Microbial sample processing and scribing system and method

A technology of microorganisms and samples, which is applied to the sampling method of biological materials, biochemical equipment and methods, biochemical instruments, etc., can solve the problems of high labor cost and low efficiency, large randomness of manual operation, and unstandardized operation, etc., and achieve the operation process Effects of standardized mechanization, biosafety problem solving, and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

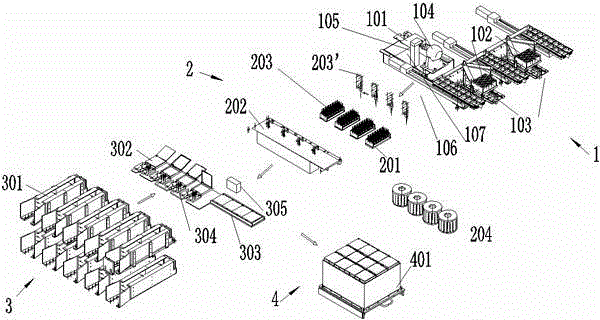

[0093] The scribing component 2 is the scribing component 2 of Embodiment 1, and other components remain unchanged. During specific implementation, the scribing assembly 2 includes a scribing pen placement platform 201, a scribing pen discarding place 202, a scribing pen A 203 and a cantilever. Move the scribe pen A 203 between the base scribe station 302 and the dipping sample place 106, the cantilever is also provided with a pick-up mechanism for picking up the scribe pen A 203, and the scribe pen placement table 201 is used for placing the scribe pen to enter the scribe line. For the boxed scribe pens of component 2, the scribe pen discard place 202 is used to store the scribe pens that have been marked on the culture medium. In order to better reflect the advantages of this embodiment, the scribe pen A 203 is a one-time use scribe pen.

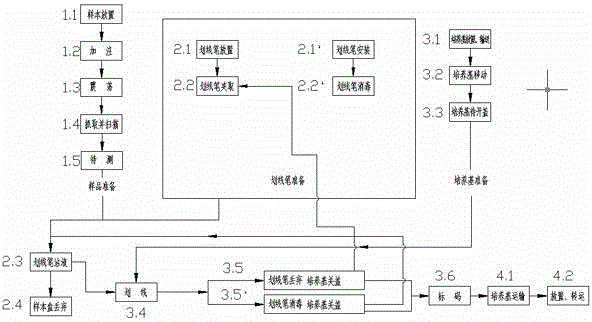

[0094] Correspondingly, the streaking method for microbial sample processing is as follows:

[0095] 1. Sample preparation, the steps i...

specific Embodiment 2

[0116] The scribing component 2 is the scribing component 2 of the second embodiment, and other components remain unchanged. During specific implementation, the marking assembly 2 includes a marking pen B 203 ′, a disinfection device 204 and a cantilever, and the cantilever is used to move the marking pen B 203 between the disinfection device 204, the culture medium marking platform 302 and the sample place 106 ', the cantilever is also provided with a connecting mechanism for fixed connection with the scribe pen B 203', and the disinfection device 204 is used for sterilizing the scribe pen B 203'. In order to better reflect the advantages of this embodiment, the scribe pen B 203' is a reusable scribe pen.

[0117] Correspondingly, the streaking method for microbial sample processing is

[0118] 1. Sample preparation, the steps include:

[0119] 1.1. Sample placement, that is, the sample box that has been collected and coded in the previous stage is placed on the platform at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com