A high-voltage intercalation assembly method and its application in the field of preparation of intercalation structure composite materials

A composite material and intercalation technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of complex process, pollution, waste of water resources and the environment, and achieve the effect of simple process and increased solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A: Add industrial grade Mg(OH) 2 Add AlOOH and Mg / Al molar ratio = 2 / 1 into the ball mill tank, then put it into the ball mill and grind for 2 hours, take out the sample for later use;

[0021] B: Add lauric acid (LA for short) to 80ml deionized water according to LA / Al=1 / 1, then add the mixture sample in step A, Mg(OH) 2 The total mass fraction of AlOOH and AlOOH is 0.5%, ultrasonic and stirred for 10min;

[0022] C: Transfer the suspension mixed in step B to the autoclave, stir for 1 hour, then raise the temperature to 150°C, first pressurize to 0.8MPa, stir for 6 hours; continue to pressurize to 1.0MPa, stir for 6 hours, and finally pressurize to 1.5 MPa, after stirring for 10 hours, take it out, and after centrifugation, put the sample into an oven at 60°C for drying to obtain the intercalation structure composite material MgAl-LA-LDHs.

[0023] The pressurization method is to feed nitrogen into the pressurization.

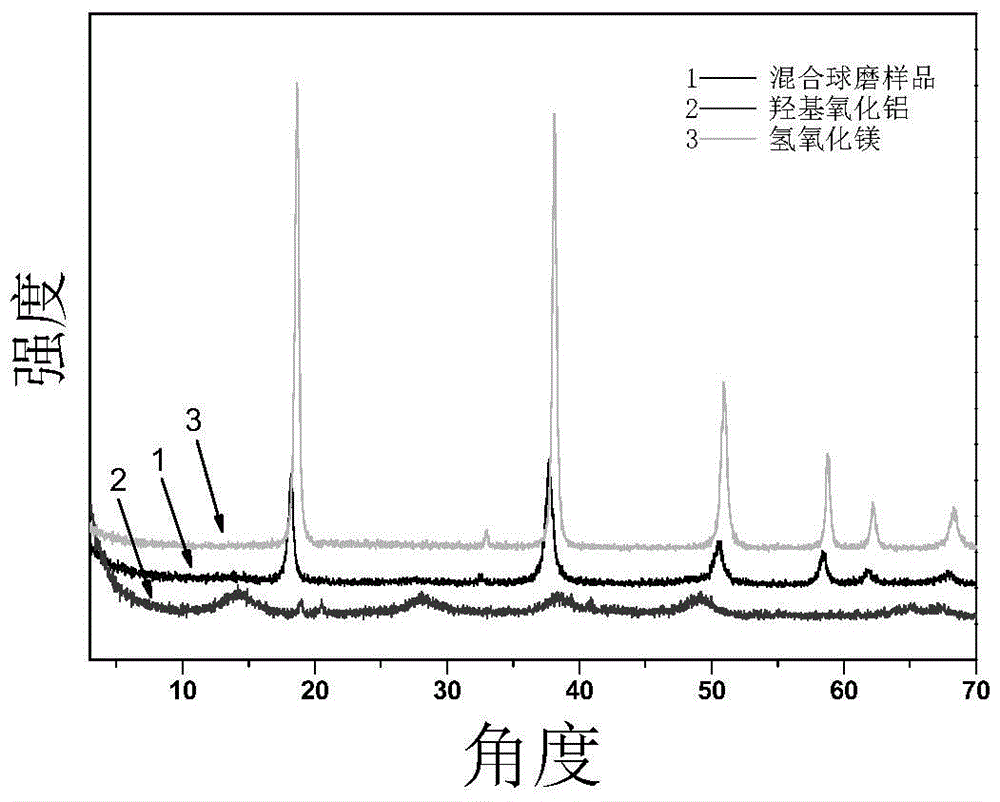

[0024] Such as figure 1 Shown, where line 1 i...

Embodiment 2

[0026] A: Mg(OH) 2 Add AlOOH and Mg / Al=2 / 1 into the ball mill tank, then put it into the ball mill and grind for 3 hours, take out the sample for later use;

[0027] B: Add lauric acid to 80ml deionized water according to LA / Al=1 / 1, then add the mixture sample in step A, Mg(OH) 2 The total mass fraction of AlOOH and AlOOH is 2.0%, ultrasonic and stirred for 10min;

[0028] C: Transfer the suspension mixed in step B to the autoclave, stir for 1 hour, then raise the temperature to 150°C, first pressurize to 0.8MPa, stir for 6 hours; continue to pressurize to 2.0MPa, stir for 6 hours, and finally pressurize to 3.0 MPa, after 10 hours of stirring reaction, take it out, after centrifugation, put the sample into a 60°C oven to dry, and then obtain the intercalation structure composite material MgAl-LA-LDHs.

[0029] The pressurization method is to feed nitrogen into the pressurization.

