Method for producing organic fertilizer from livestock manure in a harmless manner

A technology of livestock and poultry manure and organic fertilizer, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts. It can solve problems such as environmental pollution, factory odor, and long fermentation time, so as to reduce environmental pollution and reduce odor. , the effect of low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for harmlessly producing organic fertilizer from livestock and poultry manure, comprising the following steps:

[0033] Step 1. Evenly sprinkle the fermented microbial strains on the fresh pig manure in the cesspool of the pig farm with a water content greater than 70%, without stirring; wherein, during the sprinkling process, control the mass ratio of the fresh livestock and poultry manure and the fermented microbial strains The ratio is 1000:1, and the frequency of sprinkling is once every 2 days.

[0034] Step 2. The first day of fermenting microbial strains is recorded as the first day. After 1 to 2 days of fermentation, use a dry-wet separator to dehydrate and adjust the water content of livestock and poultry manure to 50% to 60%, and complete the pretreatment. Obtain pretreated pig manure.

[0035] Step 3: Transport the pretreated pig manure obtained in step 2 to a fermentation tank, and add 20% of the pretreated pig manure as an auxiliary material to ad...

Embodiment 2

[0038] A method for harmlessly producing organic fertilizer from livestock and poultry manure, comprising the following steps:

[0039] Step 1. Evenly sprinkle the fermented microbial strains on the fresh cow manure in the cesspool of the cattle farm with a water content of 50% to 70%, without stirring; wherein, during the sprinkling process, control the fresh livestock and poultry manure and the fermented microbial strains The mass ratio is 1000:2, and the frequency of sprinkling is once every 3 to 4 days.

[0040] Step 2. The first day is recorded as the first day when the microbial strains are sprinkled for the first time. After 3 to 4 days of fermentation, the water content of livestock and poultry manure is adjusted to 50% by adding auxiliary materials, and the pretreatment is completed to obtain the pretreated cow dung.

[0041] Step 3, transporting the pretreated cow manure obtained in step 2 to the fermentation tank, and adding 10% of the pretreated pig manure as an a...

Embodiment 3

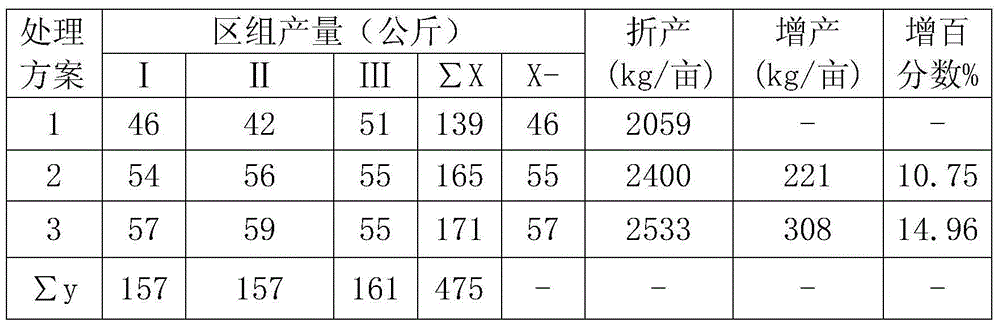

[0044] The test of the organic fertilizer produced in Embodiment 1 using cabbage and cauliflower in Ducheng Town, Huangzhou District, Huanggang City

[0045] Test conditions:

[0046] Test crops: head cabbage, cauliflower.

[0047] Organic fertilizer for testing: the organic fertilizer produced in Example 1. Specification 40kg / bag, content of organic matter ≥ 57%,

[0048] NPK≥5.6%, moisture 22%.

[0049] Test treatment plan:

[0050] ① Control (apply 30kg of compound fertilizer per mu, 15kg for bottom application and topdressing).

[0051] ② Control + base application of organic fertilizer 50kg / mu;

[0052] ③ Control + base application of organic fertilizer 100kg / mu.

[0053] Experimental results: the average yield of cabbage and cauliflower plots was analyzed by variance, and the difference between treatments was extremely significant. The yield of cabbage with 50kg of organic fertilizer increased by 114kg / mu, 3.4% compared with the control; the yield of cabbage with 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com