer casing includes an upper casing and a lower casing positioned below the upper casing. The bushing and the lower bushing are connected through a guide sleeve 4 located between them, and the two ends of the guide bush are respectively threaded with the upper bushing and the lower bushing, and the center of the impact hammer is provided with a power input shaft that drives the impact hammer to rotate 2. The center of the impact hammer is provided with a blind hole 6 with the same cross-sectional shape as the lower end of the power input shaft and a drain hole 7 connected to the blind hole. The liquid outlet of the drain hole is located on the outer surface of the impact hammer, and the power input The lower end of t...

Embodiment 2

[0023] Embodiment 2: a kind of drill bit spiral impact device, such as Figure 4 As shown, it includes an outer casing 1, an impact hammer 3 installed in the outer casing in the vertical direction and a lower joint 5 connected to the drill bit. The outer casing includes an upper casing and a lower casing positioned below the upper casing. The bushing and the lower bushing are connected through a guide sleeve 4 located between them, and the two ends of the guide bush are respectively threaded with the upper bushing and the lower bushing, and the center of the impact hammer is provided with a power input shaft that drives the impact hammer to rotate 2. The center of the impact hammer is provided with a blind hole 6 with the same cross-sectional shape as the lower end of the power input shaft and a drain hole 7 connected to the blind hole. The liquid outlet of the drain hole is located on the outer surface of the impact hammer, and the power input The shaft is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com