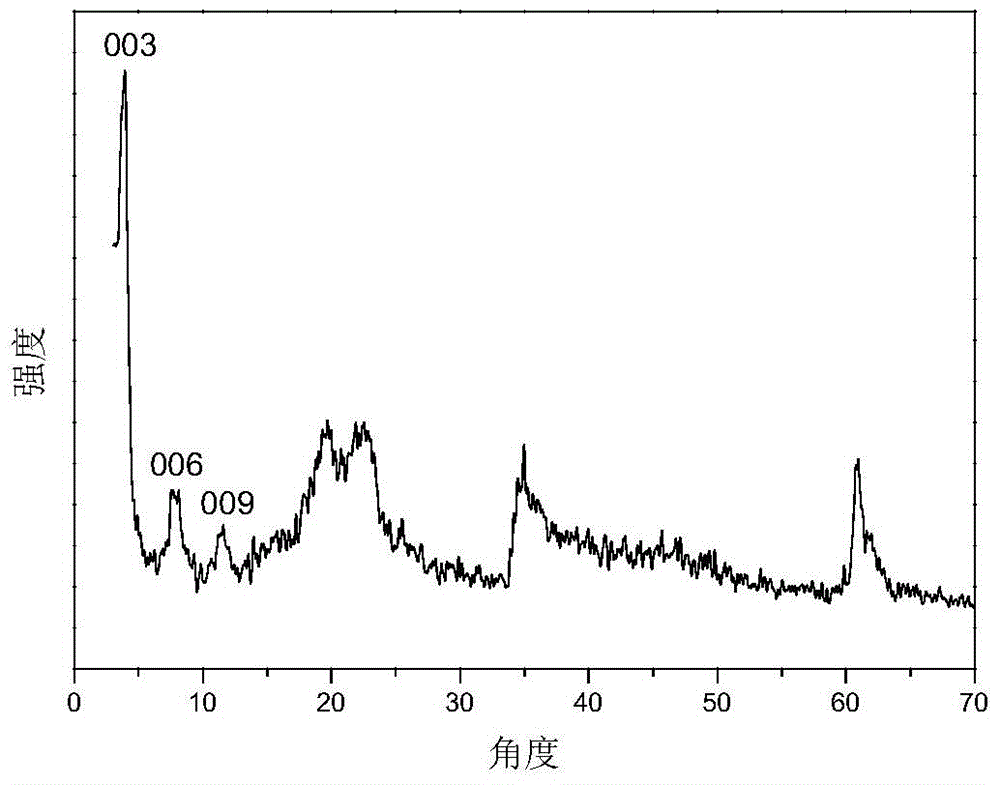

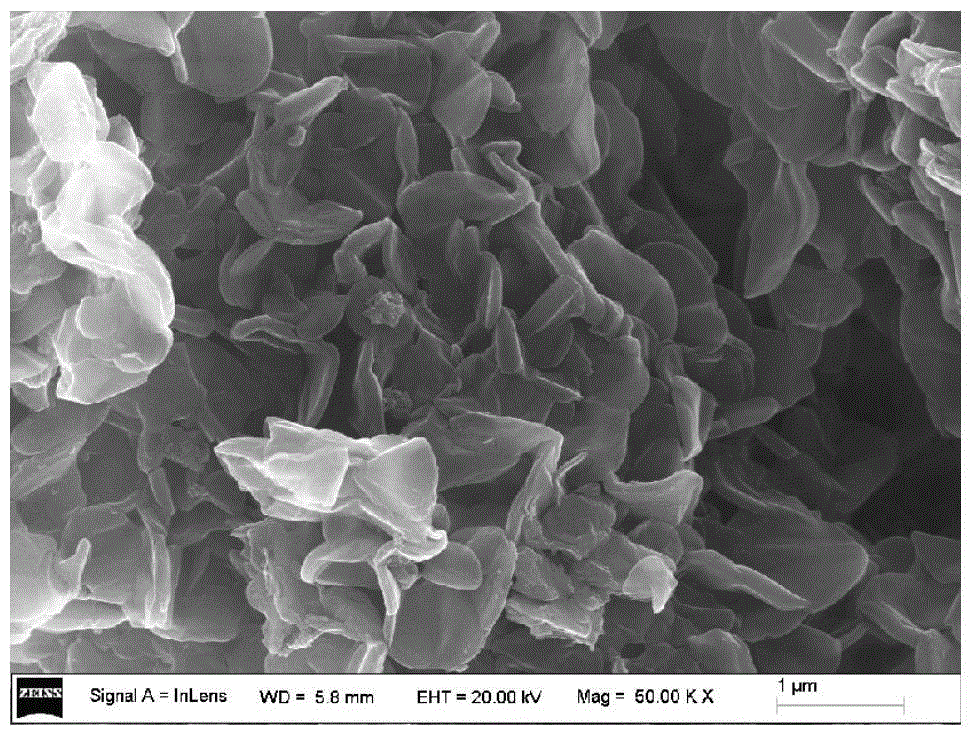

[0030] Characterized: the hydrotalcite prepared under the above conditions has a good crystal...

Embodiment 3

[0032] A: Mg(OH) 2 Add AlOOH and Mg / Al=3 / 1 into the ball mill tank, then put it into the ball mill and grind for 2 hours, take out the sample for later use;

[0033] B: Add lauric acid to 80ml deionized water according to LA / Al=1 / 1, then add the mixture sample in step A, Mg(OH) 2 The total mass fraction of AlOOH and AlOOH is 5.0%, ultrasonic and stirred for 10 min.

[0034]C: Transfer the suspension mixed in step B to an autoclave, stir for 1 hour, then raise the temperature to 150°C, first pressurize to 1.0MPa, stir for 6 hours; continue to pressurize to 2.0MPa, stir for 6 hours, and finally pressurize to 4.0 MPa, after 10 hours of stirring reaction, take it out, and after centrifugation, put the sample into an oven at 60°C to dry to obtain the intercalation structure composite material MgAl-LA-LDHs.

[0035] The pressurization method is to feed nitrogen into the pressurization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com