Titanium dioxide hollow sphere constructed by nanorods and preparation method and application thereof

A technology of titanium dioxide and nanorods, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as limited applications, and achieve the effects of storage and penetration, good structural stability, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

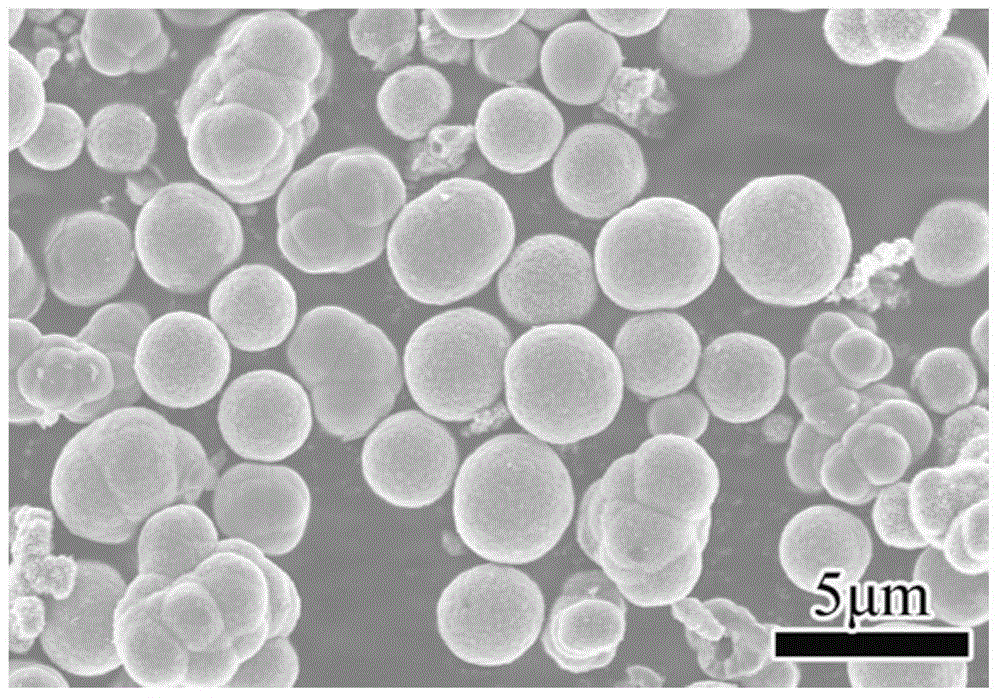

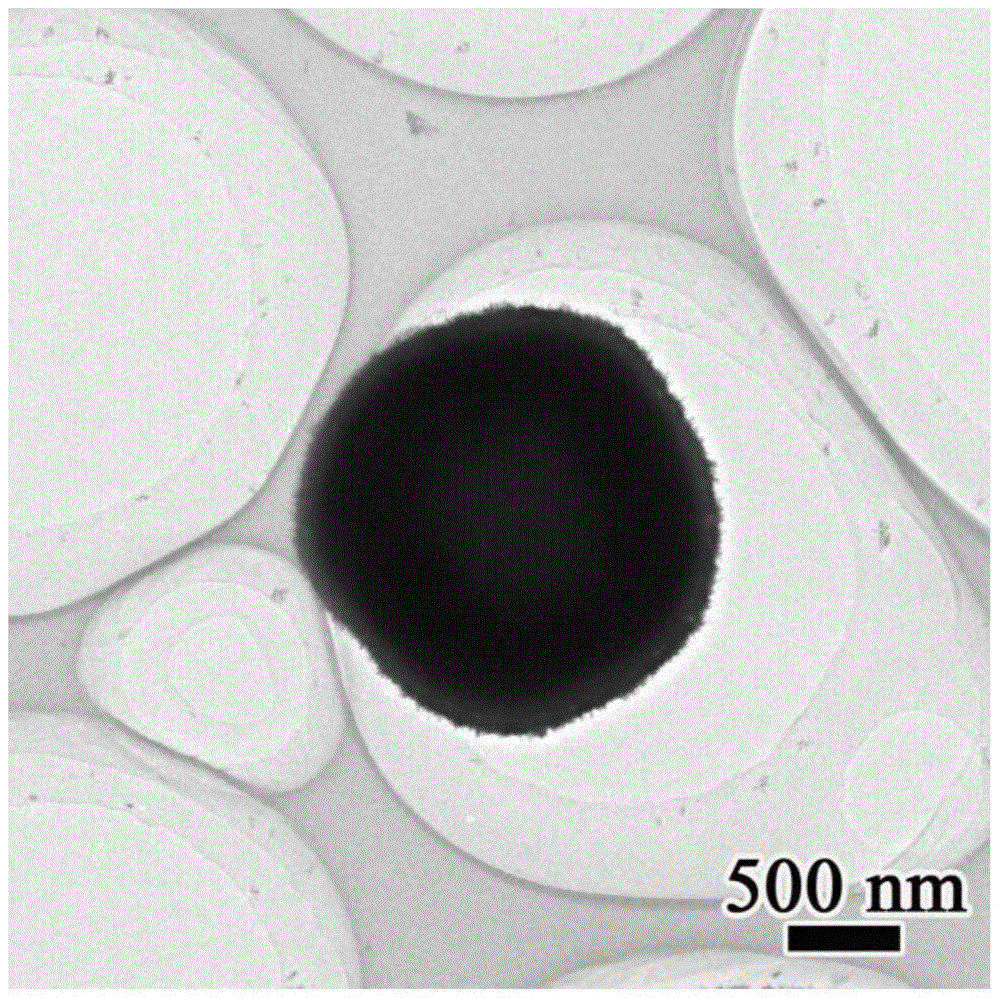

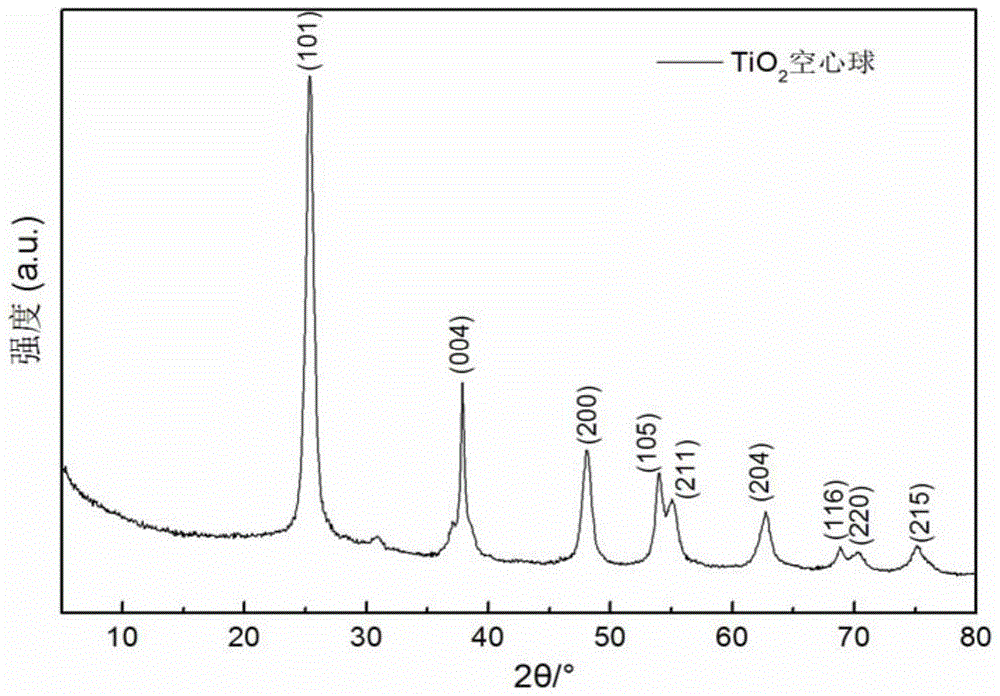

[0038] Add 1.5 mL of titanium tetrachloride to 84 mL of isopropanol and stir for 30 minutes. The above solution was transferred to a 150mL reactor and reacted at 200°C for 24 hours. Then, the obtained product is repeatedly washed with ethanol, centrifuged and dried to obtain titanium dioxide hollow spheres constructed of nanorods. Titanium dioxide hollow spheres have a diameter of 1.5 μm, a shell thickness of 400-500 nm, a cavity size of about 500 nm, and a specific surface area of 43.8 m 2 g -1 . In addition, the shell consists of a large number of radial nanorods with a nanorod size of ~15 nm. The hollow structure titanium dioxide crystal form is anatase phase.

[0039] figure 1 It is the scanning electron microscope picture of the core-shell structure titanium dioxide constructed by nanosheets, figure 2 is the TEM image of the material, image 3 is the XRD pattern of the material, Figure 4 is the nitrogen adsorption-desorption curve of the material, the specific...

Embodiment 2

[0042] Add 1.5 mL of titanium tetrachloride to 84 mL of isopropanol and stir for 30 minutes. The above solution was transferred to a 150mL reactor and reacted at 200°C for 3 hours. Then, the obtained product is repeatedly washed with ethanol, centrifuged and dried to obtain titanium dioxide hollow spheres constructed of nanorods. Figure 6 It is the scanning electron micrograph of embodiment 2. The diameter of the titanium dioxide core-shell structure is about 4 μm, the thickness of the shell layer is 1 μm, and the diameter of the core part is about 1.8 μm. In addition, the shell consists of a large number of radiating nanorods with a nanorod size of ~15 nm.

Embodiment 3

[0044] Add 1.5 mL of titanium tetrachloride to 84 mL of isopropanol and stir for 30 minutes. The above solution was transferred to a 150mL reactor and reacted at 200°C for 9 hours. Then, the obtained product is repeatedly washed with ethanol, centrifuged and dried to obtain titanium dioxide hollow spheres constructed of nanorods. Figure 7 It is the scanning electron micrograph of embodiment 3. The diameter of the titanium dioxide hollow sphere is about 2 μm. In addition, the shell consists of a large number of radiating nanorods with a nanorod size of ~15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com